Double-layer roll welding pipe welding process control system and control method thereof

A technology of double-layer coiled welded pipe and welding process, which is applied in the direction of general control system, control/regulation system, electrical program control, etc., and can solve problems such as difficult to realize the optimization of process parameters, difficult to guarantee the welding quality of welded pipe, and expensive imported equipment. , to achieve the effect of simple structure, improved welding quality and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

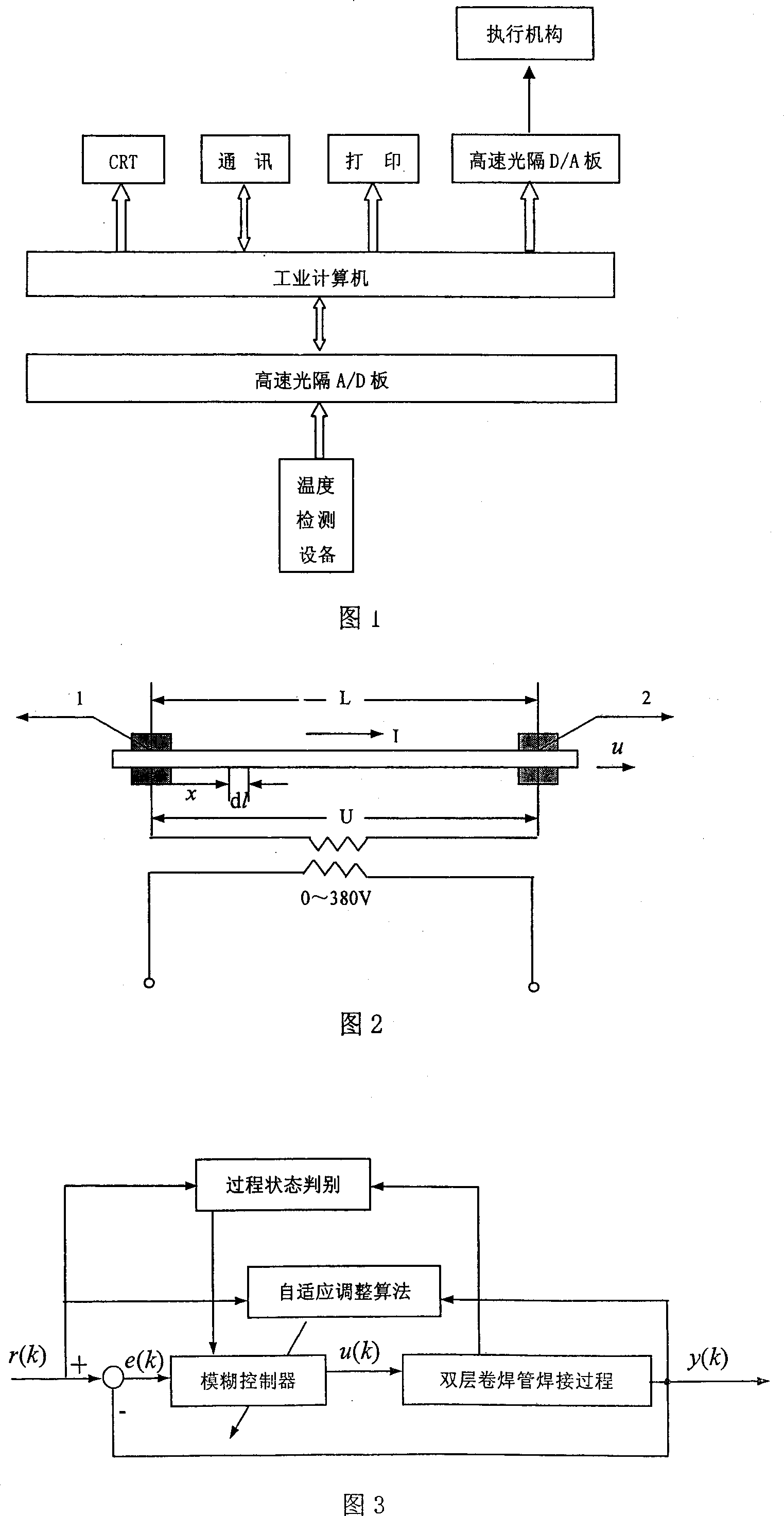

[0054] The embodiment of the control system of the present invention is shown in Fig. 1, and it is made up of temperature detection equipment, high-speed optical isolation A / D board, industrial computer and its peripheral equipment, high-speed optical isolation D / A board, executive mechanism; The output of temperature detection equipment The terminal is connected to the input end of the high-speed optical isolation A / D board. The high-speed optical isolation A / D board is connected to the industrial computer through the bus. The output end of the industrial computer is connected to the input end of the actuator through the high-speed optical isolation D / A board.

[0055] Described temperature detection equipment adopts optical fiber infrared colorimetric temperature measurement system (model is FR1B); 20-50cm away from the welded pipe.

[0056] The actuator adopts a thyristor voltage regulator.

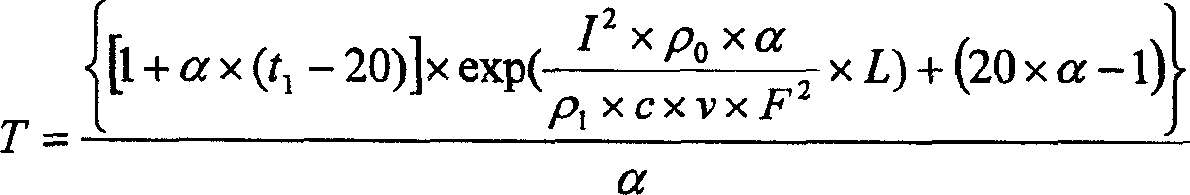

[0057] The embodiment of control method of the present invention comprises follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com