Distributed laser processing system

A laser processing and distributed technology, applied in laser welding equipment, metal processing equipment, optics, etc., can solve the problem of high configuration cost, achieve novel structure, significant economic and social effects, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

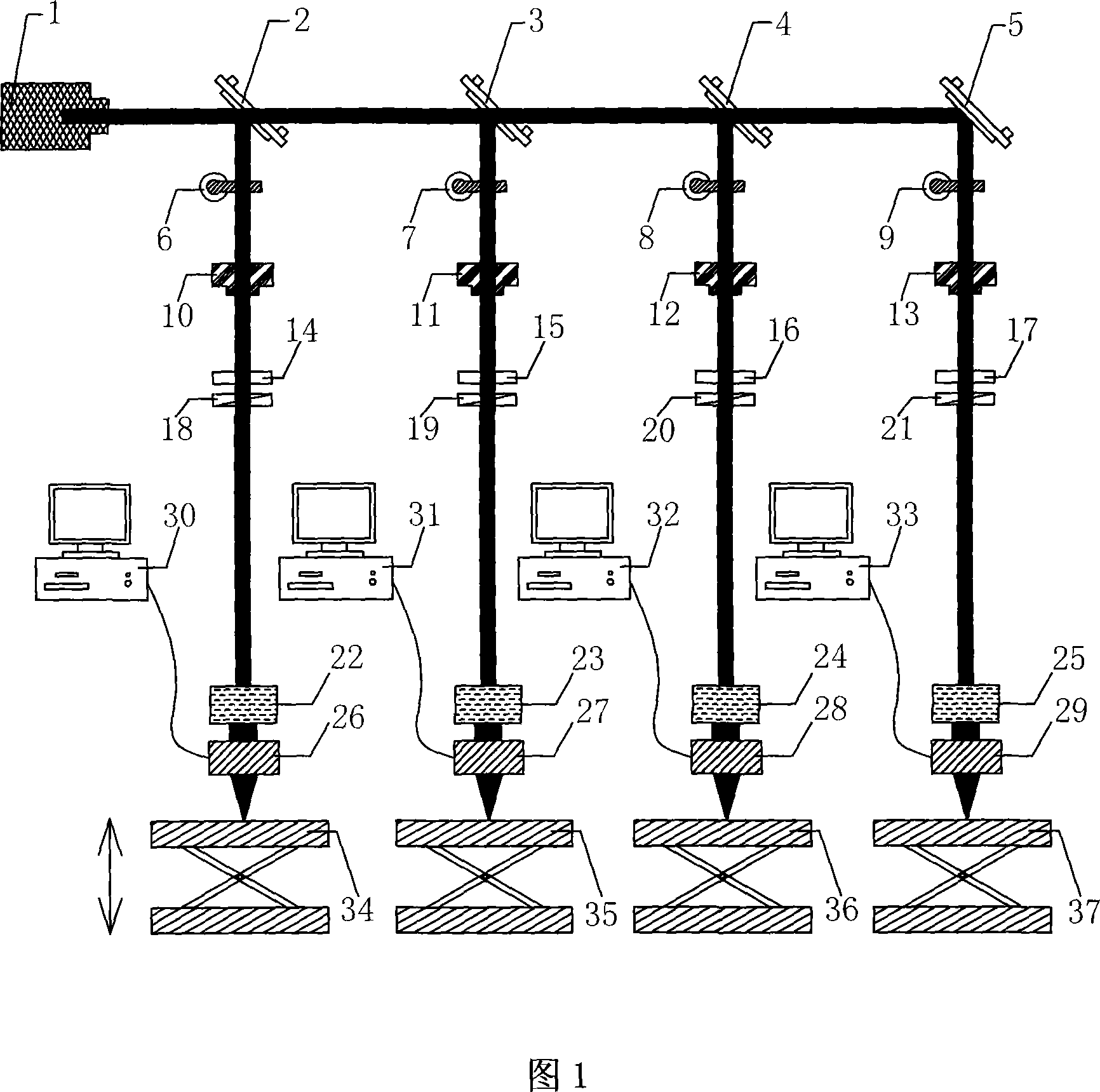

[0016] Distributed laser processing system, including: a laser, whose output power can meet the total power requirements of multiple laser processing operations; multiple beam splitters and a total reflection mirror, which can divide a single beam into multiple beams; the number and beam The frequency modulator with the same number of channels can modulate the pulse repetition frequency of each laser according to the needs; the rotatable half-wave plate whose number is consistent with the number of beam channels can continuously change the polarization direction of each laser; the number and the number of beam channels Consistent polarizers, each path of laser light passes through the polarizer, the component perpendicular to the polarization direction of the polarizer is absorbed, and the component parallel to the polarization direction of the polarizer is output; the number of beam shaping and focusing systems consistent with the number of beam paths can be Reshape and focus ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com