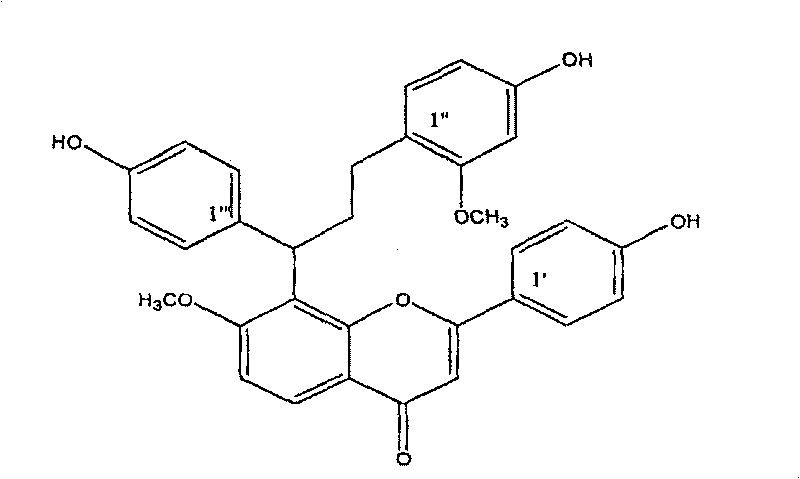

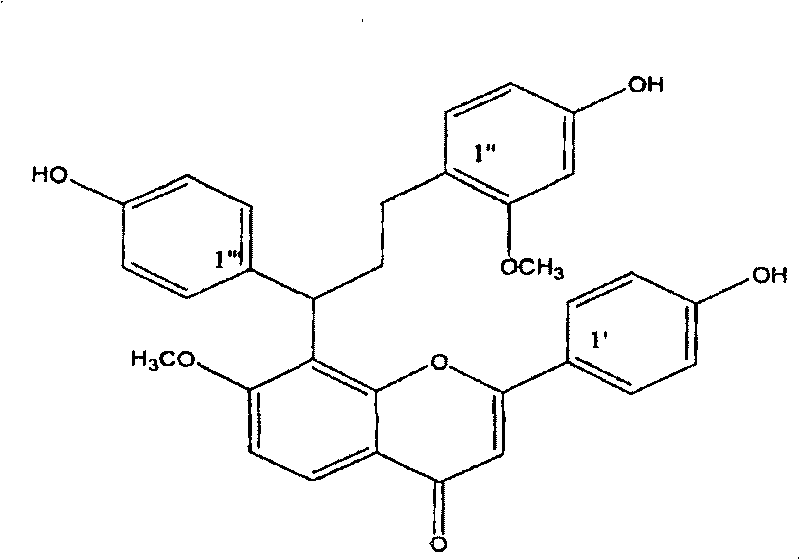

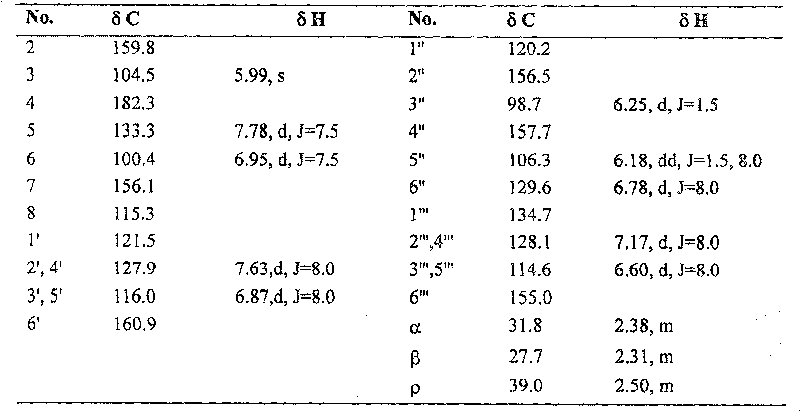

Separating purified new bisflavone compound from dragon's blood and preparation method thereof

A technology for separation and purification of flavonoids, which is applied in the field of medicinal phytochemical extraction technology, and can solve the problems that have not been seen before.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Weigh 100g of 60-80 mesh dragon’s blood jerky powder, add 1800mL of petroleum ether for Soxhlet extraction, the temperature of Soxhlet extraction is 75°C, the extraction time is 12 hours, and the residual petroleum ether is volatilized from the raffinate. 94.5 g of petroleum ether raffinate A was obtained; the above raffinate A was subjected to solid-liquid extraction with 300 mL of acetone at room temperature, repeated 3 times, the extracts were combined, concentrated with a rotary evaporator, and dried at 40°C to obtain acetone extract B 84.4g; the above-mentioned extract B was subjected to solid-liquid extraction with 300mL ethyl acetate at room temperature, repeated 4 times, and the residual ethyl acetate in the raffinate was evaporated to dryness to obtain 36.2g of ethyl acetate raffinate C; After dissolving the above raffinate C with methanol, add an equal amount of silica gel and mix evenly, remove the methanol by volatilization, grind the solid sample into powder...

Embodiment 2

[0031] Weigh 100g of 60-80 mesh dragon's blood, add 2000mL of petroleum ether for Soxhlet extraction, the temperature of Soxhlet extraction is 70°C, the extraction time is 15 hours, and the residual petroleum ether is evaporated from the raffinate to obtain petroleum Ether raffinate A 97.2g; the above raffinate A was subjected to solid-liquid extraction with 250mL acetone at room temperature, repeated 5 times, the combined extracts were concentrated with a rotary evaporator, dried at 45°C to obtain 86.7g of acetone extract B Carry out solid-liquid extraction with 250mL ethyl acetate above-mentioned extract B at room temperature, repeat 5 times, the residual ethyl acetate in the raffinate is evaporated to dryness, obtain ethyl acetate raffinate C 38.2g; Take above-mentioned extract After dissolving the residue C with methanol, add an equal amount of silica gel and mix evenly, volatilize to remove methanol, grind the solid sample into powder in a mortar, pass through an 80-mesh s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com