Optical thin sheet

A technology of optical flakes and photometers, applied in optics, optical components, nonlinear optics, etc., can solve the problems of increased weight, light absorption, inability to effectively use, waste of light sources, etc., and achieve good optical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

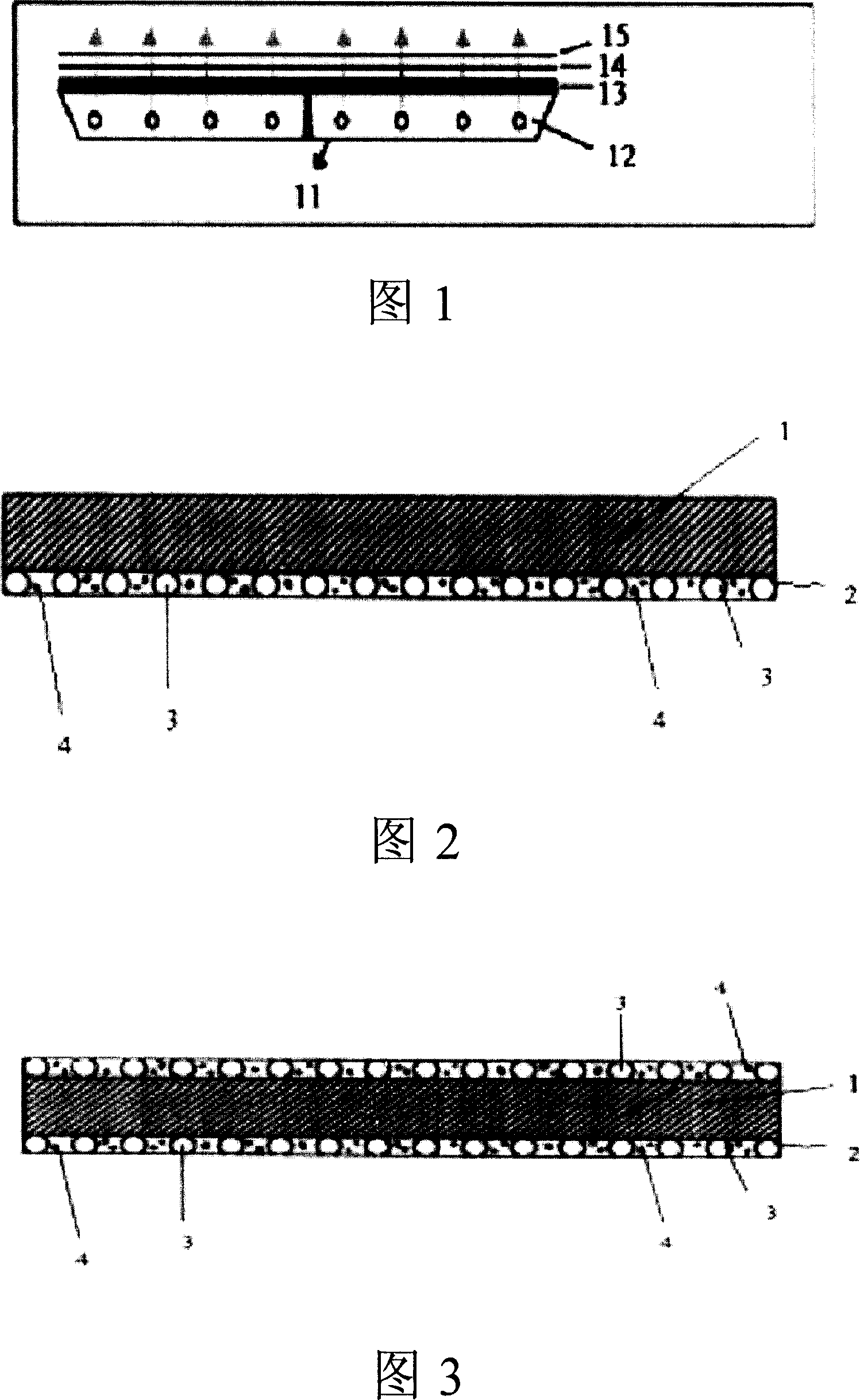

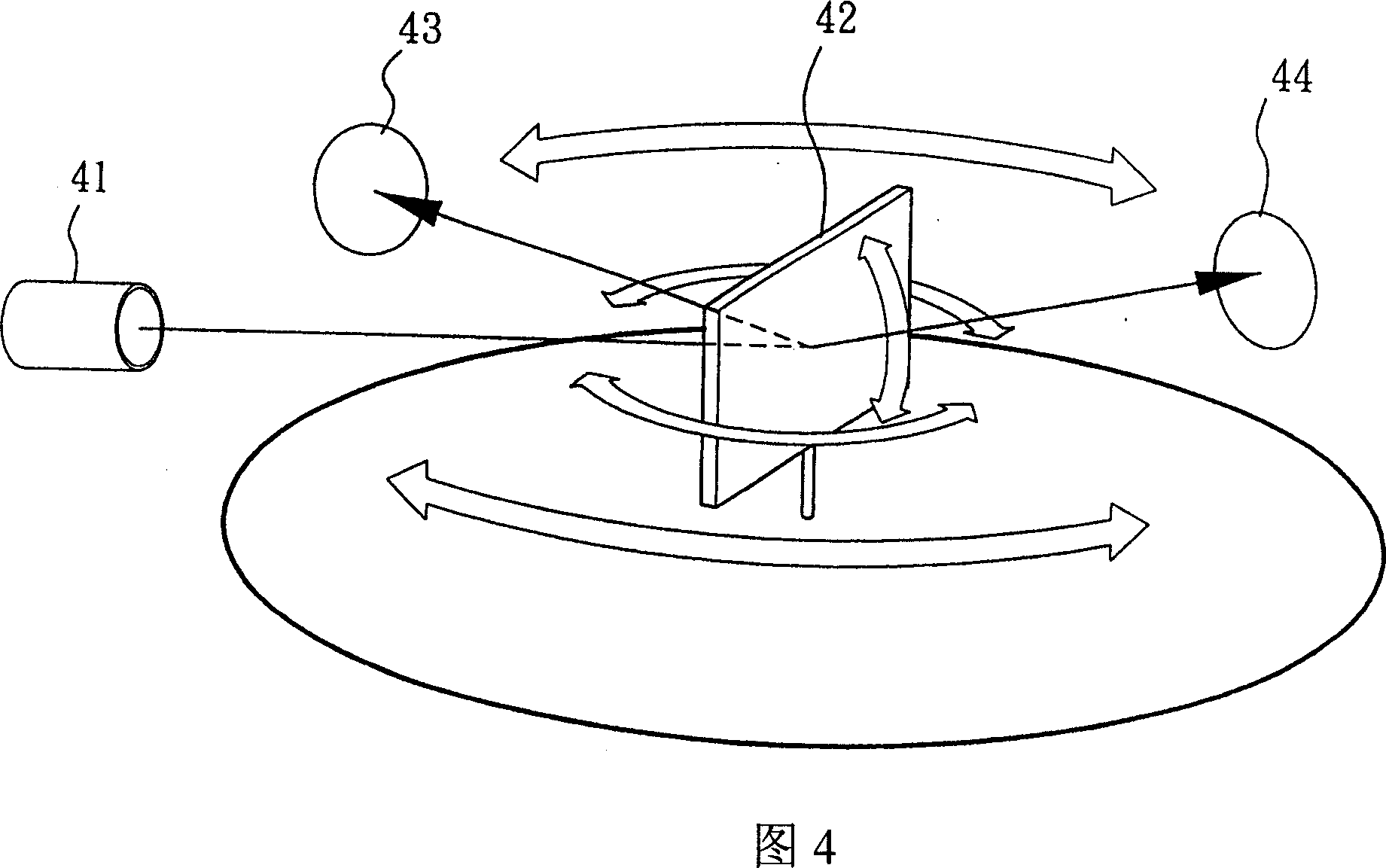

[0037] Embodiment 1 Optical sheet of the present invention

[0038] Add 21.0 grams of acrylic resin [Eterac 7363-ts-50, Eternal Company] (about 50% solid content) into a plastic bottle, then add methyl ethyl ketone and toluene each 38.0 grams of silicone with an average particle size of 2 μm under high-speed stirring Resin bead powder 32 grams [Tospearl 120E, GE Toshiba silicones company] and 1 ~ 100nm titanium dioxide, zirconium oxide, aluminum oxide, zinc oxide and tin oxide mixed suspension in ethyl acetate total 48 grams (solid content about 50%) , just add hardening agent [Desmodur 3390, Bayer company] 2.0 grams (about 75% of solid content) at last, soak and make about 35% of solid content, the about 171.0 gram coating of total weight. The paint was coated on both sides of the PET [T680E100, Mitsubishi company] substrate with RDS smear stick #12, and then dried at 120 ° C for 1 minute to manufacture a coating with a thickness of 10 μm on both sides of the substrate. Laye...

Embodiment 2

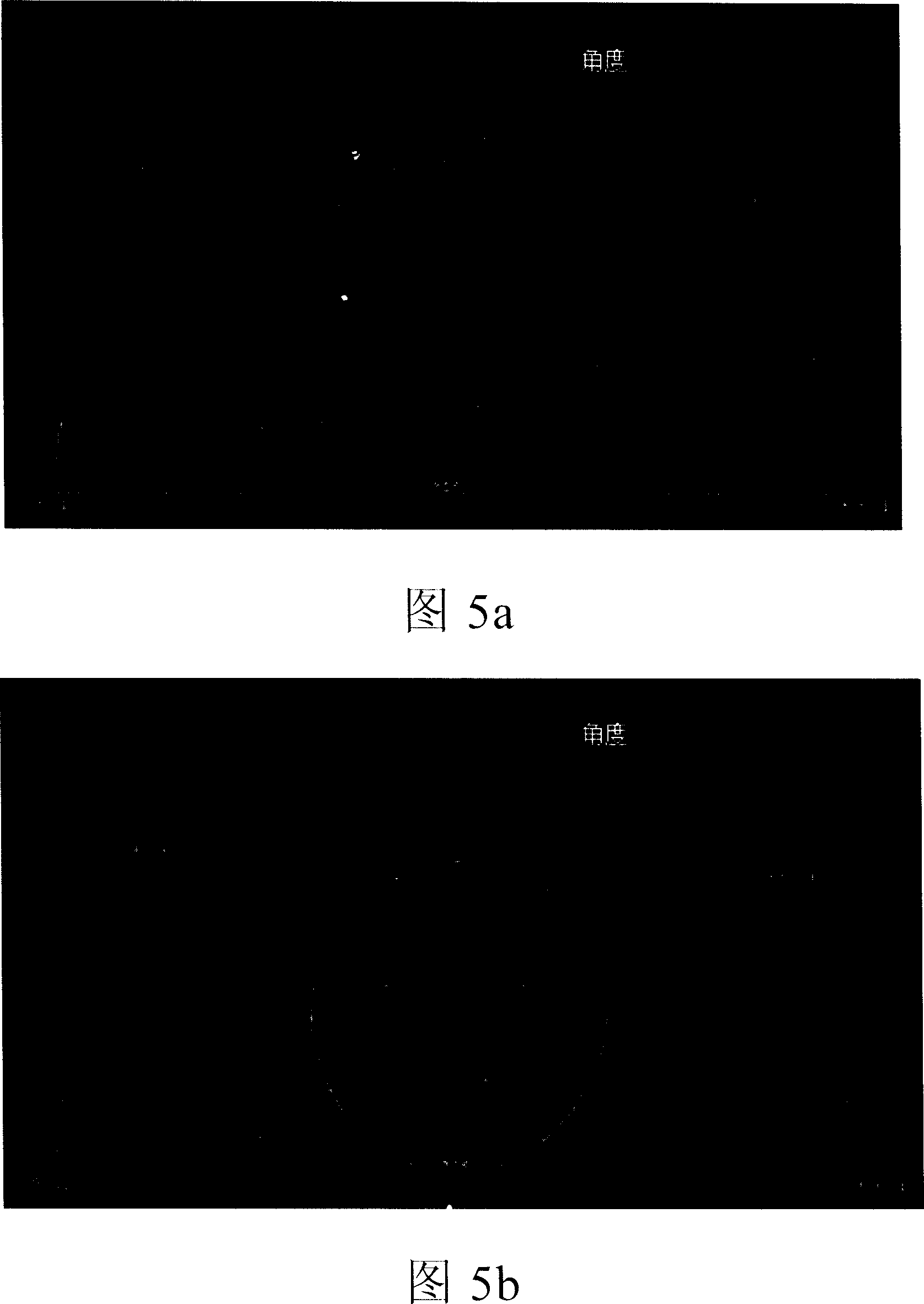

[0049] A photometric test was carried out on the optical sheet obtained in Example 1, and the test results are shown in Table 2 below and Figures 5a, 5b, 8a, and 8b.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com