Method for preparing of high purity acarbose

A technology of acarbose and acarbose, applied in the field of preparation of high-purity acarbose, can solve the problems of high removal cost, low yield, and high impurity A, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] First put the acarbose feed liquid in the tank and wrap the used glass column tightly with cotton. The interlayer of the glass column is filled with frozen water. The filter equipment used and the bucket or beaker for storing the feed liquid are placed in ice cooling. In order to ensure the insulation effect as much as possible. At the same time, the temperature of the feed liquid is monitored by a thermometer.

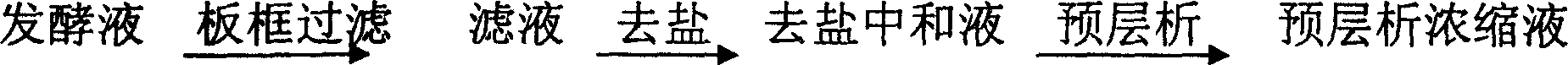

[0024] After fermentation, the acarbose feed liquid is put into tanks, and plate and frame filtration, resin desalination and resin pre-chromatography are performed. During the whole process, the storage tanks and pipelines are insulated, and plate heat exchangers are installed in the pipelines. The device cools down. At the same time, the temperature of the feed liquid is strictly controlled by a thermometer. If the temperature is too high, increase the flow of chilled water or add ice cubes.

[0025] Through the above control, the temperature of the feed li...

Embodiment 2

[0032] First put the acarbose feed liquid into the tank to get the acarbose feed liquid to pass through the feed liquid pipeline and the storage tank with a polypropylene foam tube and wrap the skin tightly with aluminum skin to ensure the heat preservation effect as much as possible. At the same time, stainless steel spiral plate heat exchangers and temperature probes are installed in each feed liquid pipeline.

[0033] After fermentation, put the acarbose feed liquid into the tank, and perform plate-and-frame filtration, resin desalination and resin pre-chromatography operations. During the whole process, the storage tank and pipelines are kept warm, and heat exchangers are installed in the pipelines for further processing. Cool down. At the same time, the temperature of the feed liquid is strictly controlled through the temperature probe. If the temperature is too high, the flow of chilled water should be increased.

[0034] Through the above control, the temperature of th...

Embodiment 3

[0041] First put the acarbose feed liquid into the tank to obtain the acarbose feed liquid, and wrap the feed liquid pipeline and the storage tank with rubber and plastic materials tightly with adhesive tape to ensure the heat preservation effect as much as possible. At the same time, stainless steel spiral plate heat exchangers and temperature probes are installed in each feed liquid pipeline.

[0042] After fermentation, put the acarbose feed liquid into the tank, and perform plate-and-frame filtration, resin desalination and resin pre-chromatography operations. During the whole process, the storage tank and pipelines are kept warm, and heat exchangers are installed in the pipelines for further processing. Cool down. At the same time, the temperature of the feed liquid is strictly controlled through the temperature probe. If the temperature is too high, the flow rate of the ice brine is increased.

[0043] Through the above control, the temperature of the feed liquid is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com