Eccentric shaft with adjustable eccentricity

A technology of eccentric shaft and eccentric distance, applied in the direction of eccentric shaft, clamping, supporting, etc., can solve the problem that the eccentric amount cannot be directly adjusted, and achieve the effect of convenient and fast adjustment of eccentric amount, lower manufacturing cost and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

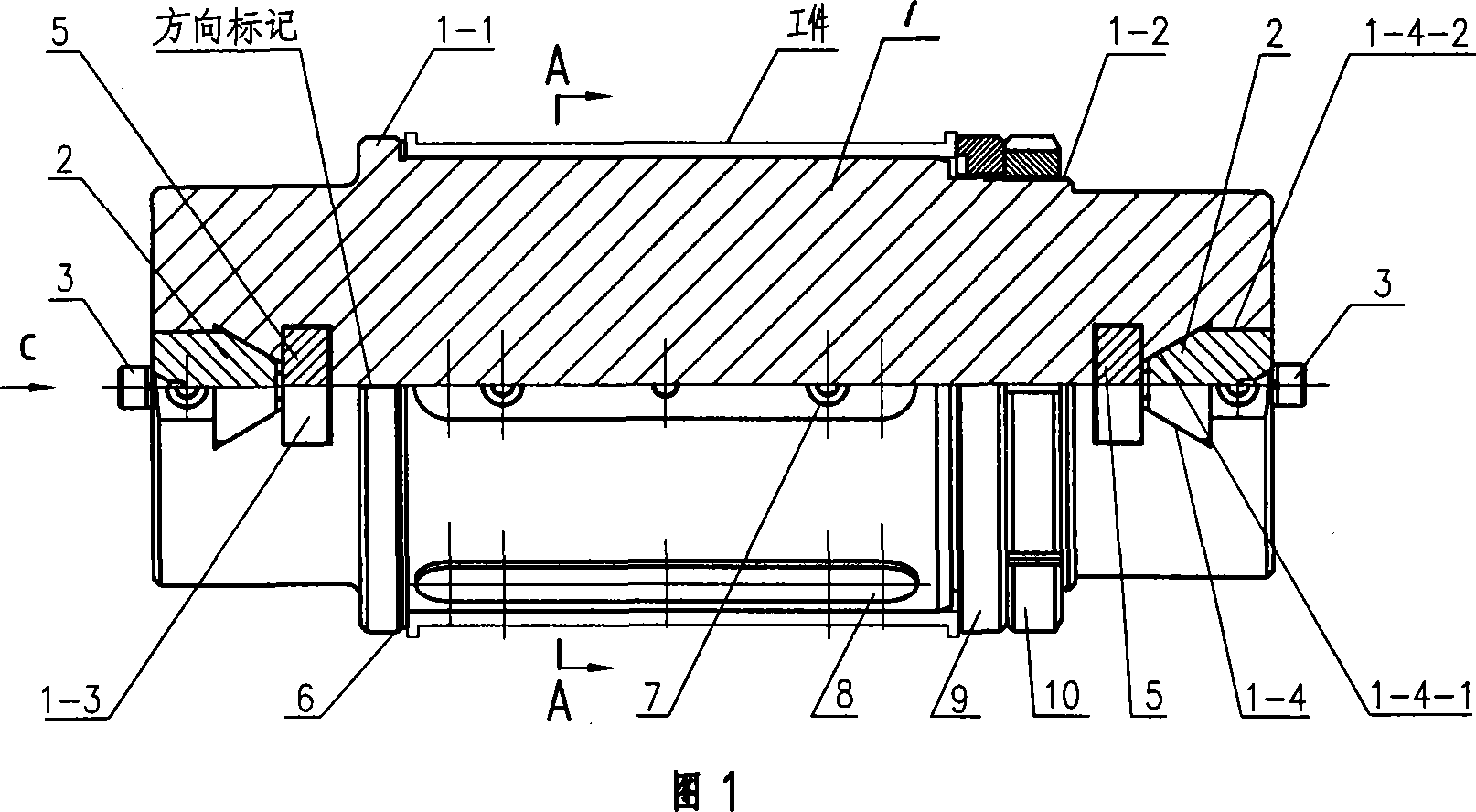

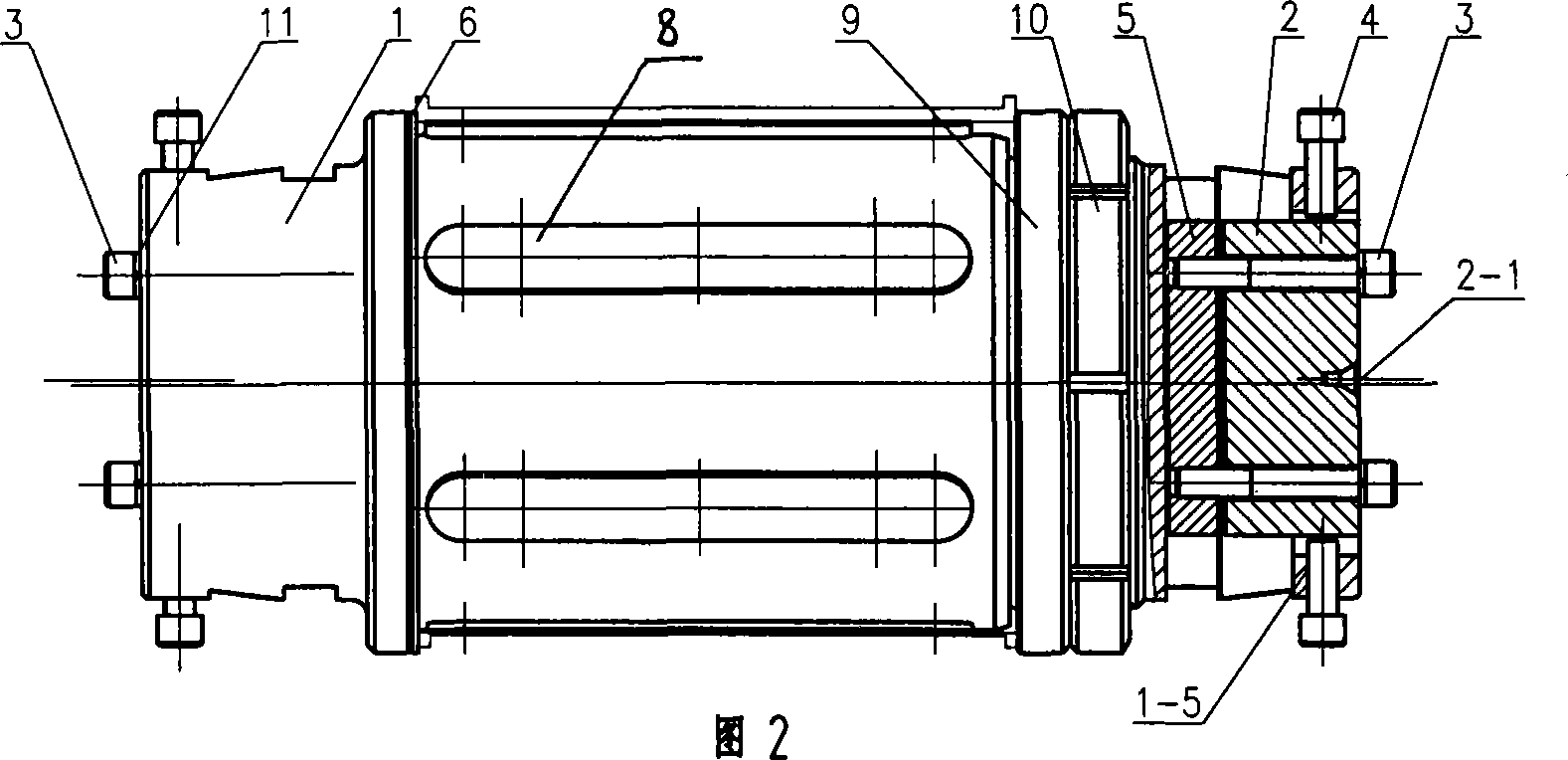

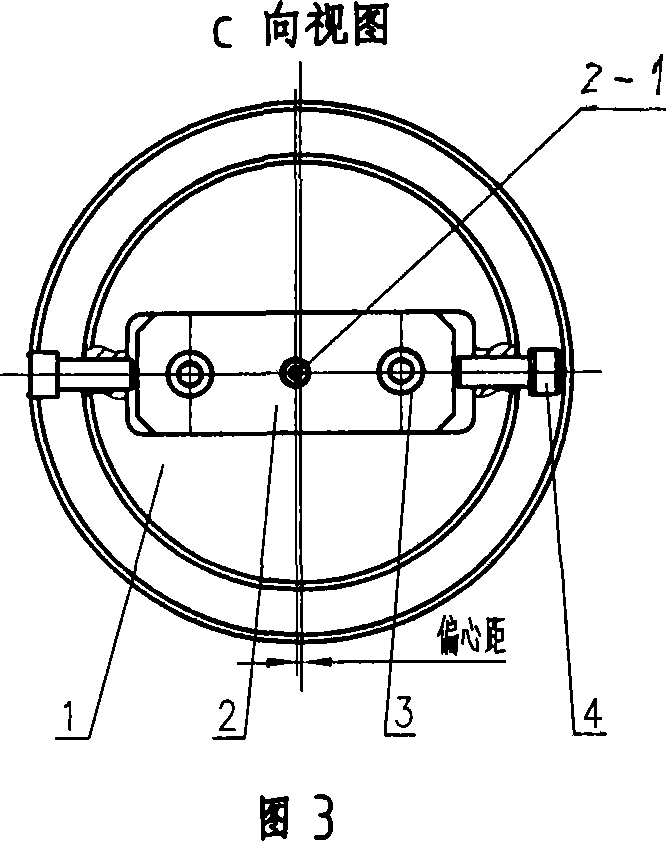

[0030] The present invention will be further described below through the description of specific embodiments with reference to the accompanying drawings.

[0031] The specific implementation is shown in Figures 1 to 4.

[0032] An eccentric shaft with adjustable eccentricity mainly used for processing thin-walled eccentric sleeve workpieces, comprising a mandrel body 1, one side of the mandrel body 1 has a shaft shoulder 1-1, and the other side has an external thread section 1- 2. The external thread section 1-2 is set with a washer 9 and a lock nut 10 that can be screwed with the external thread; the two ends of the mandrel body 1 are respectively provided with symmetrical multi-edged through holes 1-3 along the radial direction; The prismatic through hole 1-3 is provided with a locking block 5 that is fitted and slidable; the two axial ends of the mandrel body 1 are respectively provided with symmetrical wedge-shaped sliding blocks that communicate with the multi-primed thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com