Laser processing apparatus, laser processing head and laser processing method

A laser processing head and laser processing technology, applied in laser welding equipment, metal processing equipment, optics, etc., can solve the problems of difficult to remove waste, difficult to remove and discharge waste, redeposition, etc., to achieve the effect of reducing redeposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

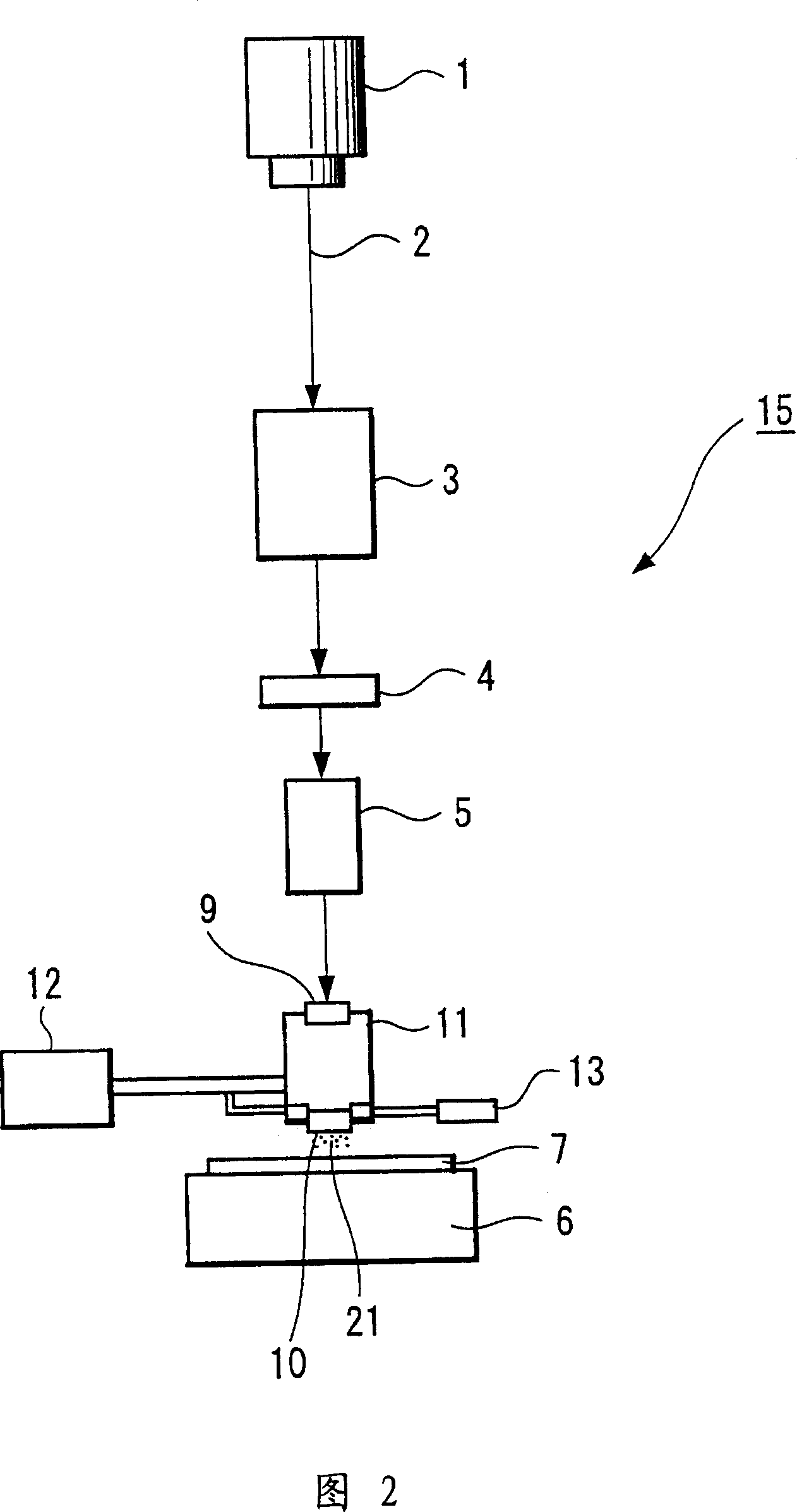

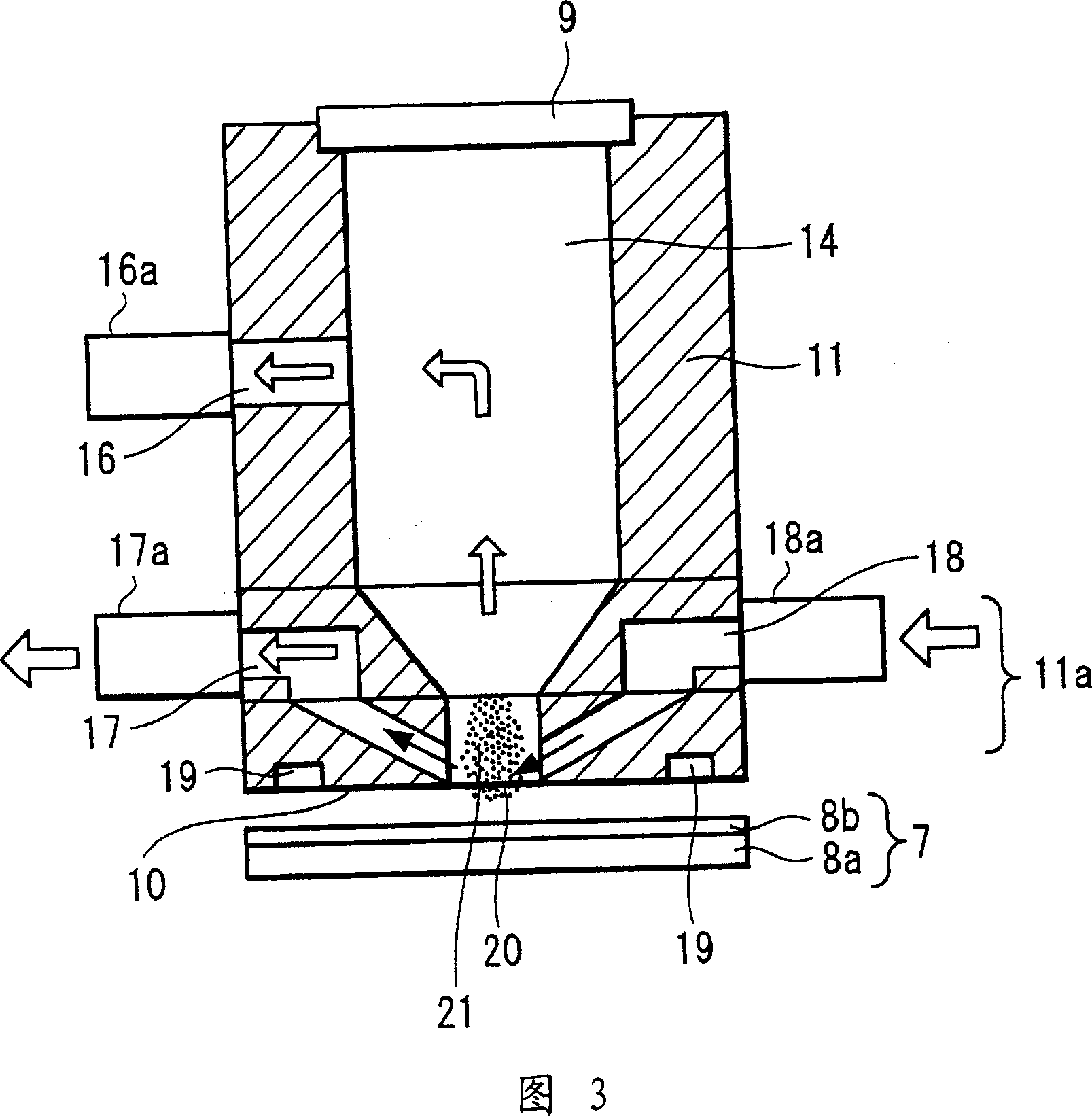

[0033] Hereinafter, the embodiment will be explained with reference to FIGS. 2 to 8 . A laser processing apparatus used in an embodiment includes a laser source, and an optical system that optically projects laser light emitted from the laser source in a predetermined pattern onto a processing surface of a processing object to perform ablation processing on the processing surface.

[0034] FIG. 2 is a diagram schematically showing an example of the configuration of a laser processing apparatus applied to the embodiment. The laser processing device 15 shown in Fig. 2 is configured to have a laser source 1, a beam shaper 3, a mask or an iris 4, a projection lens 5, a processing table 6, a decompression chamber 11 (laser processing head), An outlet portion 12 such as a roughing pump, and a gas inlet portion 13 . The laser processing device 15 performs ablation processing on the processing surface of the processing object 7 using the laser beam emitted by the laser source 1 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com