Deep strengthening method of vacuum electroosmosis dewatering and low-energy dynamic compaction

An electro-osmotic dewatering, low-energy technology, used in the reinforcement of silt and silty soil foundations, the comprehensive reinforcement of large-area soft soil foundations, and the field of flowing mud, which can solve the problems of "rubber soil, small reinforcement depth, and rapid pressure dissipation." Slowness and other problems, to achieve the effect of shortening the consolidation time, expanding the depth of influence, and increasing energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

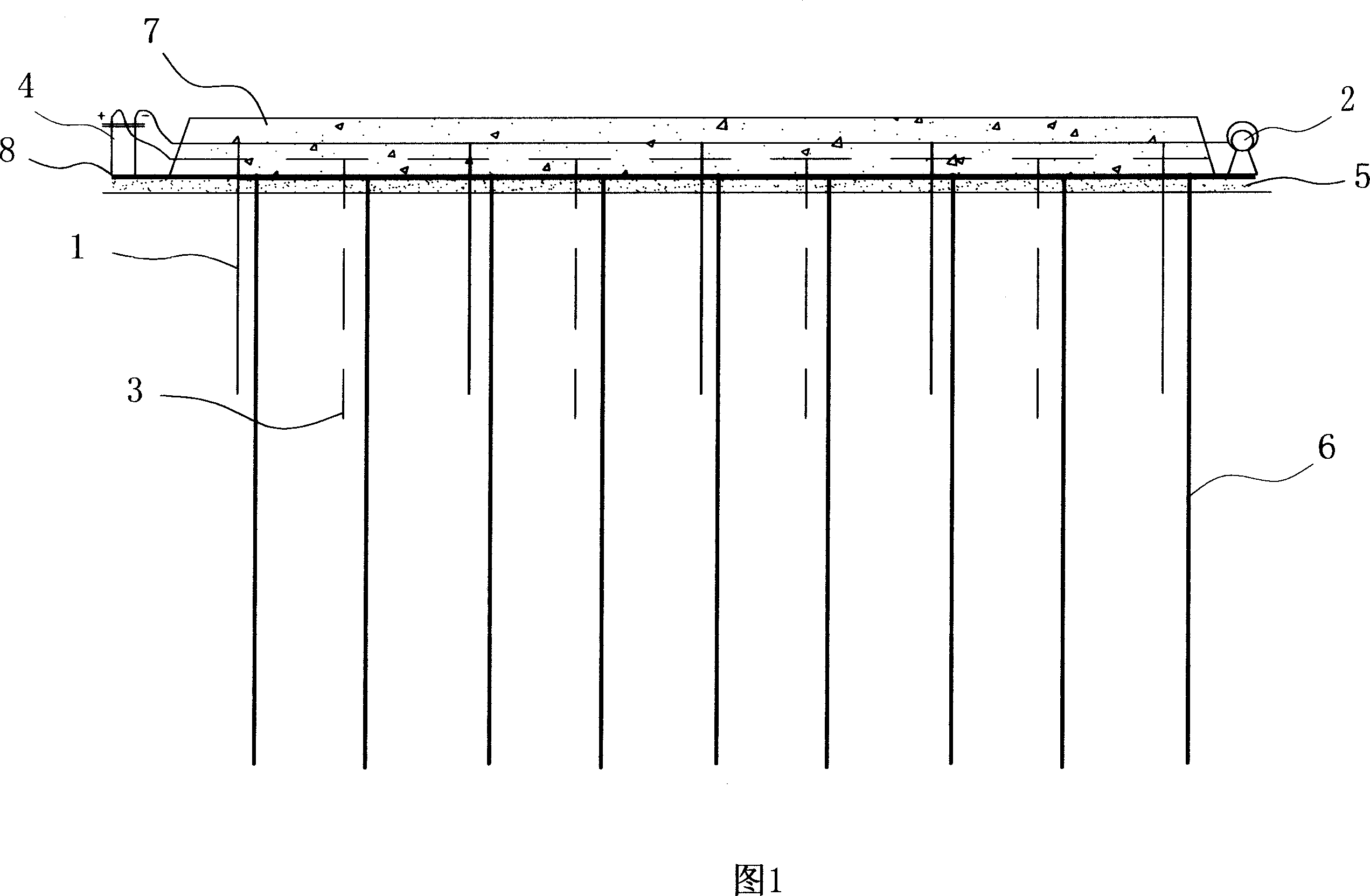

[0026] Embodiment 1: Referring to the accompanying drawing 1,

[0027] 1. After leveling the site, lay a medium-coarse sand cushion 5 of about 40 cm on the site, and the medium-coarse sand has a mud content of less than 3%;

[0028] 2. Insert plastic drainage boards 6 vertically on the sand cushion. The distance between plastic drainage boards is 0.8 to 1.4 meters. The reinforcement depth of plastic drainage boards is carried out according to the following principles: when the soft soil of the site is not too thick, the plastic boards should run through Soft soil; when the soft soil is deep and thick, the reinforcement depth should be determined by the allowable deformation value of the superstructure; then lay a clay layer 8 on the cushion and compact it.

[0029] 3. Arrange a vacuum well point dewatering system on the sand cushion layer to carry out vacuum well point dewatering: that is, vertically insert many rows of parallel cross well point pipes 1 on the sand cushion lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com