Detecting method for micro cantilever beam adhesion characteristics

A micro-cantilever beam and detection method technology, which is applied in the testing of machines/structural components, measuring devices, vibration testing, etc., can solve the problems that SEM cannot realize dynamic testing and cannot accurately judge the beam structure, and achieve good reliability and precision high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

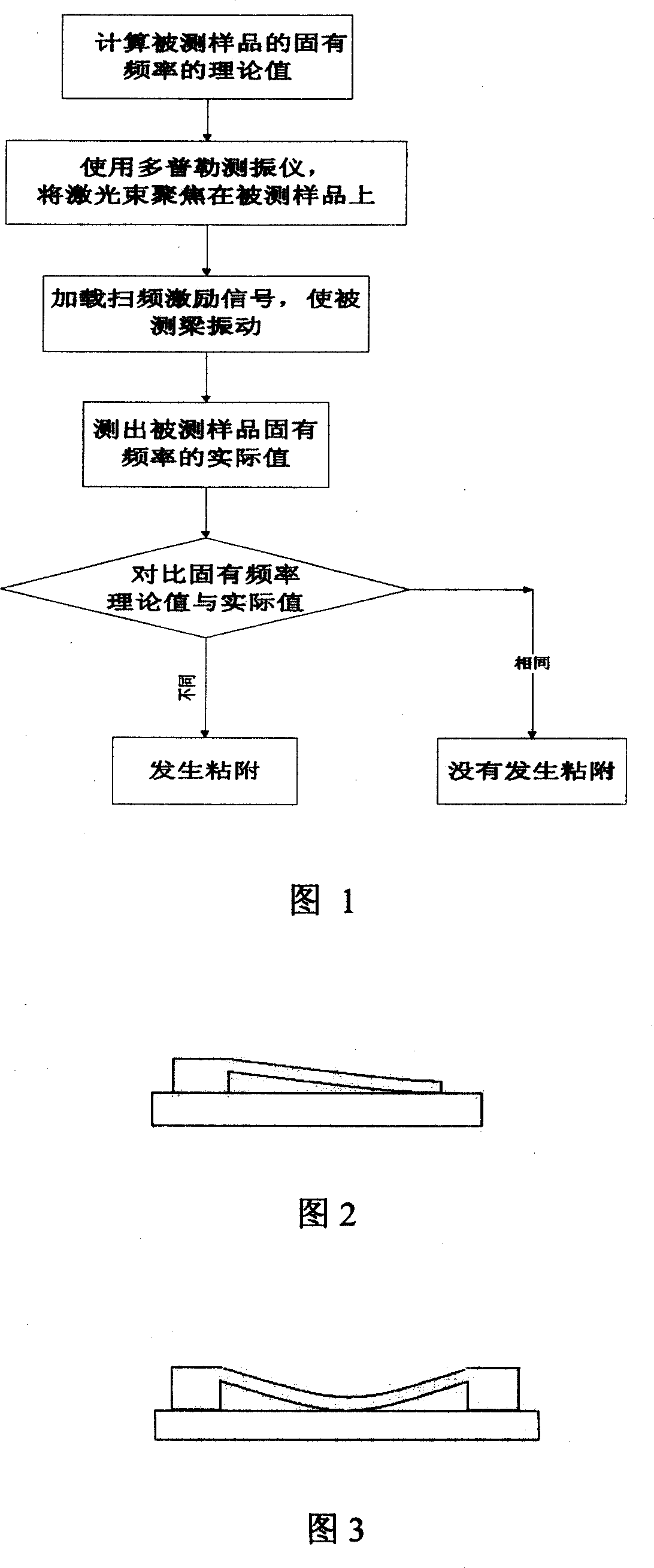

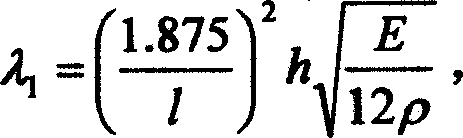

[0016] The present invention adopts the scheme as shown in the accompanying drawing to realize. The test system includes a Doppler vibrometer (Doppler) and a sample to be tested. The samples to be tested include cantilever beams and double-end fixed beam structures.

[0017] The specific implementation steps of the method are as follows: the sample to be tested is driven by a function generator of a Doppler instrument, the driving signal is loaded as a frequency sweep signal with a certain bandwidth, and the sample to be tested will vibrate after being powered on. The laser transmitter of the Doppler emits laser light, projects the laser beam on the beam structure to be tested, and recovers the laser signal reflected by the beam structure, and passes through the signal hardware and software of the Doppler With partial processing, the vibration of the beam can be observed on the monitor. The specific test process is:

[0018] For example, to measure the adhesion properties o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com