Light-adjusting and power distribution system used in full-function telestudio stage

A technology for power distribution systems and studios, applied in the field of studio control systems, can solve the problems of discrete equipment, heavy workload of staff, high production and maintenance costs, and achieve the effect of avoiding safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

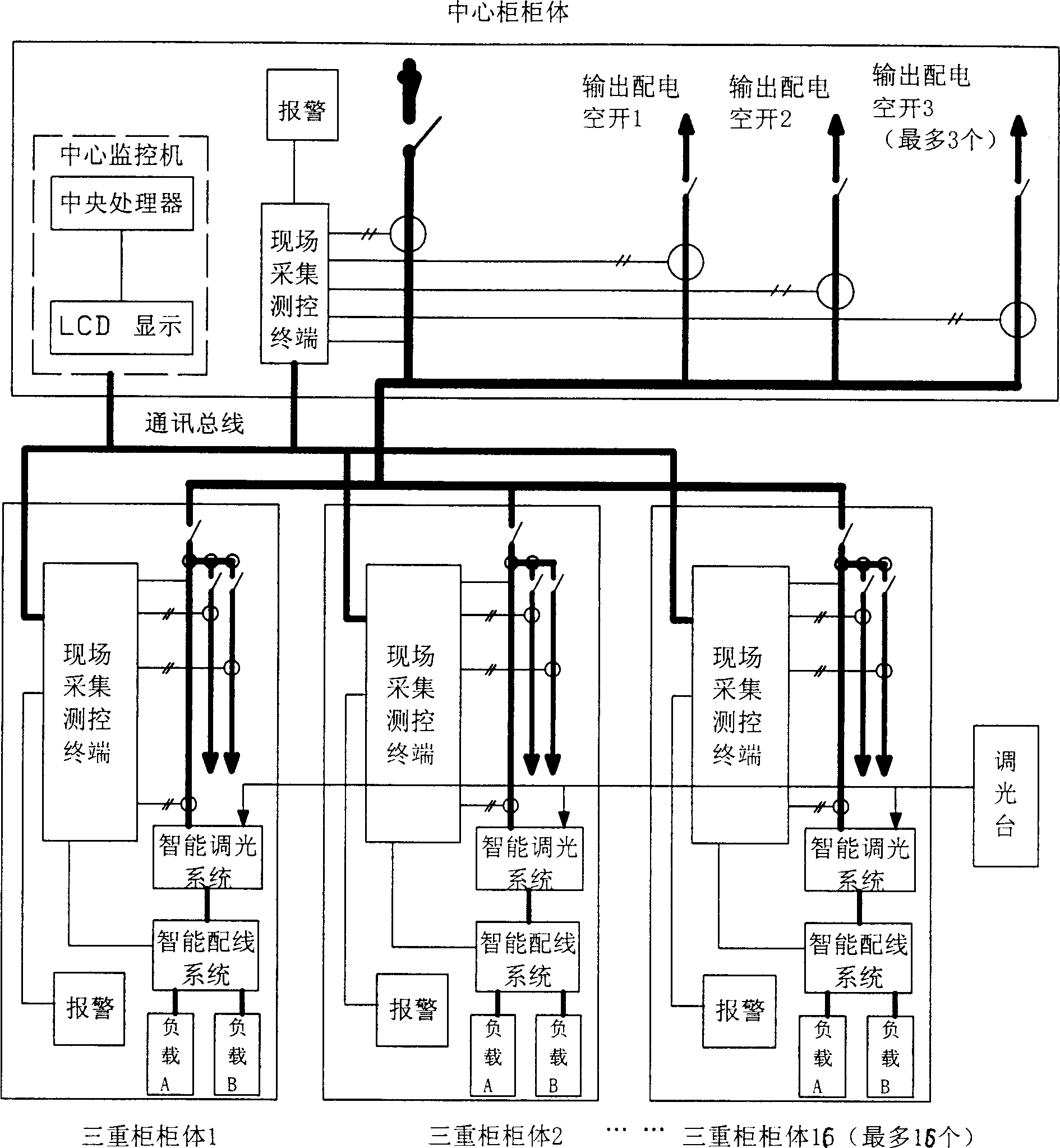

[0014] The invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0015] The central monitoring machine of the present invention collects information such as operating parameters and working status of the power distribution cabinet in the central cabinet, the dimming module and the wiring module in the triple cabinet cabinet in real time through on-site collection of measurement and control terminals and high-speed communication buses. And through the friendly man-machine interface, the load line is connected, and the power consumption limit and excess sound and light alarm can be set according to the user's requirements; the current of each triple cabinet and the power distribution cabinet in the central cabinet can be displayed on the LCD screen , voltage, actual power consumption, remaining power, power harmonic components, temperature, load terminal matching table, terminal matching interface, alarm interface, et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com