High-strength concrete accelerator

A technology of high-strength concrete and accelerator, applied in the field of building materials, can solve the problems of high cost and low strength of accelerator

Inactive Publication Date: 2007-08-08

葫芦岛市辽西混凝土外加剂有限公司

View PDF2 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] In order to solve the problems of low strength and high cost of existing concrete accelerators, the following technical scheme is proposed

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

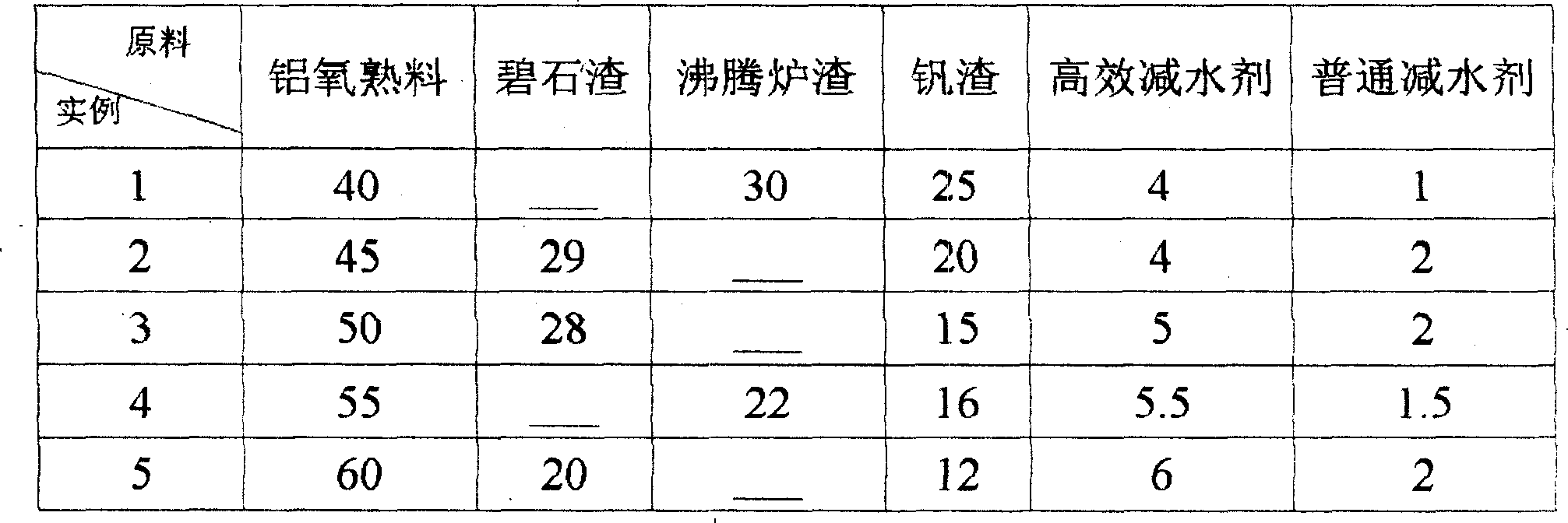

[0027] Table 3 high-strength concrete quick-setting admixture batching example (% by weight)

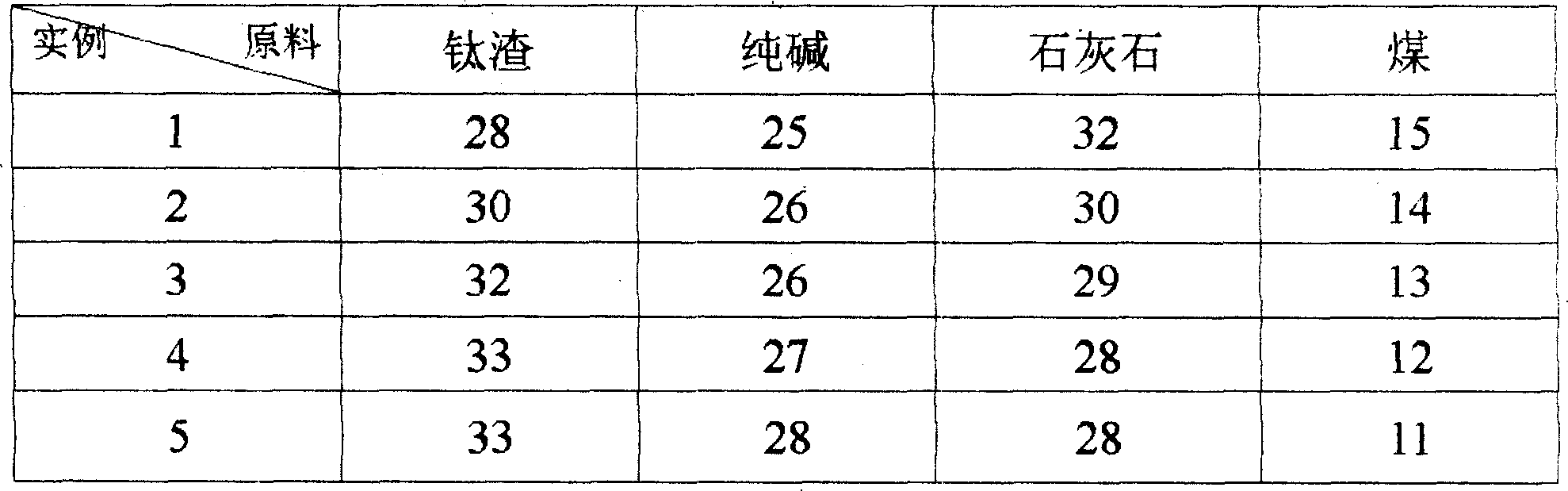

[0028] Table 4 Al-Oxygen clinker batching example (% by weight)

[0029] Note: The ash content of the raw coal used is 40%, and the calorific value is 15903KJ / Kg----18833kJ / kg.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a high-strength concrete accelerator, which comprises the following parts: 40-60% alundum clinker, 20-30% green stone slag or boiling stove slag, 12-25% vanadium slag, 4-6% high-effective dehydragent and 1-2% common dehydragent, wherein the alundum clinker is composed of 28--33% titanium slag, 25-28% pure alkaline, 28-32% limestone and 11-15% coal.

Description

technical field [0001] The invention belongs to the field of building materials, in particular to a high-strength shotcrete quick-setting agent. Background technique [0002] Most of the existing concrete accelerators have problems such as high cost and large strength loss rate in 28 days. It is composed of several high-priced chemical products such as sodium chloride and cellulose, which not only has high cost, but also has the same technical performance as the commonly used accelerator except for early strength. Another example is CN1194926C "Spraying Concrete Accelerator". The quick-setting agent is made by mixing, stirring and grinding aluminum-oxygen clinker and boiling slag. Oxygen clinker is basically the same, except that industrial waste - boiling slag is used in the final grinding of the finished product, which saves resources and reduces costs, but its technical performance is comparable to that of commonly used accelerators. At present, the development trend of...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B22/00

CPCC04B2201/50C04B2103/12C04B18/025C04B40/0039Y02W30/91C04B14/022C04B14/26C04B14/28C04B14/303C04B18/144C04B18/12C04B28/02C04B2103/302C04B18/067

Inventor 鞠秉秀詹学斌詹乐

Owner 葫芦岛市辽西混凝土外加剂有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com