Positioning dust-proof mechanism of ball screw-bar return-flow assembly

A ball screw and component technology, applied in mechanical equipment, belts/chains/gears, transmissions, etc., can solve the problems of not being able to fully press the return component 65, shaking the return component 65, and not having a perfect design, etc. Value, improved fixation, ease of manufacture and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

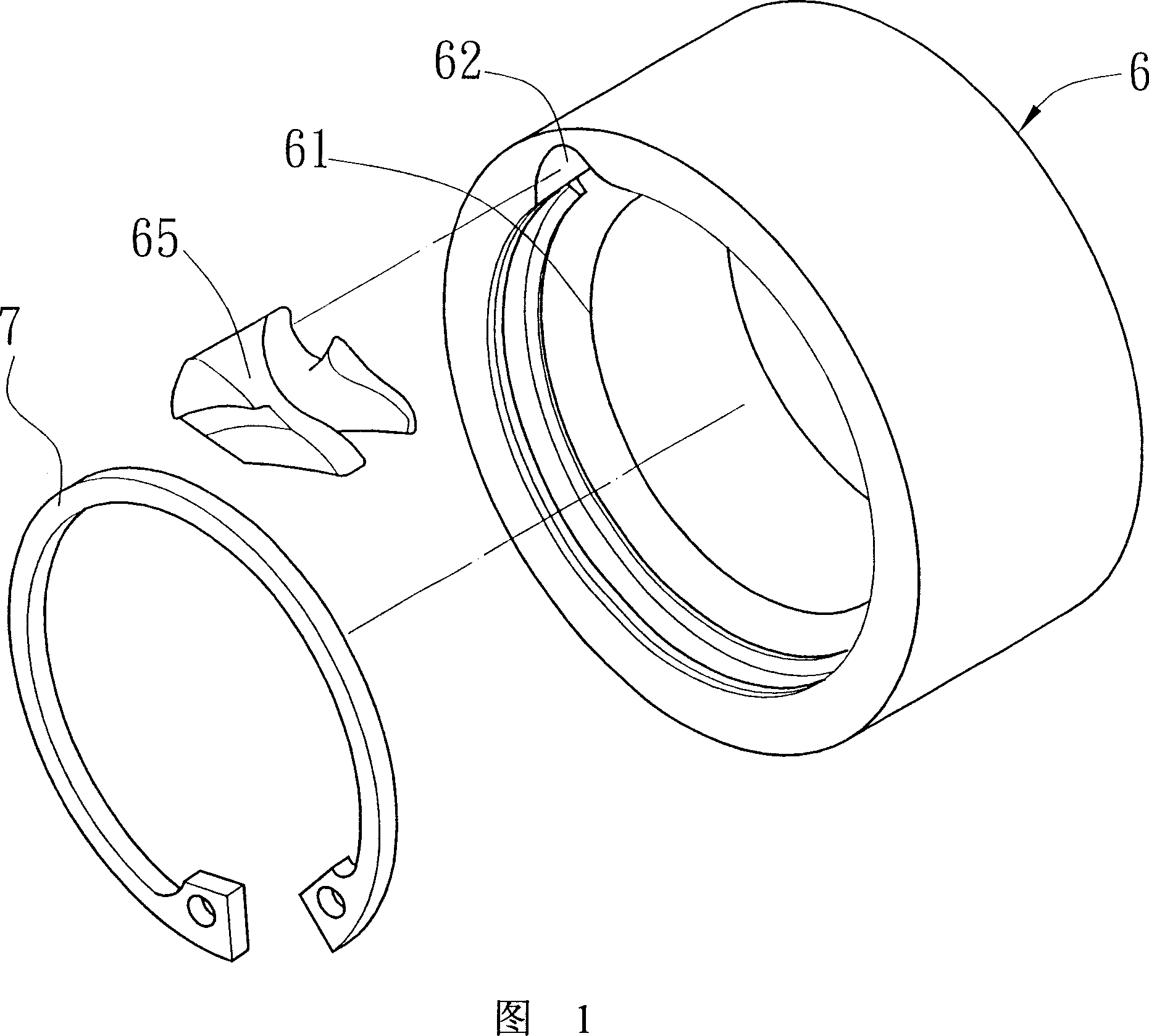

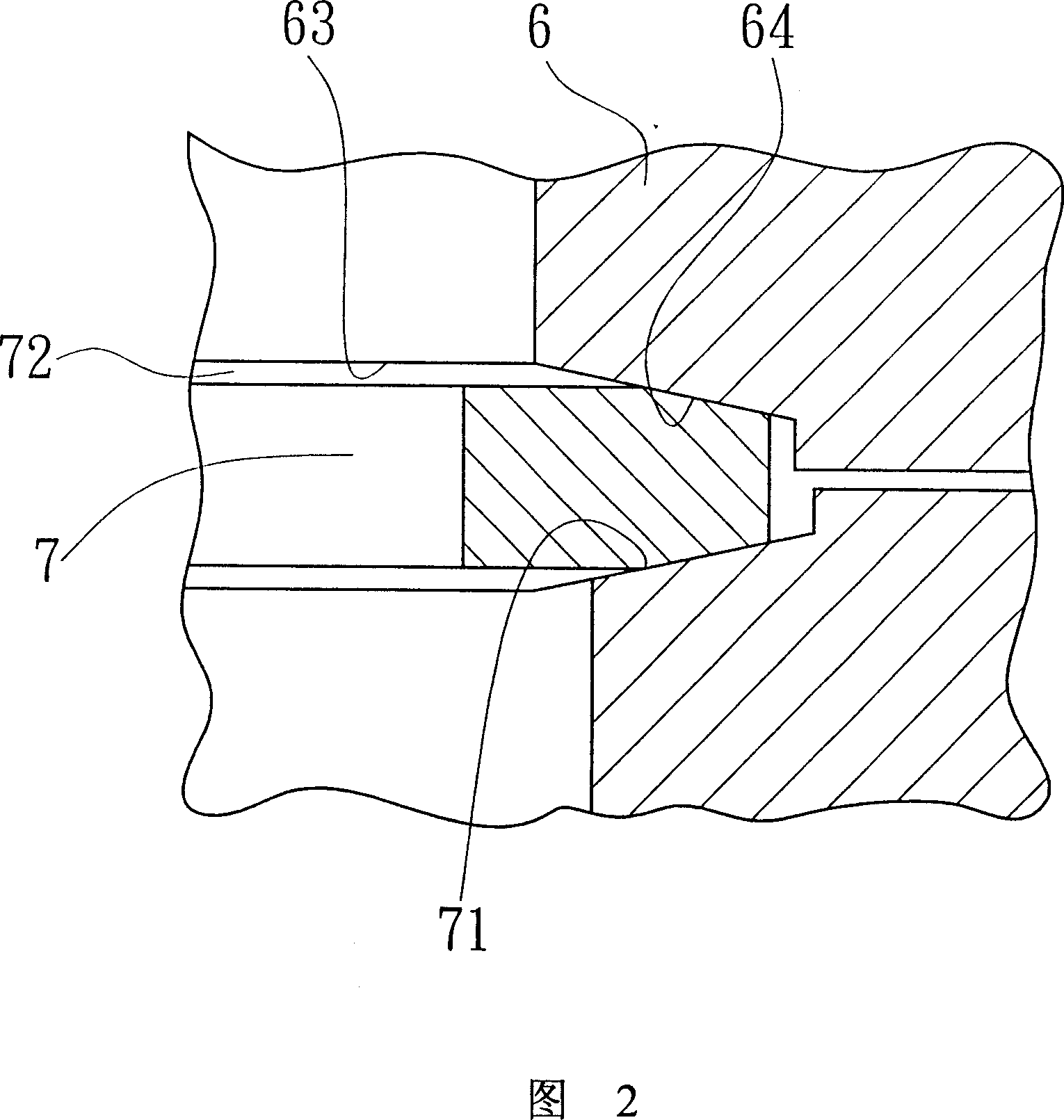

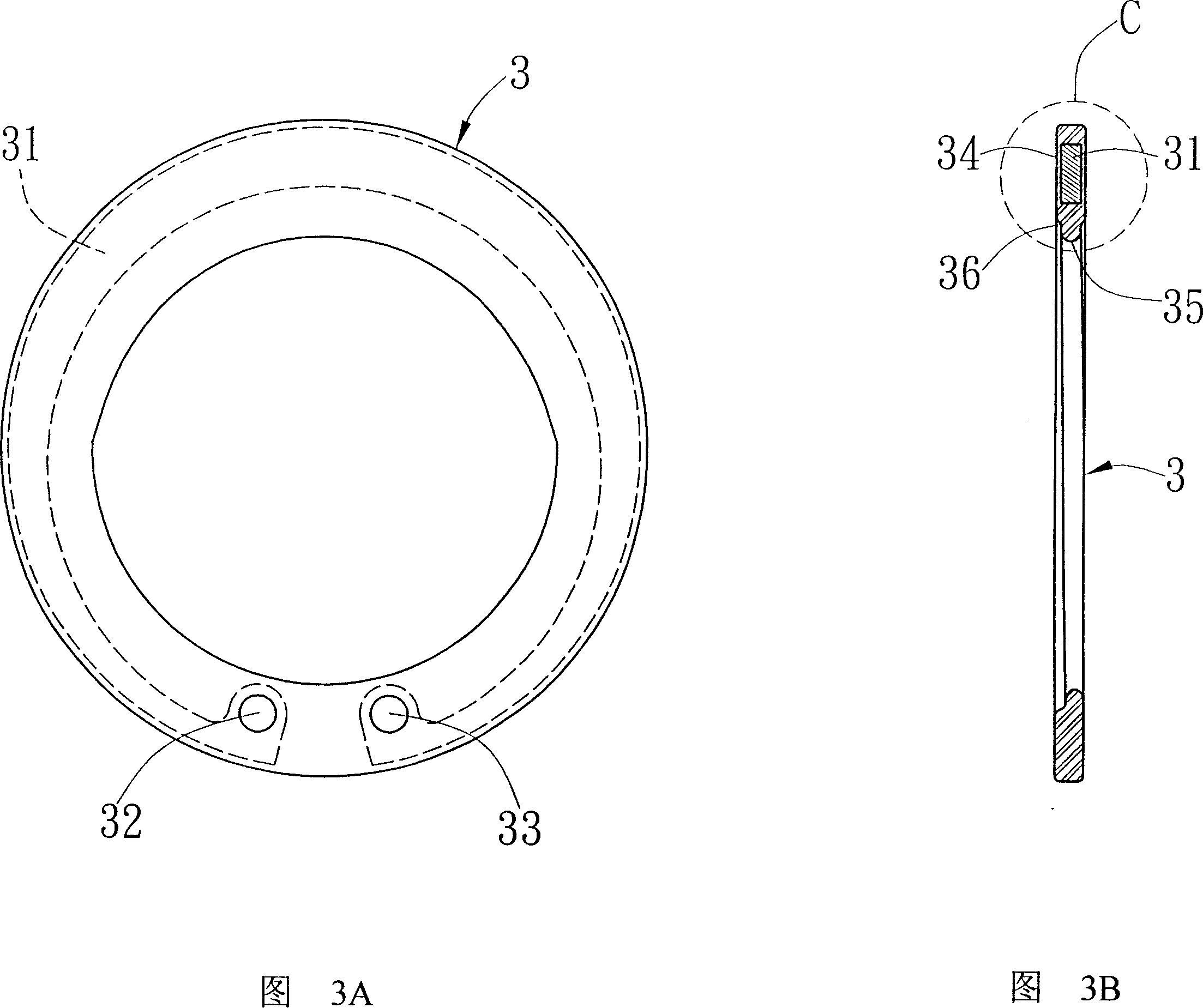

[0027] In order to explain the structure of the present invention and the effects achieved in detail, the following preferred embodiments are illustrated in conjunction with the accompanying drawings.

[0028] As shown in Figures 3A to 3C and Figures 4 and 5, the positioning and dust-proof mechanism of the ball screw return assembly provided by the present invention is mainly formed by forming a spiral rolling groove on the ball screw. A nut body 1 with an inner edge corresponding to the rolling screw groove 11 is sleeved, and the rolling screw groove 11 of the nut body 1 is respectively fixed with a return assembly 2 at both ends, for balls (not shown) in the ball screw and The rolling screw groove 11 of the nut body 1 rolls with the return assembly 2 to achieve the purpose of relatively sliding the ball screw and the nut body 1. The structure and operation principle described above are the same as the prior art, and are not of the present invention. The features are, so I won’t ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com