Lever balance head sheave long stroke pumping unit

A lever balance, long-stroke technology, applied to mechanical equipment, belts/chains/gears, mining fluids, etc., can solve problems such as poor transmission reliability, increased manufacturing costs, and complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

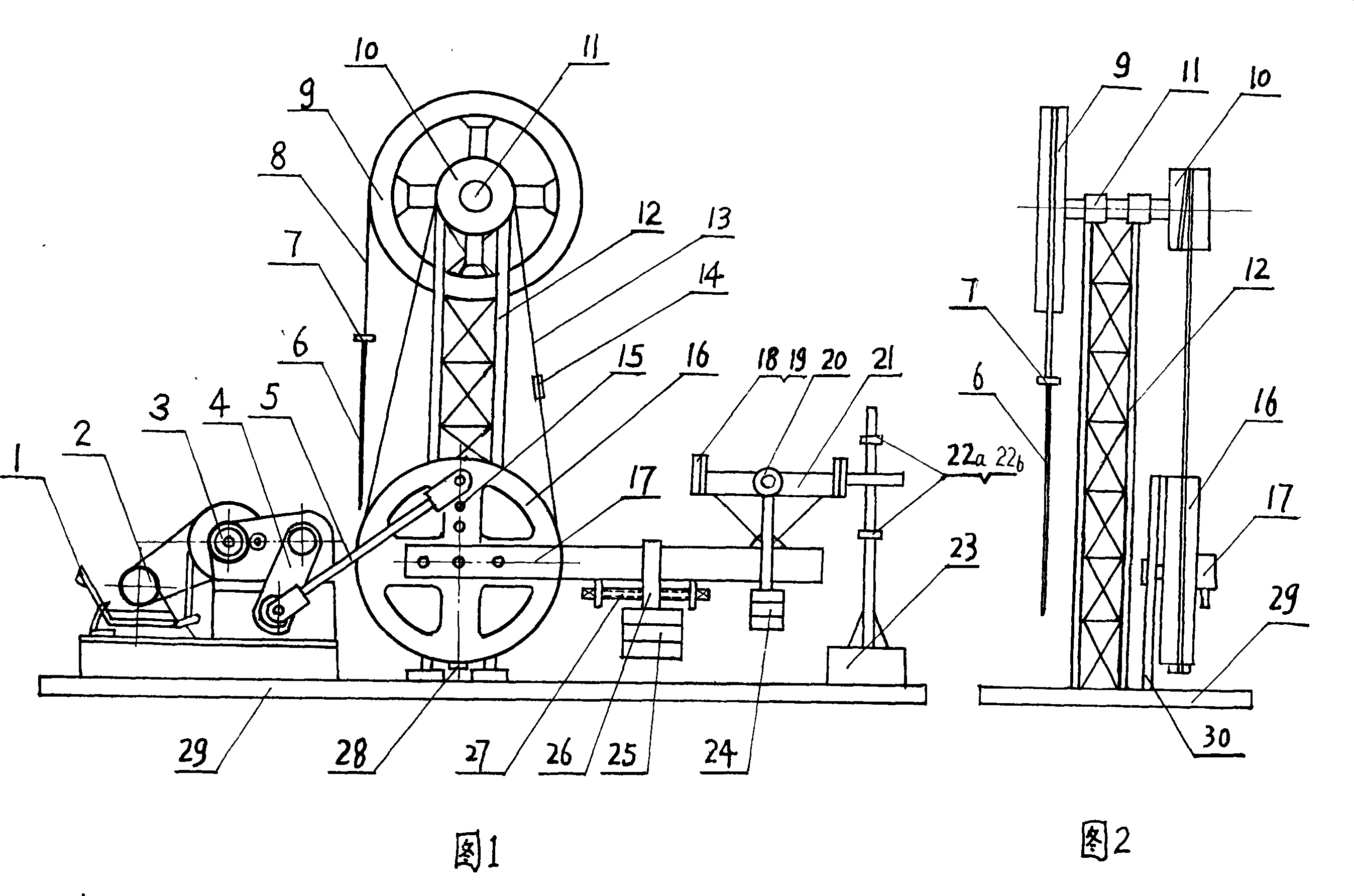

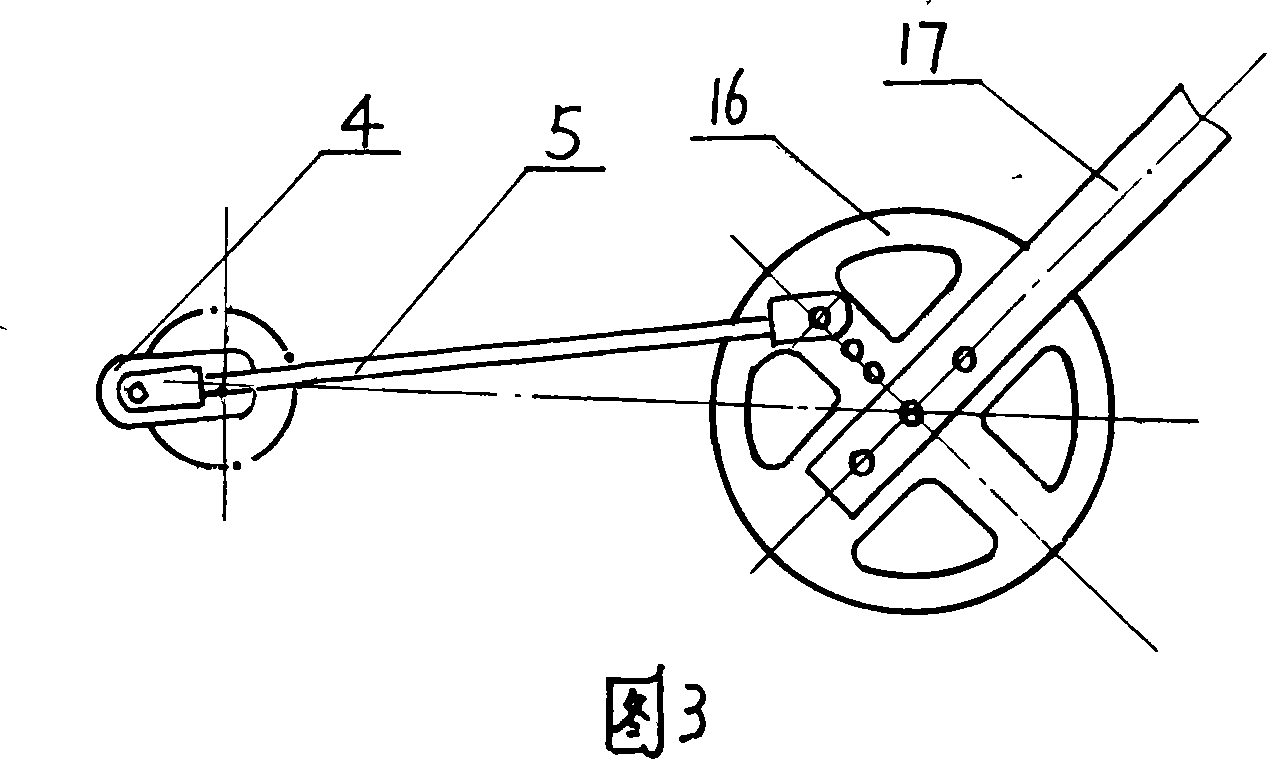

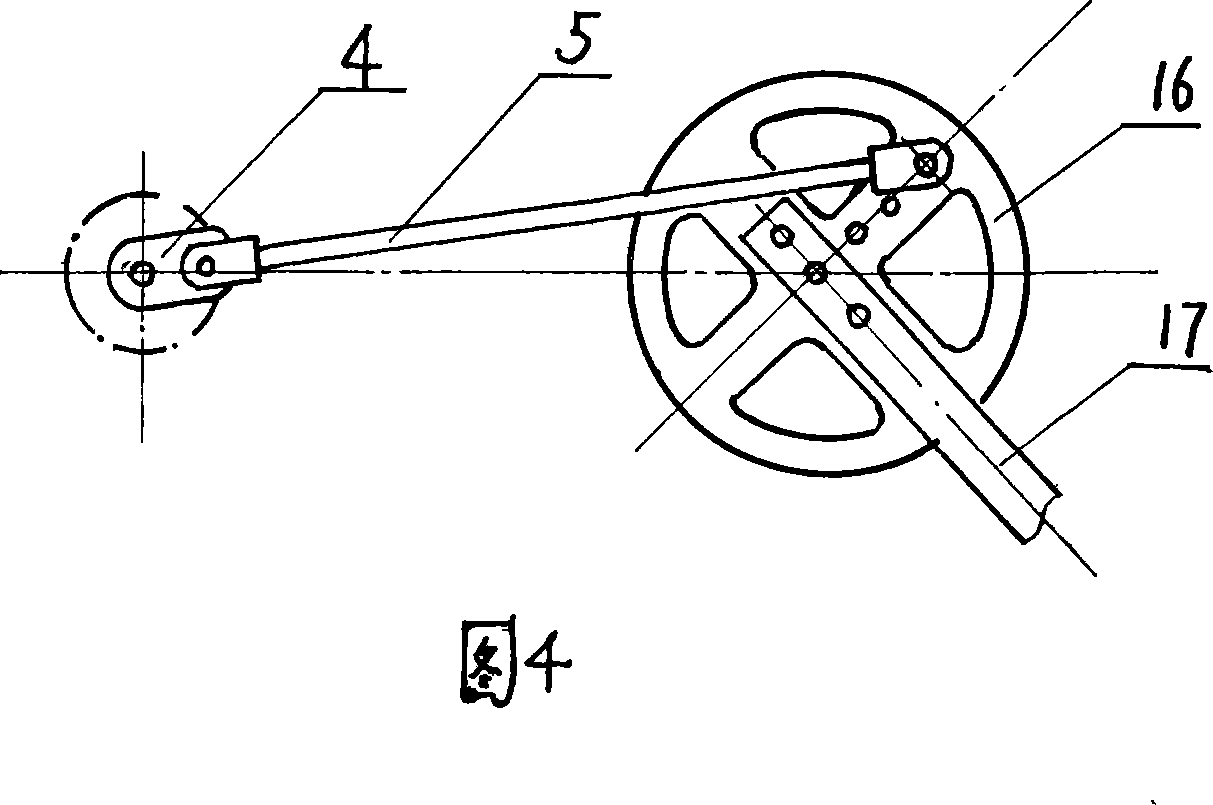

[0015] Referring to Figure 1 and Figure 2, the labels in the figure are: brake mechanism 1, motor 2, reducer 3, crank 4, connecting rod 5, sucker rod 6, rope hanger 7, suspension rope 8, sky wheel 9, Drive wheel 10, central wheel shaft 11, frame 12, steel wire rope 13, rope tightener 14, pin hole 15, drive reversing balance wheel 16, balance bar 17, limit baffle 18, elastic buffer pad 19, roller 20, Slide rail 21, upper limit block 22a, lower limit block 22b, limit bracket 23, auxiliary counterweight 24, counterweight 25, lifting rod 26, balance adjustment part 27, steel rope fixing part 28, base 29, support Seat 30.

[0016] The lever-balanced sky-wheel type long-stroke pumping unit of the present invention adopts a speed-regulating motor 2 for the power part, and is located on one side of the base 29 with the brake mechanism 1 and the speed reducer 3, and the connection and structure of each part still adopt the known technology. I will not repeat them here and there. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com