Spinning nozzle

A technology for nozzles and yarns, which is applied in the direction of yarn, textiles and papermaking, and can solve the problems of easy-to-settling nozzles and lowering the quality of long yarns, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Embodiments of the present invention will be described hereinafter with reference to the accompanying drawings.

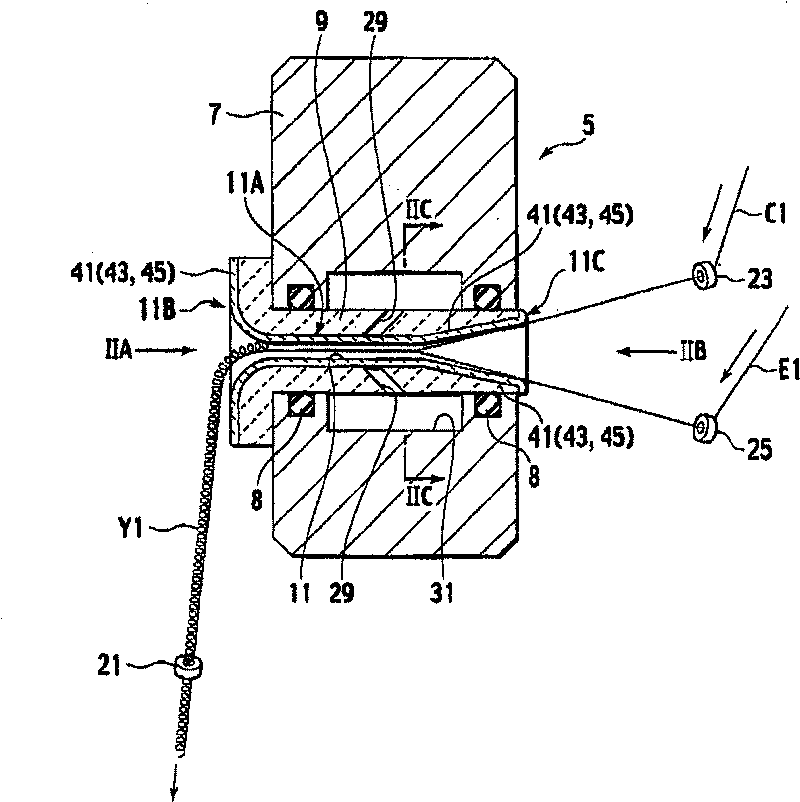

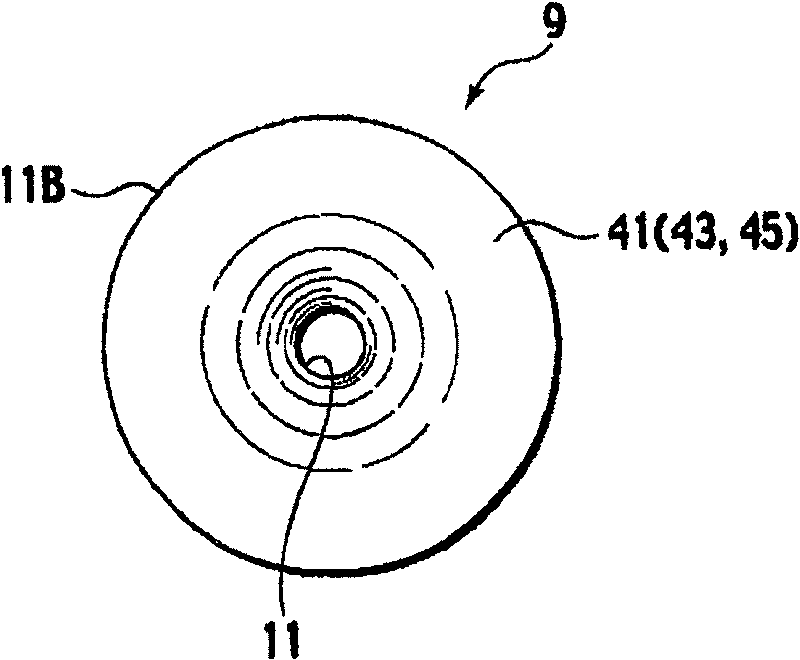

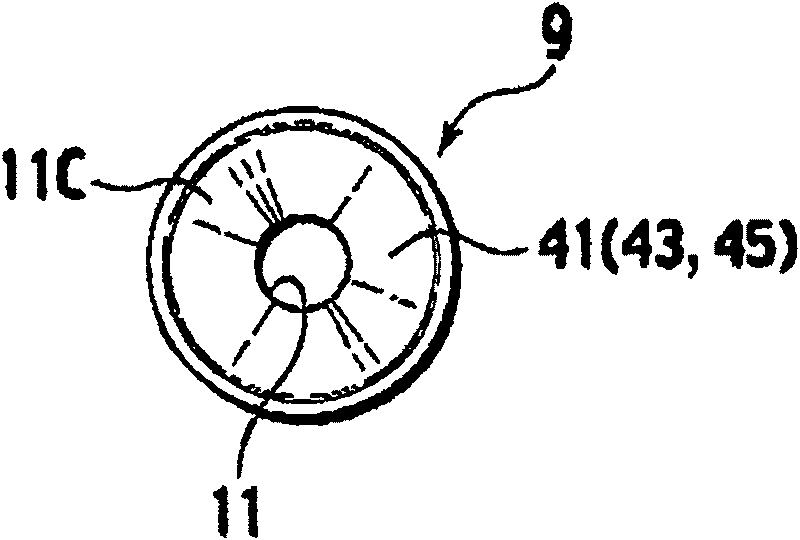

[0014] refer to image 3 , The spinning machine 1 is provided with a casing 3 that accommodates and supports the spinning nozzle 5 . further combined image 3 see figure 1 , from one side of the spinning nozzle 5 to the other, the long core yarn C1 and the long covering yarn E1 pass through the spinning nozzle 5 and are processed into a long yarn Y1 therein.

[0015] Yarn guides 17 and 19 are provided on the upper wall 3U of the housing 3 , through which the yarns C1 and E1 are introduced into the housing 3 . The housing 3 is further provided on its right wall 3R with yarn guides 23 and 25 for guiding the introduced yarns C1 and E1 to the spinning nozzle 5 . The housing 3 is further provided with a liquid nozzle 13 obliquely above the spinning nozzle 5 . The liquid nozzle 13 is provided with a liquid application portion 15 configured to apply a suitable...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com