Method for preparation of anhydrous magnesium chloride

A technology of anhydrous magnesium chloride and hydrogen chloride, applied in the direction of magnesium chloride, magnesium halide, etc., can solve the problems of short time, large-scale production cost, and low dehydration temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

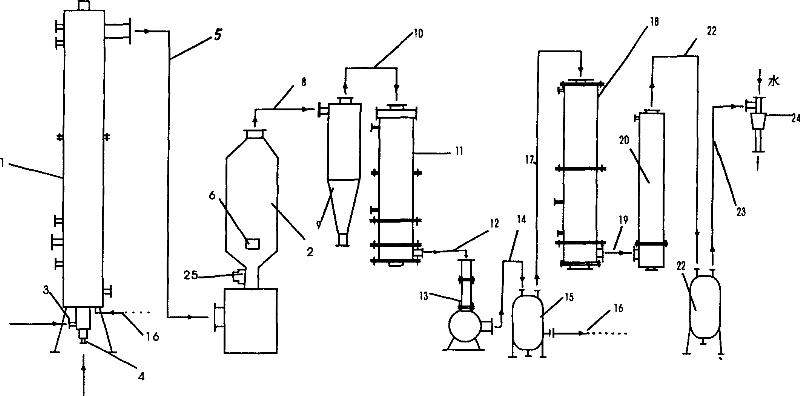

Image

Examples

Embodiment Construction

[0018] Hydrated magnesium chloride (MgCl 2 2H 2 O) The fine powder (50μm-1000μm) is sent into the pyrolysis reactor to control the relevant conditions.

[0019] The temperature of the hydrogen chloride synthesis furnace is greater than 600°C, adjust the synthesis amount of HCl gas so that the temperature at the top of the pyrolysis reactor is 338°C, and the pressure at the top of the pyrolysis reactor is controlled at 0-1000mmH 2 O.

[0020] The obtained result of above-mentioned embodiment is as follows:

[0021] 1. The pyrolysis rate of low-water magnesium chloride is greater than 98%

[0022] 2. The content of anhydrous magnesium chloride is greater than 92%

[0023] 3. Hydrochloric acid concentration 31-36%

[0024] 4. There is no gas leakage and no pollutant discharge during the system and production process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com