High-strength ultra-thin stainless steel container

A technology of stainless steel and volumetric tank, applied in a stainless steel field, to achieve balanced force, strong load resistance, and good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

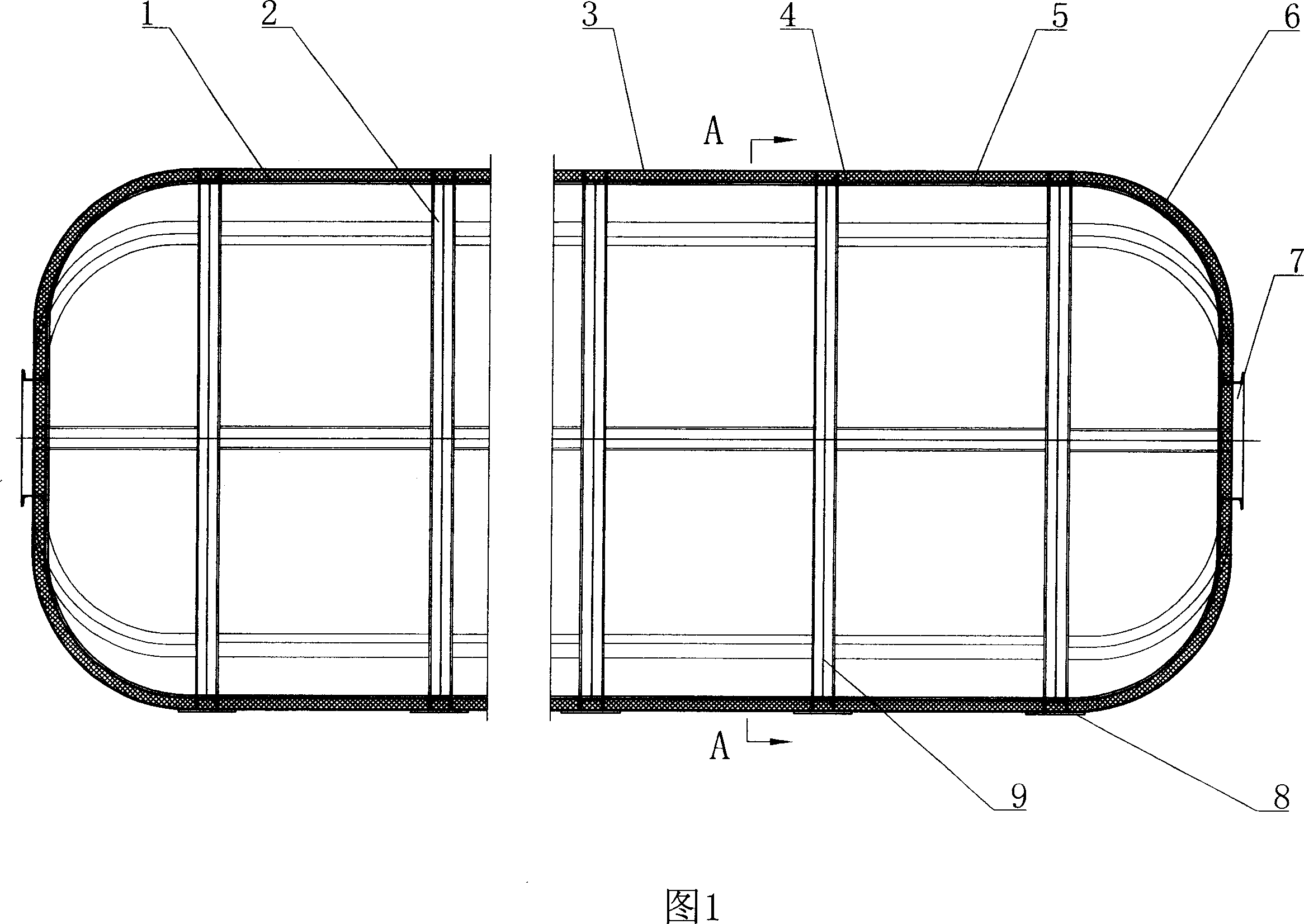

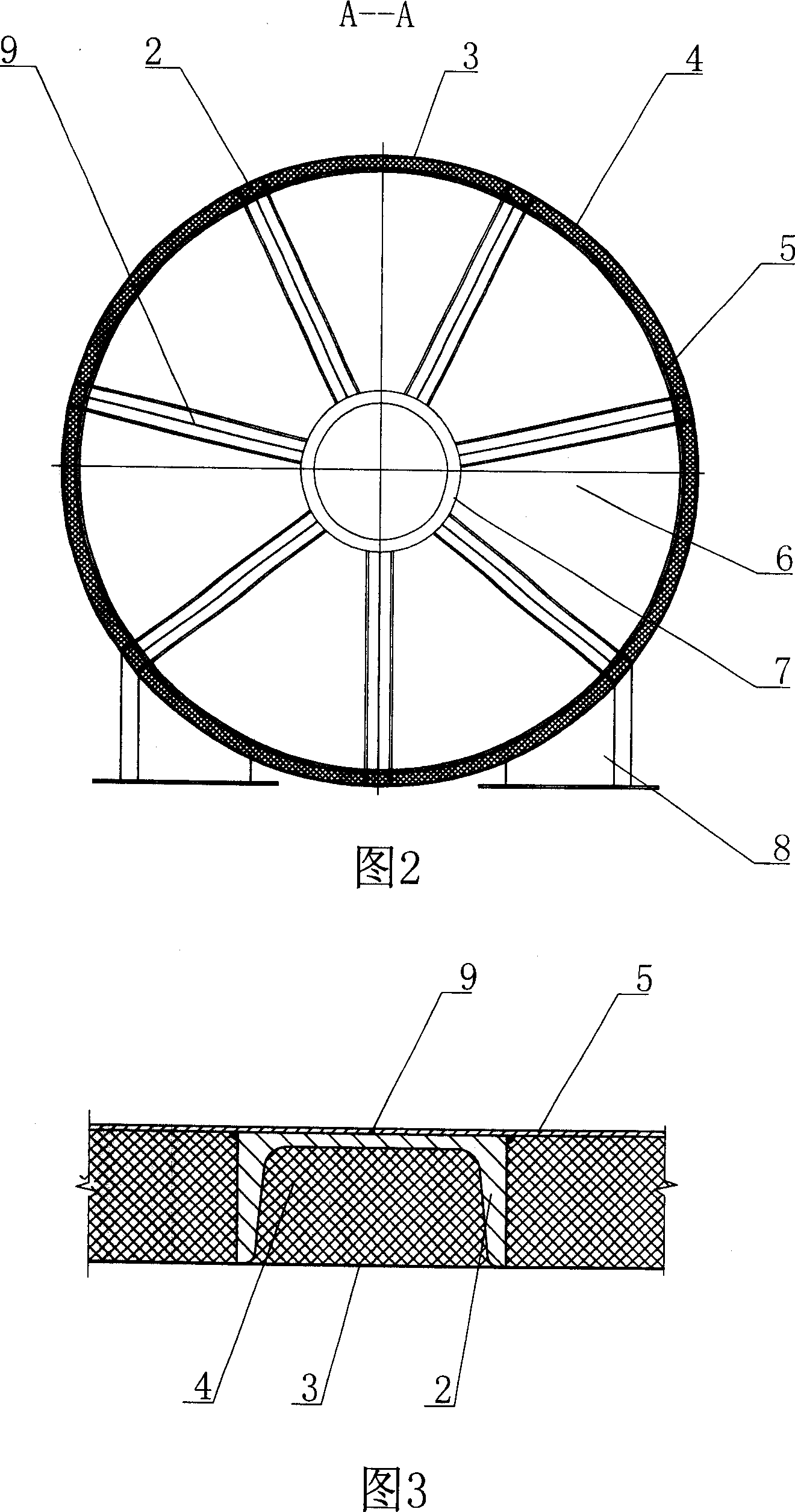

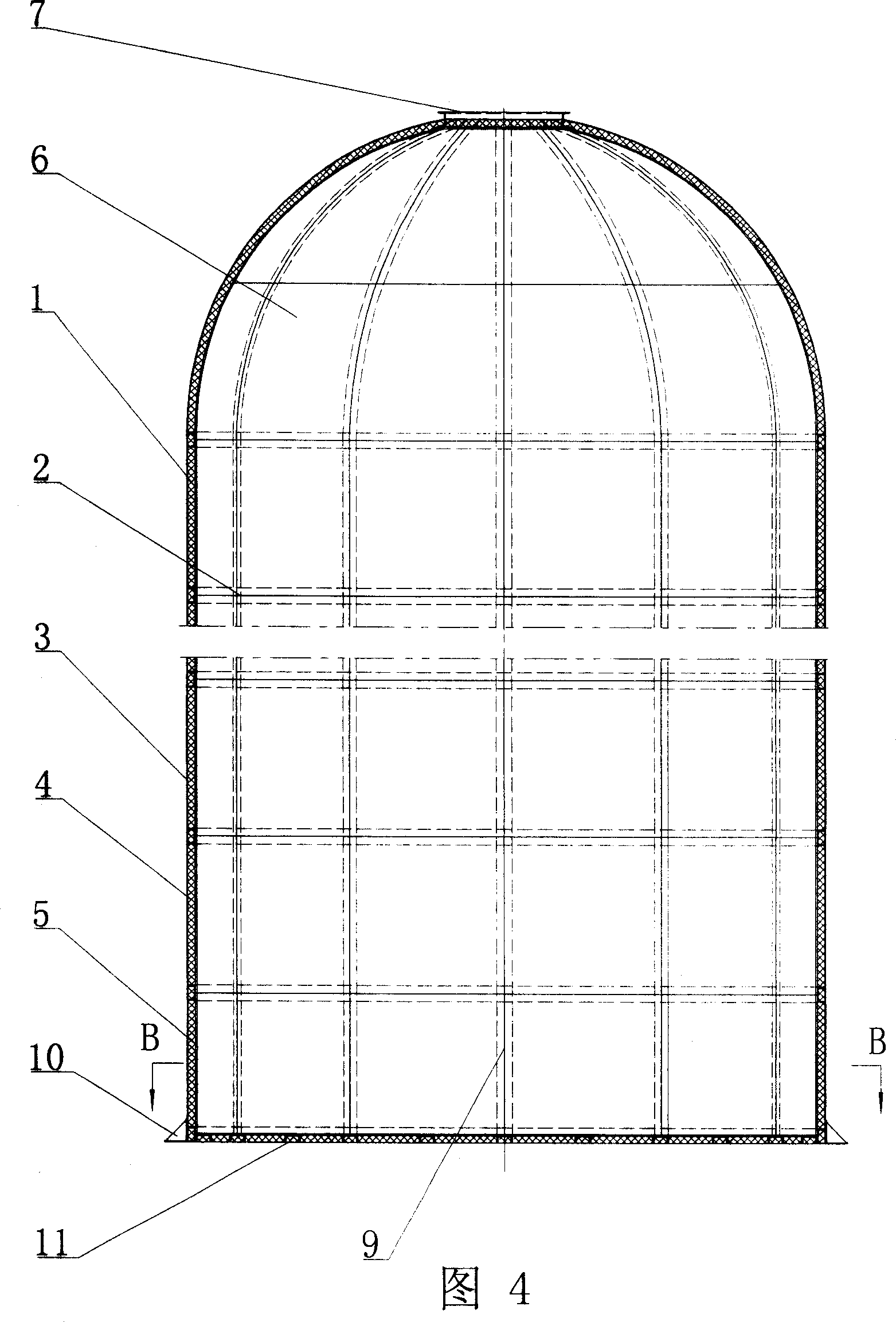

[0019] The specific structure and working process of the present invention will be described in detail according to Fig. 1-7. The capacity tank includes a tank body provided with a material inlet, a material outlet and inlet and outlet gate valves. The specifications and shapes of the inlet and outlet of the tank body and their inlet and outlet gate valves are not shown in the figure, and can be determined according to the specific use and actual use requirements of the volumetric tank. The specifications of the tank body can be made into horizontal structure (as shown in Figure 1), vertical structure (as shown in Figure 4), bottom and upper circular structure (as shown in Figure 6) and other forms according to actual use requirements. The horizontal structure is composed of the body 1, the two ends of the head 6 and the support 8; the vertical structure and the lower upper circle structure are composed of the body 1, the upper head 6 and the lower bottom cover 11, and the bot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com