Combined heat radiating module

A heat dissipation module and composite technology, applied in lighting and heating equipment, cooling/ventilation/heating renovation, cooling machine, etc. The effect of improving design margin, improving quality and saving assembly space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

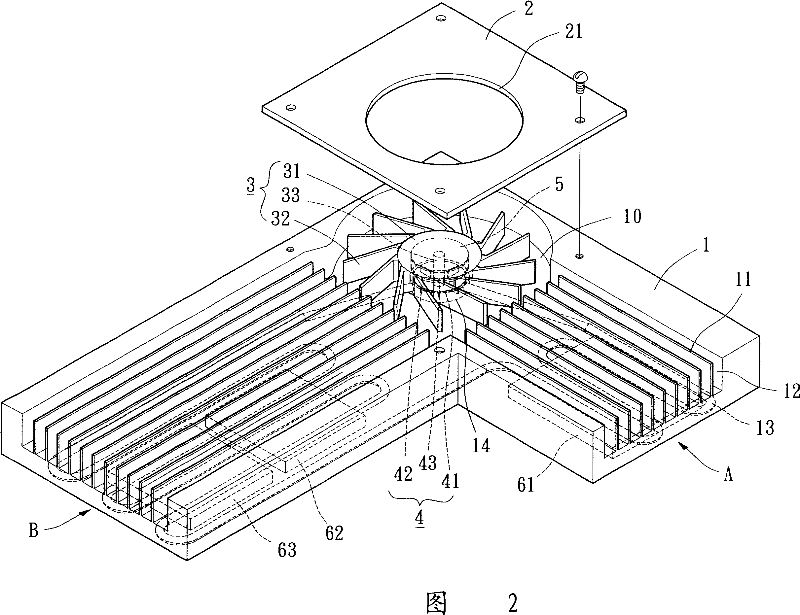

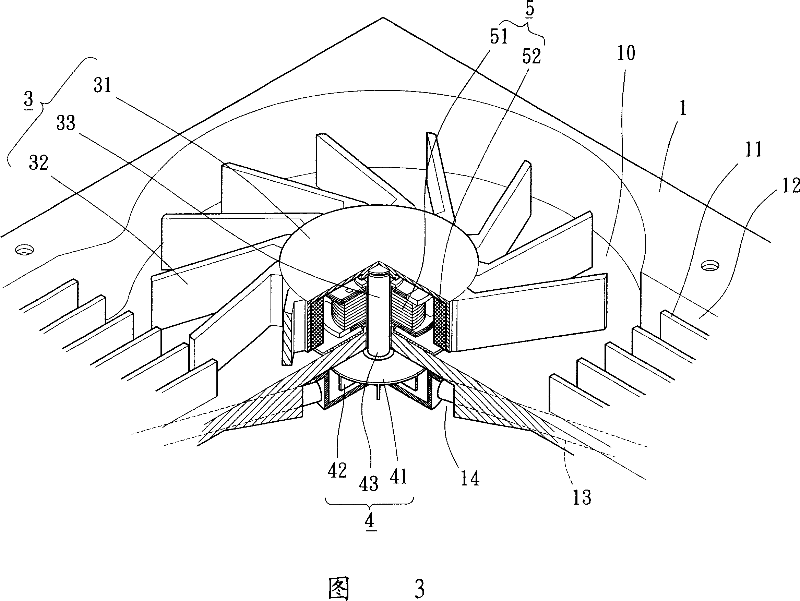

[0024] In order to have a further understanding and understanding of the purpose of the present invention, technical features and advantages thereof, the number of preferred embodiments of the present invention is cited hereby, and the accompanying drawings are described in detail as follows:

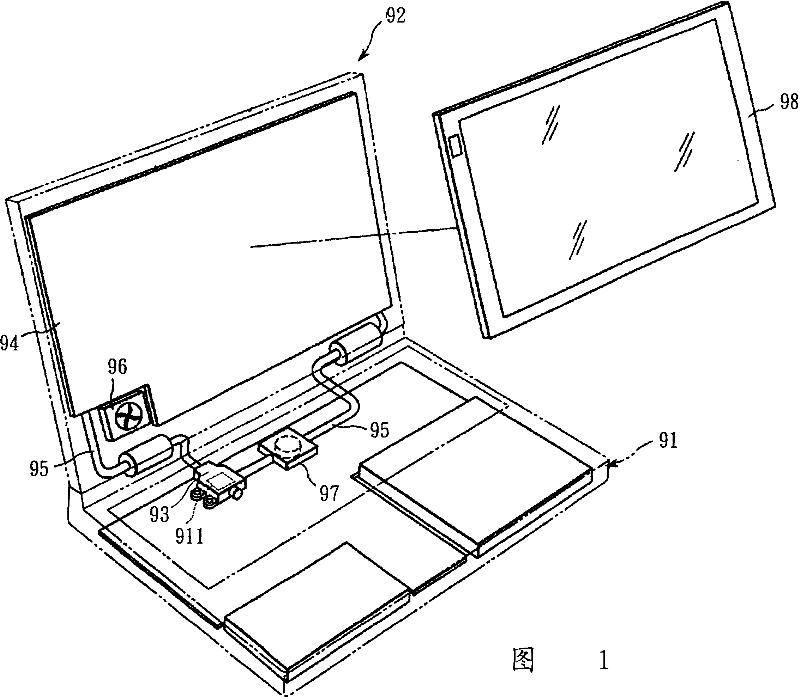

[0025] Please refer to Figures 2 and 3, the first embodiment of the present invention, a composite heat dissipation module, including a heat dissipation plate 1, a cover plate 2, a fan wheel unit 3, a pump unit 4 and at least one power source 5. It is used to perform synchronous or asynchronous air cooling and liquid cooling on at least one object 61 , 62 and 63 to be dissipated. The composite heat dissipation module can be assembled in the casing of a notebook computer, a desktop computer or other electronic devices, and the heat dissipation objects 61, 62 and 63 can be high-power integrated circuits, display panels or electronic components, such as central processing Processor CPU, LC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com