Hybrid plasma reactor

A hybrid plasma and plasma technology, applied in the fields of plasma, semiconductor/solid-state device manufacturing, discharge tube, etc., can solve the problems of low PR selectivity, chamber matching, narrow process window, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Exemplary embodiments of the present invention will now be described in more detail with reference to the accompanying drawings. In the following description, detailed descriptions of well-known functions and constructions incorporated herein are omitted for simplicity.

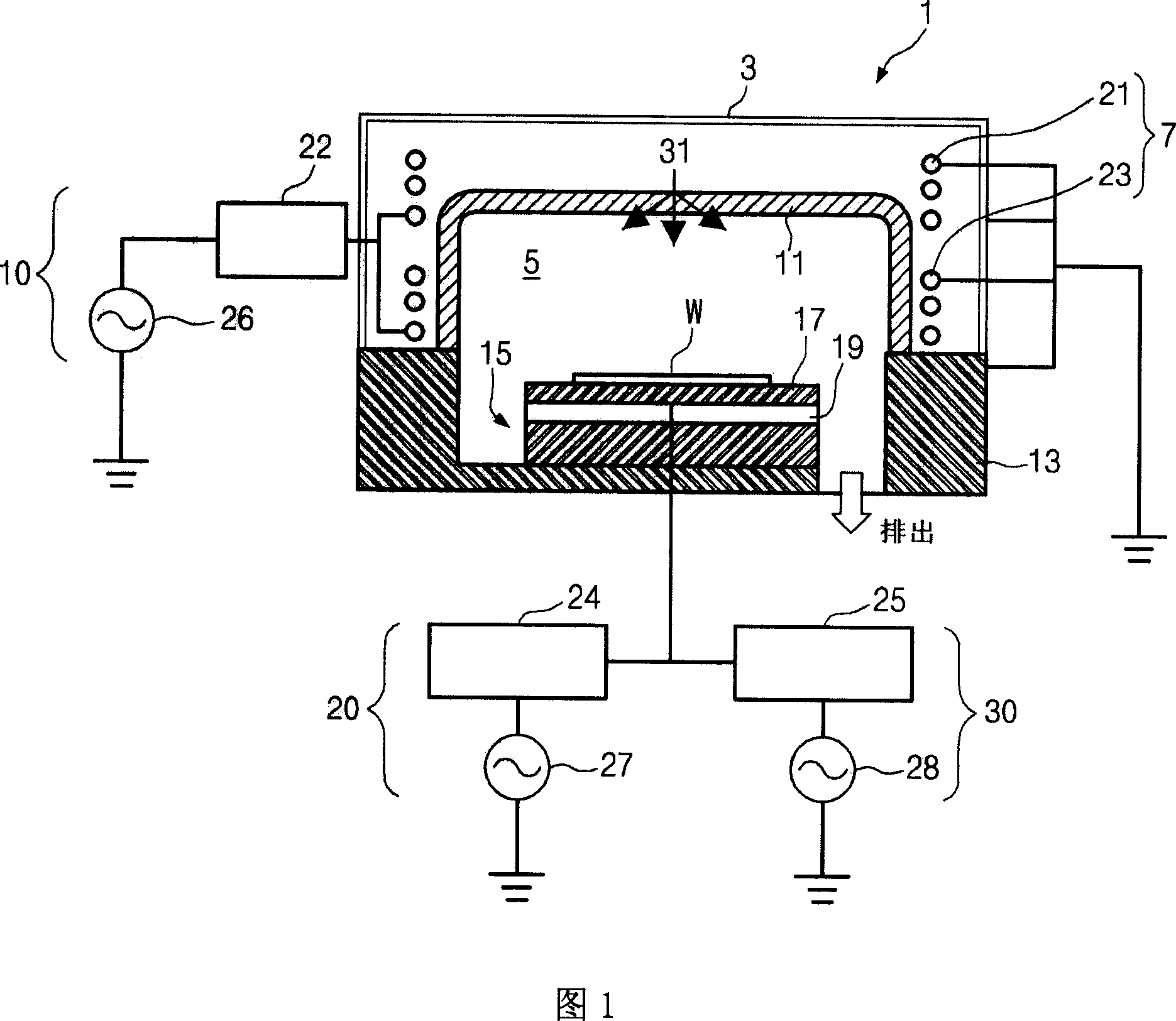

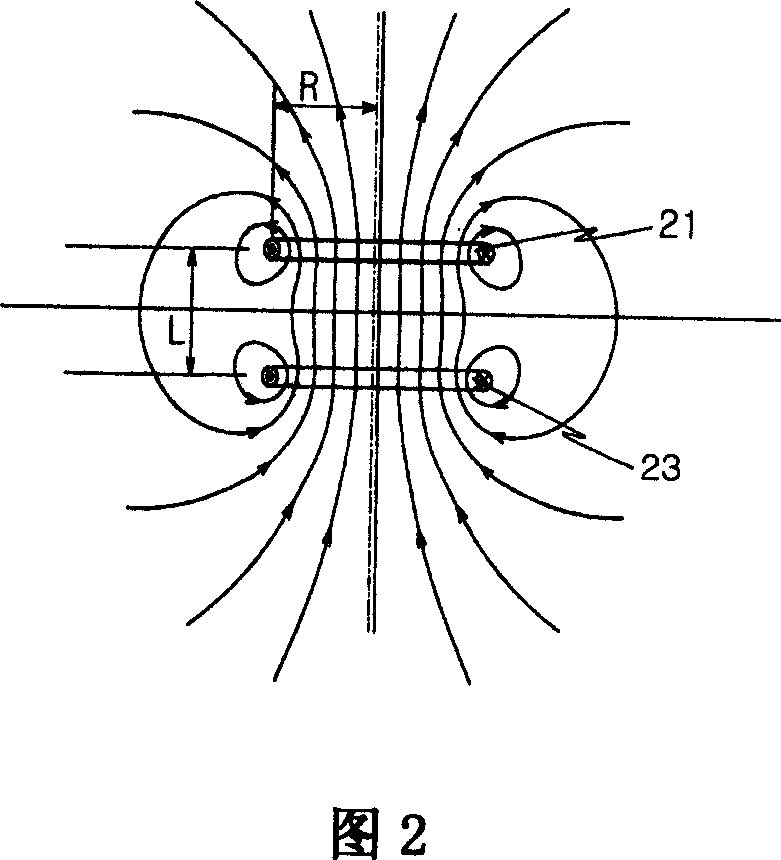

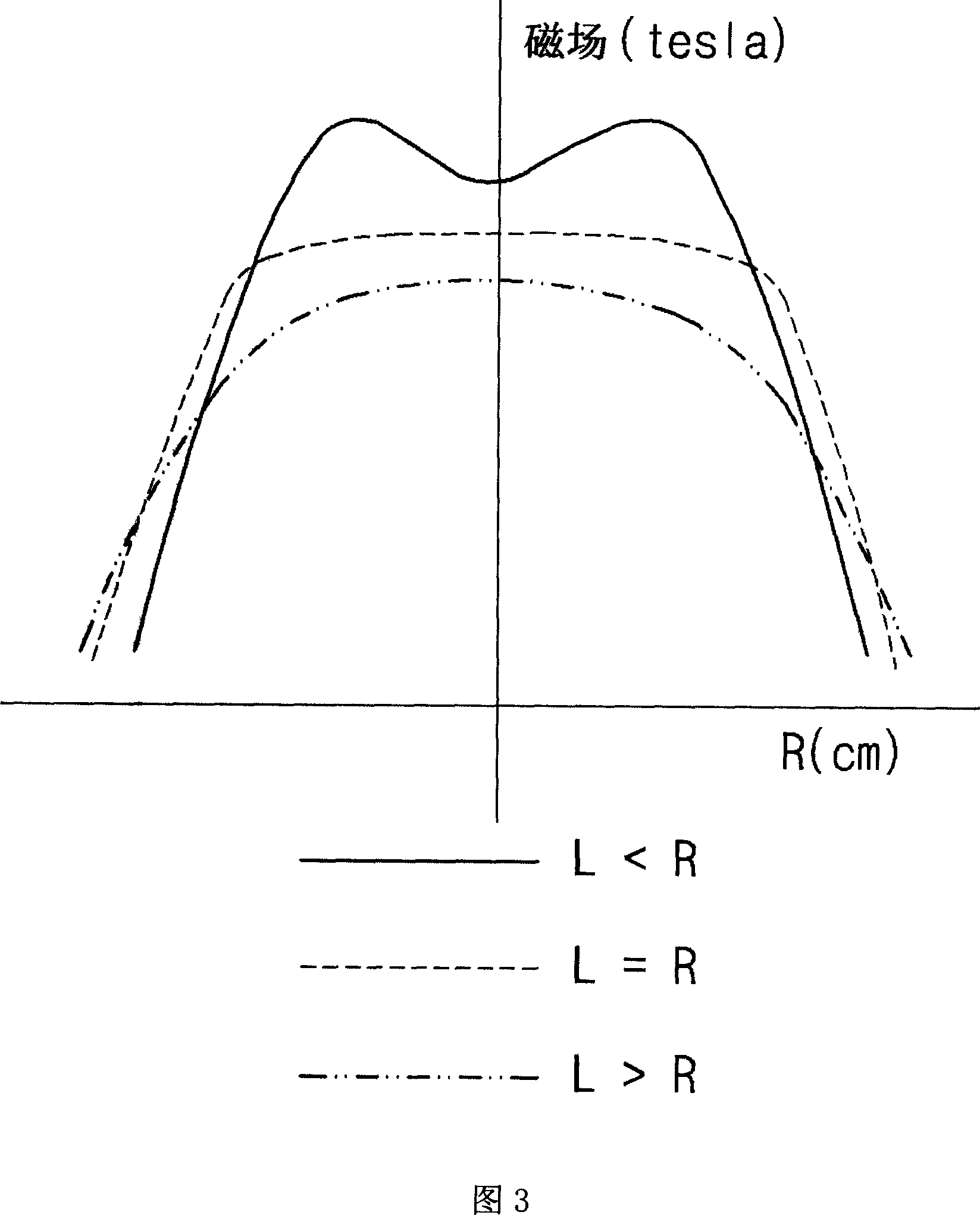

[0033] The present invention provides plasma properties (such as tunable plasma ion density, tunable ion energy distribution, tunable ion energy, tunable radicals, and low Ion-depleting plasma) hybrid type plasma generation apparatus and method. These plasma properties can be controlled using a multi-antenna coil structure, a pillar type dielectric window, an inductively coupled plasma (ICP) source unit provided above the chamber, and a hybrid frequency offset provided to the cathode.

[0034] FIG. 1 shows the configuration of a plasma reactor according to a first exemplary embodiment of the present invention. Referring to FIG. 1 , a plasma reactor includes an inductively coupled plasma (ICP) source ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com