Oxidation-type disinfecting sterilizing agent and preparing method

A sterilizing agent and oxidizing technology, which is applied in the directions of disinfectants, botanical equipment and methods, biocides, etc., can solve the problems of short sterilization time, large surface tension and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

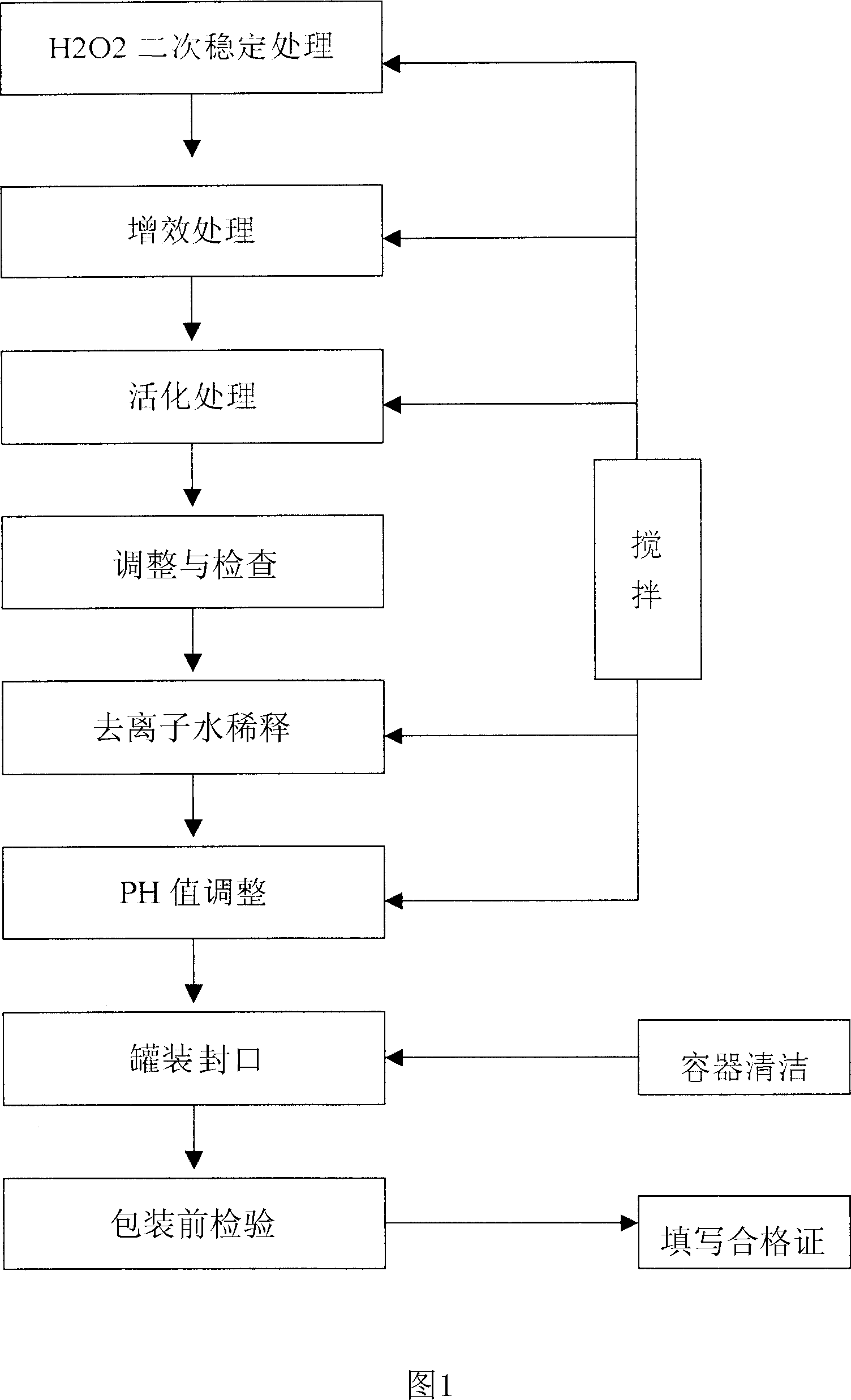

Image

Examples

Embodiment Construction

[0016] Below with the production of 100kg oxidant disinfectant as an example the present invention will be further described:

[0018] Silver Nitrate 1%

[0019] Sodium tripolyphosphate 0.3%

[0020] Phosphoric acid is about 2% (as a regulator to adjust the pH value to within 4.5),

[0021] Deionized water 86.7%;

[0022] Add 10% hydrogen peroxide to 1% silver nitrate to prepare an aqueous solution of a synergist to obtain a silver component with silver ions;

[0023] Add 0.3% of the stabilizer sodium tripolyphosphate to the above-mentioned silver component with silver ions and mix, then add 2% phosphoric acid to the above solution as an acid value regulator to adjust the pH value to within 4.5, and add 86.7% deionized water in time .

[0024] In the above preparation process, each obtained solution is slowly poured in while stirring at room temperature, prepared into an oxidized disinfectant, sealed in cans, inspected and packaged, and put ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com