Making method for inorganic proton exchange film fuel cell film pole

A proton exchange membrane and fuel cell membrane technology, which is applied to fuel cell components, fuel cells, battery electrodes, etc., can solve the problem that the working temperature cannot exceed 200 °C, and achieve the effect of high heat dissipation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

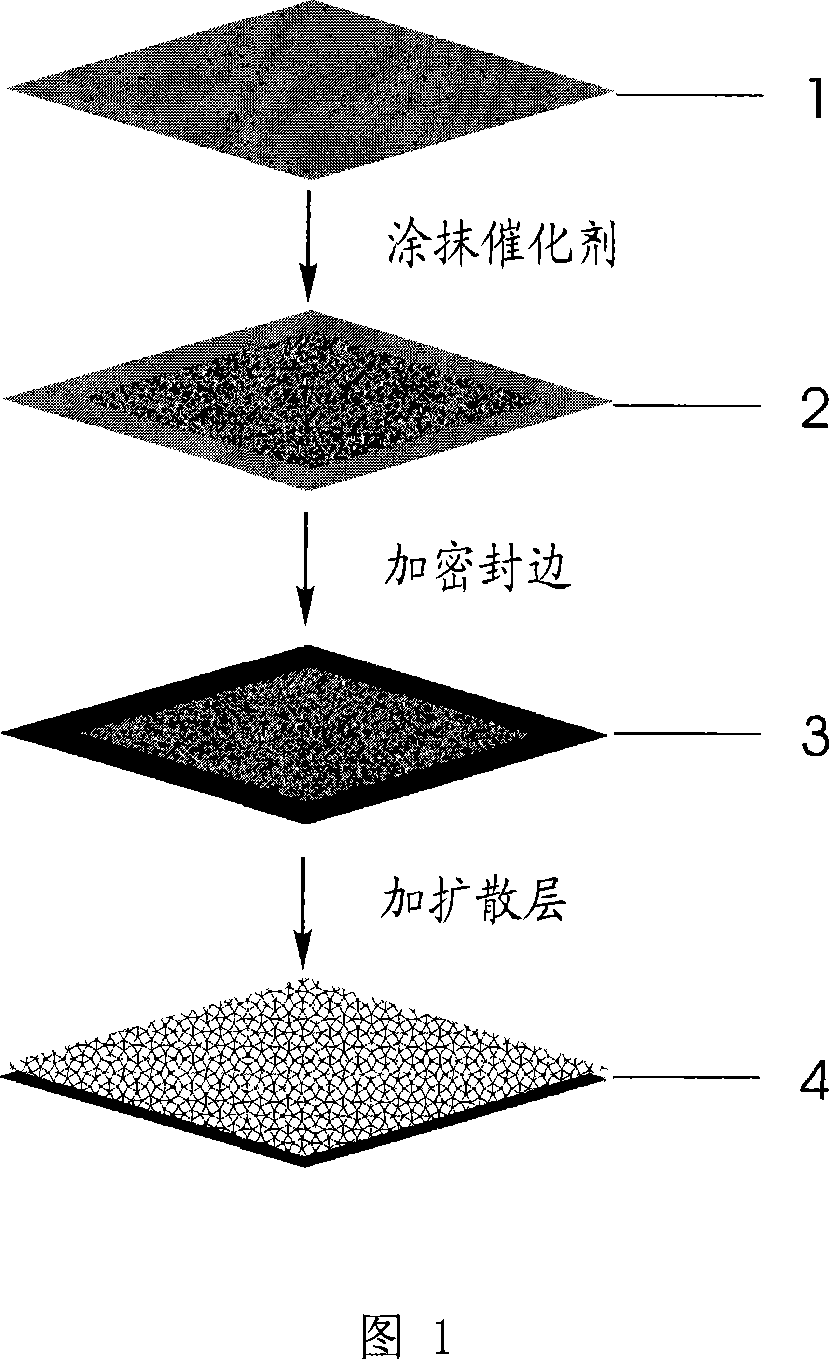

[0038] Embodiment 1: As shown in Figure 1,

[0039] 1. The preparation of inorganic proton exchange membrane is carried out according to the following steps:

[0040] 1) Weigh 20.8 grams of HPW (phosphotungstic acid) and 41.6 grams of ethyl orthosilicate, dissolve them in a mixed solvent composed of 50 grams of water and 500 grams of ethanol, and stir them electromagnetically for 15 minutes to obtain phosphotungstic acid and ethyl orthosilicate mixed solution of esters.

[0041] 2) Weigh 14 grams of surfactant P123, dissolve it in a mixed solvent composed of 50 grams of water and 500 grams of ethanol, and stir it electromagnetically for 15 minutes to obtain a solution of surfactant P123.

[0042] 3) Slowly add the surfactant P123 solution prepared in step 2) to the mixed solution of phosphotungstic acid and ethyl orthosilicate prepared in step 1), and stir at room temperature for 1 hour to prepare an inorganic proton conductive powder precursor .

[0043] 4) Put the inorgan...

Embodiment 2

[0048] 1. The preparation of inorganic proton exchange membrane, process is carried out according to the following steps:

[0049] 1) Weigh 4 grams of HPMo (phosphomolybdic acid) and 8 grams of tetraethoxysilane, dissolve in a mixed solvent of 50 grams of water and 150 grams of ethanol, and stir electromagnetically for 20 minutes to obtain phosphomolybdic acid and tetraethoxysilane Silane mixed solution.

[0050] 2) Weigh 4 grams of surfactant PMAA, dissolve it in a mixed solvent composed of 50 grams of water and 150 grams of ethanol, and stir it electromagnetically for 20 minutes to obtain a solution of surfactant PMAA.

[0051] 3) The surfactant PMAA solution prepared in step 2) was slowly added to the mixed solution of phosphomolybdic acid and tetraethoxysilane prepared in step 1), and stirred at room temperature for 1 hour to prepare an inorganic proton conductive powder precursor.

[0052] 4) Put the inorganic proton conduction powder precursor prepared in step 3) in a p...

Embodiment 3

[0057] 1. The preparation of inorganic proton exchange membrane, process is carried out according to the following steps:

[0058] 1) Weigh 1 gram of HSiW (silicotungstic acid) and 10 grams of ethyl titanate, dissolve them in a mixed solvent consisting of 50 grams of water and 250 grams of ethanol, and stir them electromagnetically for 30 minutes to obtain a mixture of silicotungstic acid and ethyl titanate solution.

[0059] 2) Weigh 10 grams of surfactant PEG, dissolve it in a mixed solvent composed of 50 grams of water and 250 grams of ethanol, and stir it electromagnetically for 30 minutes to obtain a surfactant PEG solution.

[0060] 3) Slowly add the surfactant PEG solution prepared in step 2) into the mixed solution of silicotungstic acid and ethyl titanate prepared in step 1), and stir at room temperature for 2 hours to prepare an inorganic proton conductive powder precursor.

[0061]4) placing the inorganic proton-conducting powder precursor prepared in step 3) in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com