Pressure converting to force pressure sensor/transmitter

A pressure sensor and force sensor technology, which is applied in elastic deformation gauge-type fluid pressure measurement, instrument, and force measurement, can solve the problems of isolation medium temperature influence, complex manufacturing process, limited application scope, etc., to improve the application scope, The effect of good long-term stability and improved measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

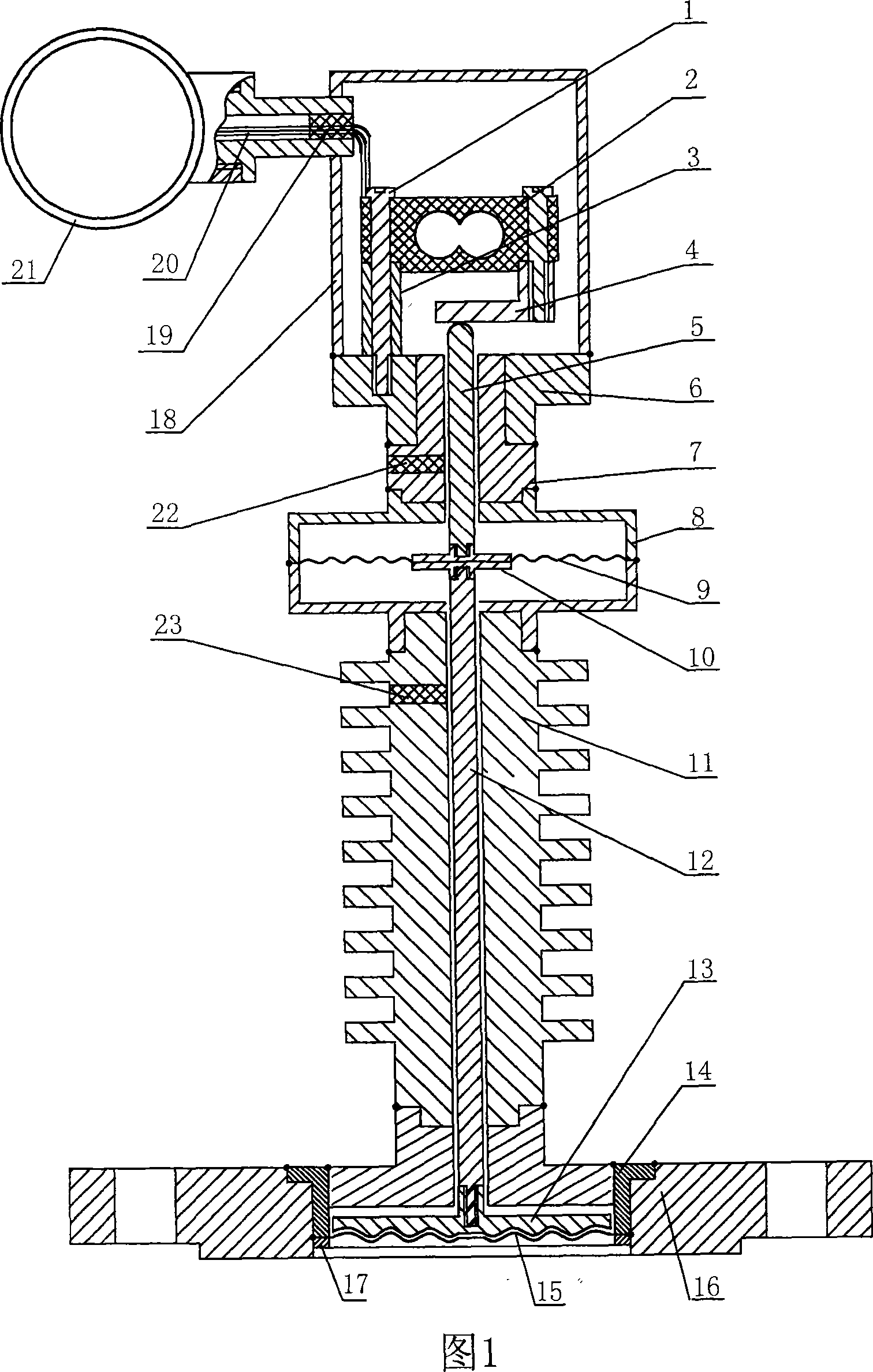

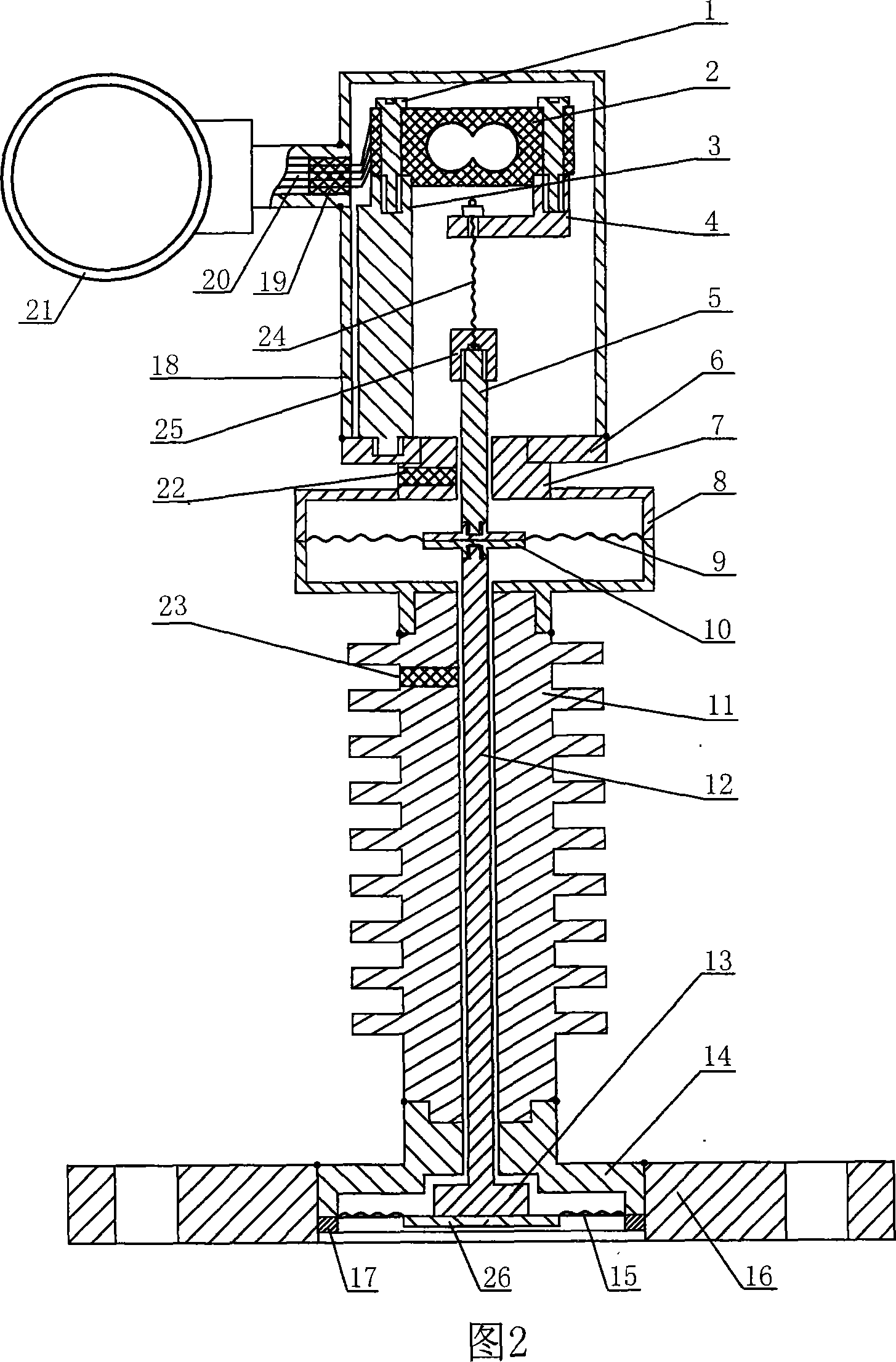

[0017]The specific structure and working process of the present invention will be described in detail according to Fig. 1-2. The device mainly adopts the commonly used force sensor with simple structure, easy manufacture, low cost, high precision and good long-term stability. The pressure is converted into force by the pressure guiding element to act on the force sensor to measure positive pressure (Fig. 1 The pressure sensor / transmitter of the type I structure shown in Figure 2 and the type II structure of measuring negative pressure (shown in Figure 2). The device includes a force sensor 2 fixed in the closed shell 18 of the base 6, a terminal box 21 connected by a lead wire 20 and a sealing plug 19, and a pressure guiding element assembled by connecting components. Among them, the force sensor 2 can adopt various types of commercially available force sensors, such as thick film sintered strain resistors of ceramic strain bodies, force sensors with laser trimmed resistance, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com