Centrifugal impeller and pump apparatus

A centrifugal and impeller technology is applied to centrifugal impellers and a pump equipment. The pump equipment field with such centrifugal impellers can solve the problems of reduced impeller performance, longer meridian length, and increased friction loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

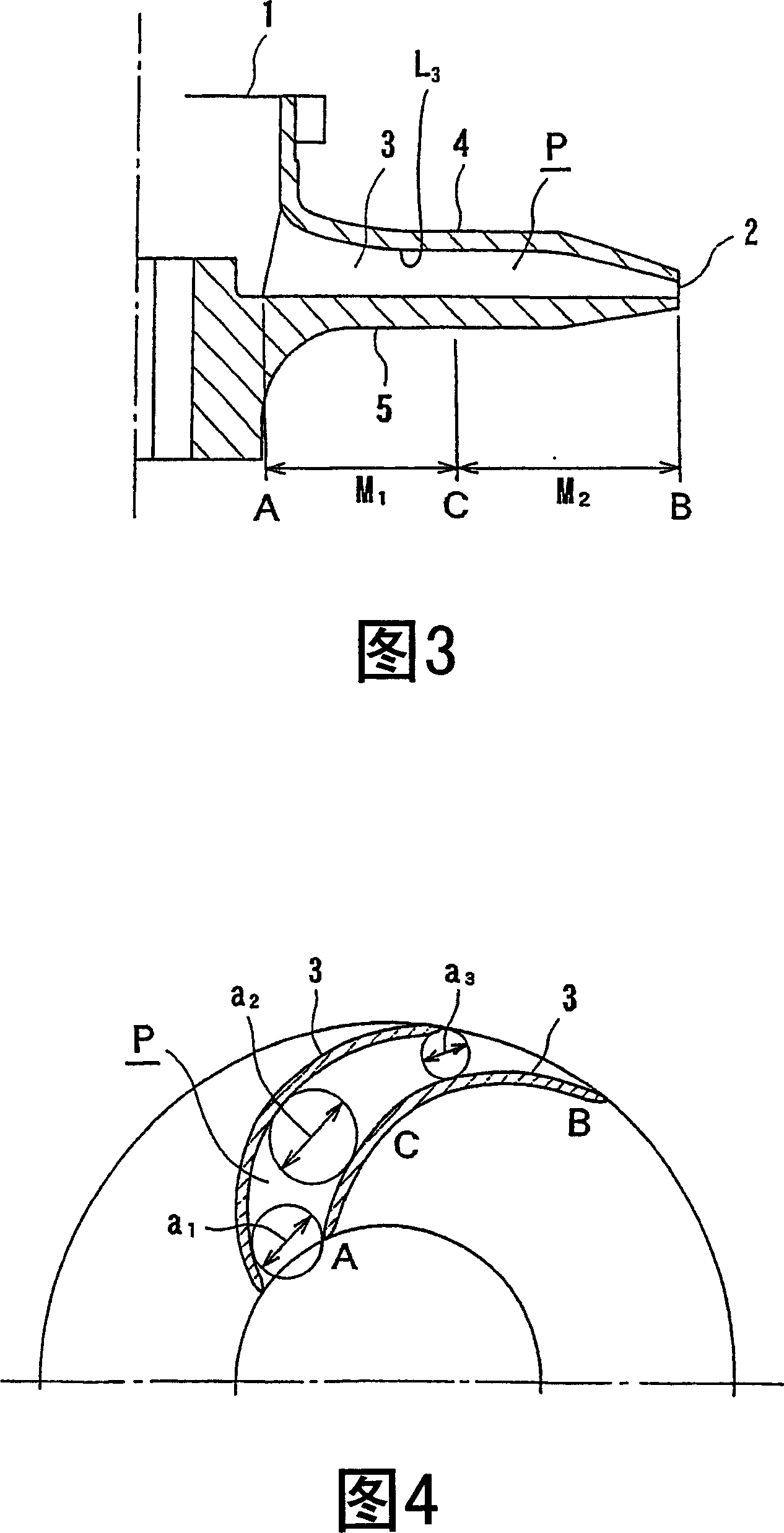

[0026] A centrifugal impeller according to one embodiment of the present invention will be described below with reference to the drawings. Fig. 3 is a meridian section view of the centrifugal impeller according to the first embodiment of the present invention, and Fig. 4 is a section view of the centrifugal impeller shown in Fig. 3 .

[0027] As shown in FIGS. 3 and 4 , the centrifugal impeller includes a plurality of blades 3 (only two adjacent blades 3 are shown in FIG. 4 ), a shroud (tip) 4 , and a hub 5 . The blade 3 is arranged between the wheel cover 4 and the hub 5 along the axial direction of the centrifugal impeller, and is arranged between the impeller inlet 1 on the central side of the centrifugal impeller and the impeller outlet 2 on the circumferential side of the centrifugal impeller. The blades 3 are angularly arranged at equal intervals on the circumferential direction of the centrifugal impeller and extend outward in a spiral manner. A plurality of flow paths...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com