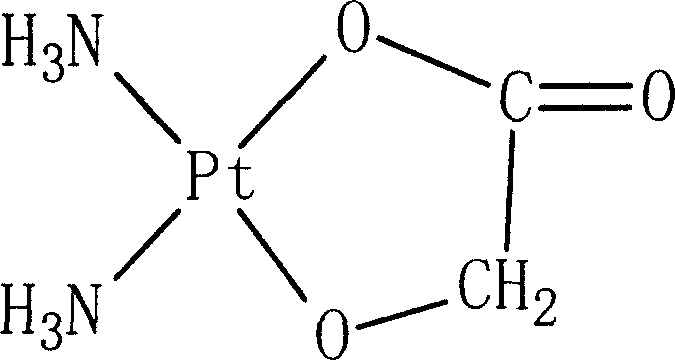

Method of preparing nedaplatin with ultra-low content of silver

A nedaplatin, extremely low technology, applied in the field of preparation of nedaplatin with extremely low silver content, can solve the problems of unstable product quality, low silver content of nedaplatin, high silver content of nedaplatin, etc. Achieve the effects of easy industrial production, extremely low silver content, and reduced deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

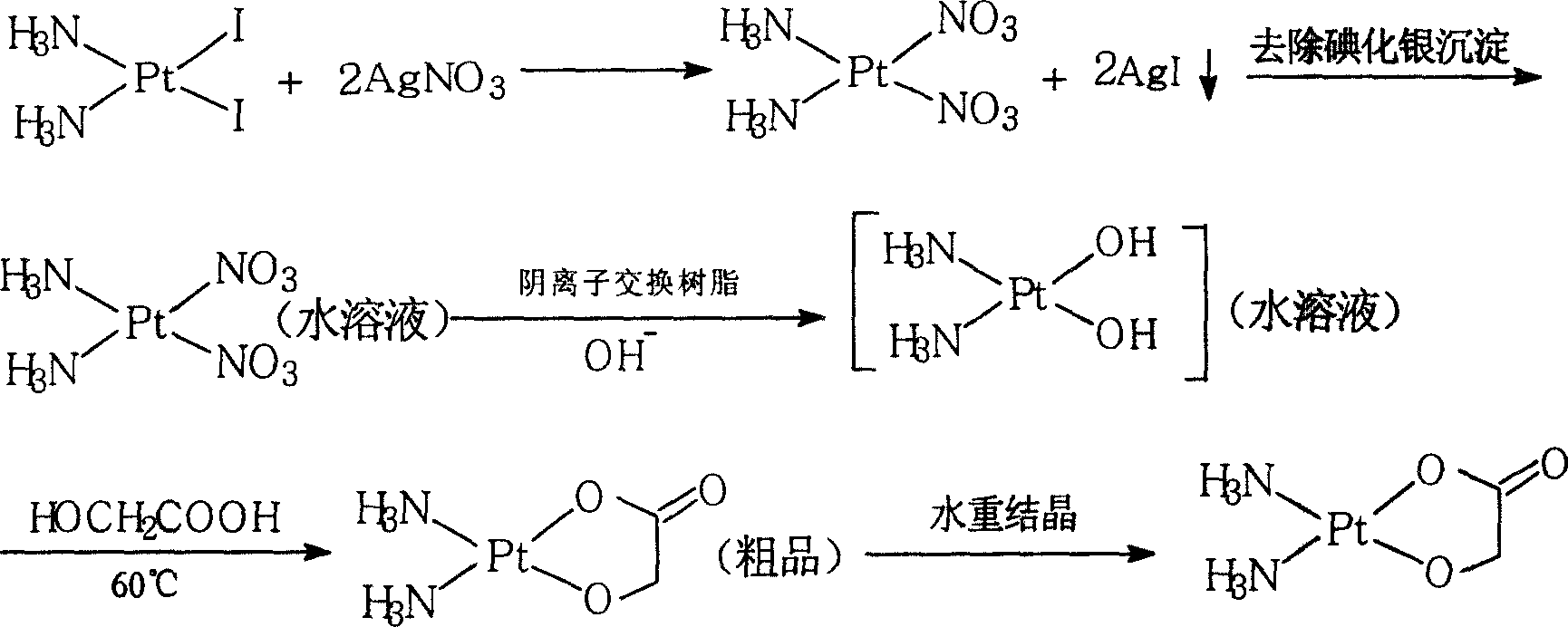

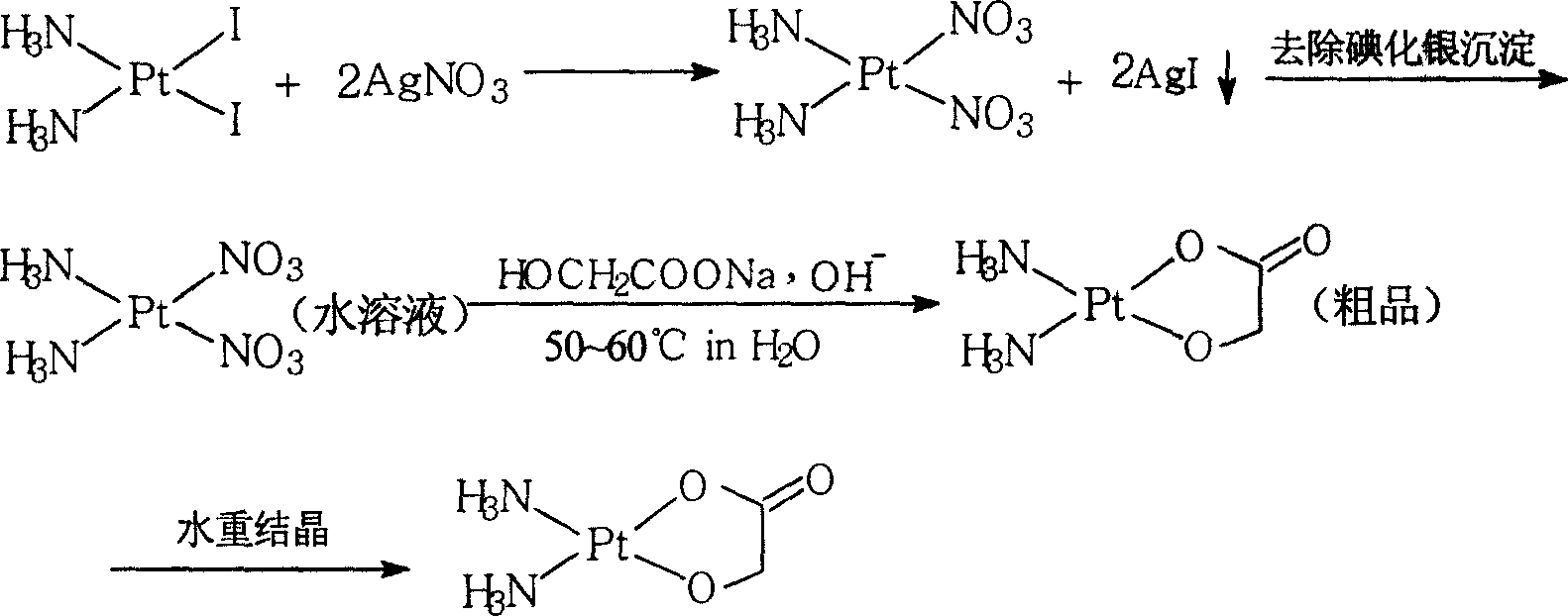

Method used

Image

Examples

Embodiment 1

[0018] Add 9.7g (0.02mol) cis-diiododiammine platinum and 30ml water into the reaction flask, stir and mix well, add 6.8g AgNO 3 (0.04mol) dissolved in 40ml of water, the brown-yellow precipitate in the reaction flask turned into pale yellow precipitate, stirred at 20°C for 5 hours, suction filtered to remove the silver iodide, 0.2g potassium iodide (1.2mmol) was added to the filtrate, 20 The reaction was stirred at °C for 1 hour, filtered through a membrane filter, 2g sodium glycolate (0.02mol) was added to the filtrate, the pH was adjusted to neutral with 2N NaOH solution, the temperature was raised to 60 °C, the reaction was stirred for 10 hours, and concentrated under reduced pressure to precipitate a solid , Filtered and dried to obtain 3.4 g of nedaplatin, yield: 56%.

[0019] Detected by atomic absorption spectrophotometry, the silver content of nedaplatin is less than 3ppm; analyzed by high performance liquid chromatography, the content of nedaplatin is 99.65% and related ...

Embodiment 2

[0022] Prepared according to known technology: add 9.7g (0.02mol) cis-diiododiammine platinum and 30ml water into the reaction flask, stir and mix well, add 6.8g AgNO 3 (0.04mol) dissolved in 40ml of water, the brown-yellow precipitate in the reaction flask turned into a light yellow precipitate, stirred at 20°C for 5 hours, suction filtered to remove the silver iodide, and 2g sodium glycolate (0.02mol) was added to the filtrate The pH was adjusted to neutral with 2N NaOH solution, the temperature was raised to 60° C., the reaction was stirred for 3 hours, and concentrated under reduced pressure to precipitate a solid, which was filtered and dried to obtain 3.1 g of nedaplatin. Yield: 51%.

[0023] Detected by atomic absorption spectrophotometry, the silver content of nedaplatin is 300ppm; analyzed by high performance liquid chromatography, the content of nedaplatin is 98.93% and related substances are 0.99%.

Embodiment 3

[0025] Add 14.5g (0.03mol) cis-diiododiammine platinum and 45ml water to the reaction flask, stir and mix well, add 10.2g AgNO 3 (0.06mol) dissolved in 60ml water, stirred and reacted at 30°C for 5 hours, filtered with suction, 0.5g potassium iodide (3mmol) was added to the filtrate, stirred for 1 hour at 25°C, filtered through a membrane, and 2.9g glycolic acid was added to the filtrate Sodium (0.03mol), adjusted pH to neutral with 2N NaOH solution, heated to 60°C, stirred for 8 hours, concentrated under reduced pressure, and solid precipitated out, filtered and dried to obtain 5.4g of nedaplatin, yield: 59%.

[0026] Detected by atomic absorption spectrophotometry, the silver content of nedaplatin is less than 3ppm; analyzed by high performance liquid chromatography, the content of nedaplatin is 99.69%, and the related substance is 0.33%.

[0027] Elemental analysis of nedaplatin prepared in Example 2 and nedaplatin prepared in Example 3 is consistent with the elemental content ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com