Projection screen with holographic cylindrical lens structure

A cylindrical lens and projection screen technology, which is applied to a projection screen with a holographic cylindrical lens structure and its manufacturing field, can solve the problems of high cost, lack of good market application, and lack of industrialized products, and achieves low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

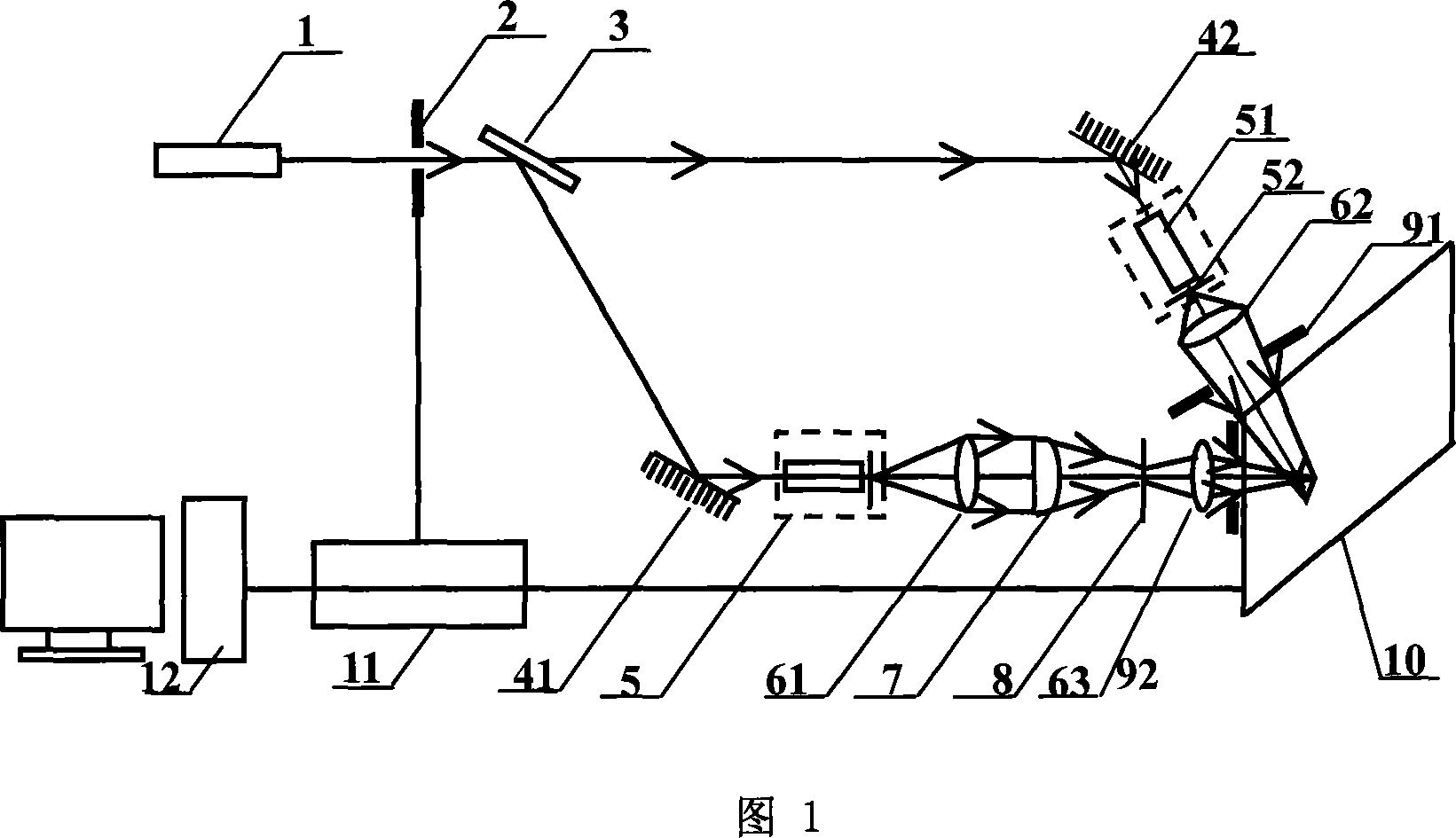

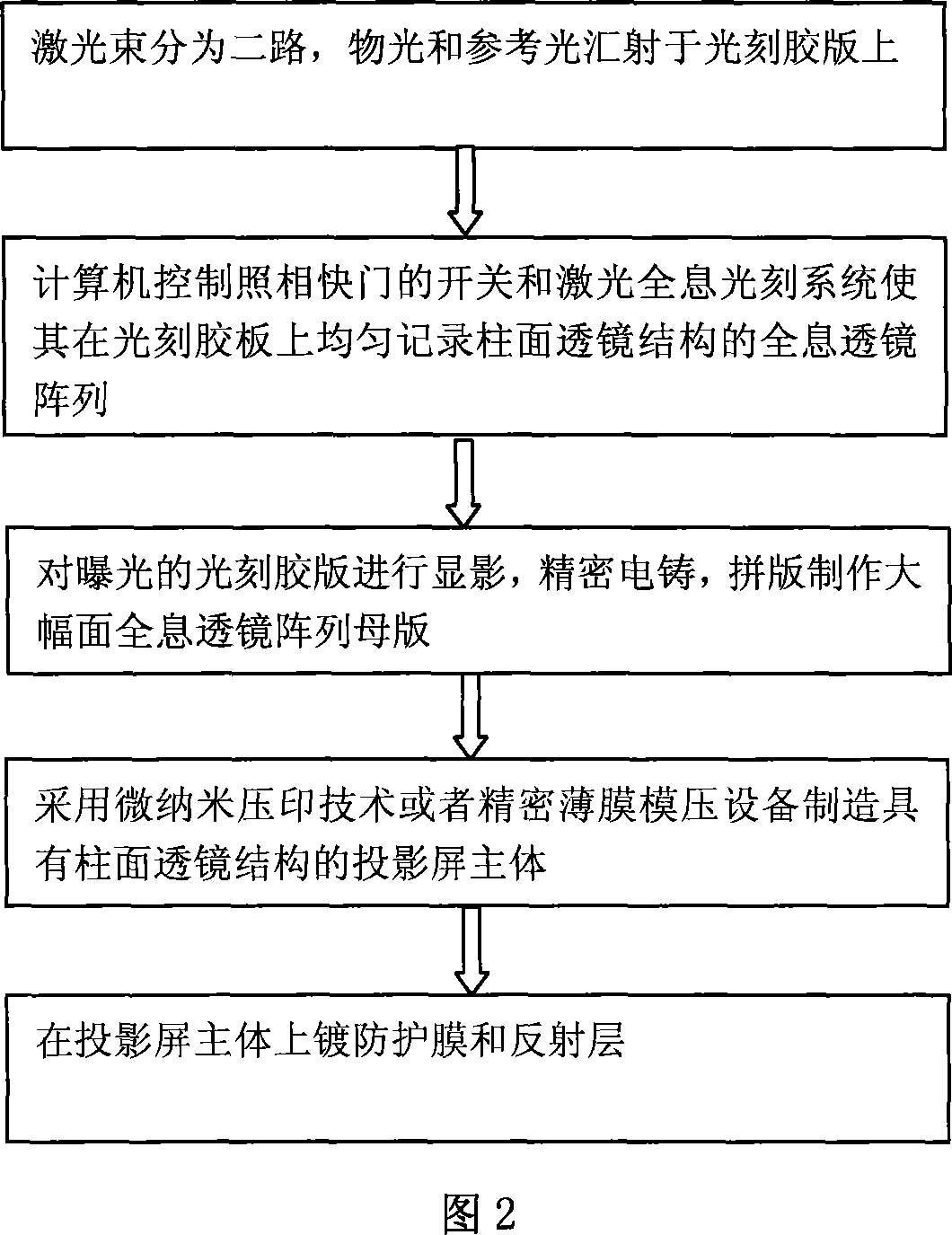

[0055] Referring to accompanying drawing 1, the production system of the present embodiment comprises: laser 1, photographic shutter 2, beam splitter 3, plane reflector 41,42, spatial filter 5 comprise beam expander 51 and pinhole 52, lens 61,62 , 63 , cylindrical mirror 7 , strip speckle screen 8 , apertures 91 , 92 , photoresist plate 10 , driver 11 and computer 12 .

[0056] The laser beam emitted by the laser 1 is divided into two paths by the beam splitter 3, one path passes through the lens 61 to form the object light, and the other path passes through the lens 62 as the reference light, and the object light and the reference light converge on the photoresist plate 10 at an included angle. Above, a spatial filter 5 is arranged in the optical path of the object light and the reference light, the spatial filter 5 includes a beam expander 51 and a pinhole 52, the beam expander 51 is placed at the front end of the pinhole 52, and the two spatial filters 5 Corresponding filte...

Embodiment 2

[0073] Embodiment 2: Ordinary projection screen of front projection type.

[0074] Referring to FIG. 7 , the composition structure of a normal front projection screen includes: a screen main body 13 , a holographic cylindrical lens array structure 14 , a Fresnel lens layer 15 , a high reflection layer 16 , and a diffuse reflection layer 17 .

[0075] Ordinary front-projection projection screens have a holographic cylindrical lens array pressed on one side of the main body of the screen, and a Fresnel lens layer is pressed on the other side of the surface using an adhesive or other methods known to those skilled in the art. Adhesive or other techniques known to those skilled in the art laminate a high reflective layer on the Fresnel lens layer, on the surface of the holographic cylindrical lens array by using adhesives or other methods known to those skilled in the art Press a diffuse reflective layer. The base layer of the holographic cylindrical lens array structure can be a...

Embodiment 3

[0076] Embodiment 3: Rear projection type ordinary projection screen.

[0077] Referring to FIG. 8 , the composition structure of a rear projection type common projection screen includes: a screen main body 13 , a holographic cylindrical lens array structure 14 , a Fresnel lens layer 15 , and a diffuse reflection layer 17 .

[0078] Rear-projection type ordinary projection screen, on one side of the screen main body, a holographic cylindrical lens array is pressed, and on the other side, a Fresnel lens layer is pressed with an adhesive or other methods known to those skilled in the art. A diffuse reflective layer is pressed on the surface of the holographic cylindrical lens array by using an adhesive or other methods conceivable by those skilled in the art. The base layer of the holographic cylindrical lens array structure can be a rigid or flexible transparent or translucent thin plate or film. However, the structure of the holographic cylindrical lens array structure layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com