Method for producing acetylene for cracking natural gas by micro discharge

A technology of natural gas and acetylene, which is applied in the field of micro-discharge cracking of natural gas to produce acetylene, which can solve the problems of high energy consumption and short electrode life, and achieve the effects of reducing energy consumption, solving stability problems, and improving methane conversion rate and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

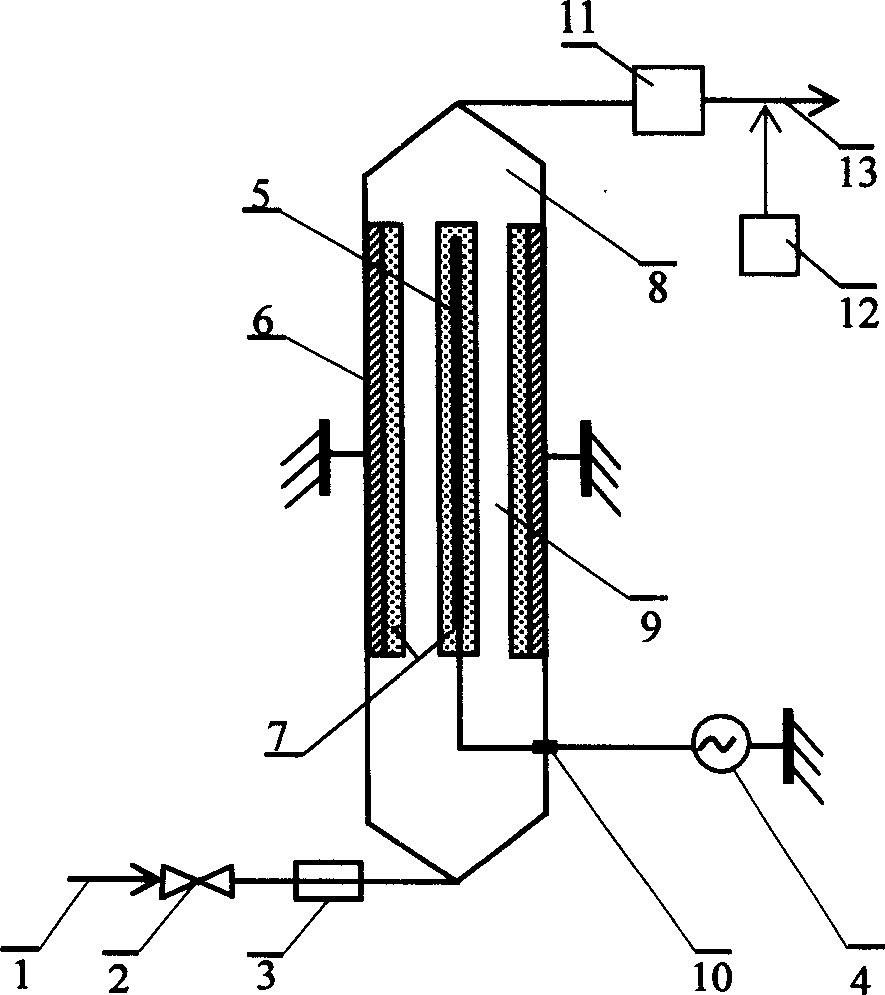

[0032] Specific embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

[0033] Step 1. In the plasma reactor 8 in the figure, a dielectric barrier discharge component is placed, wherein the metal-processed discharge electrode 5 is coated with a thin dielectric layer 7 on the periphery, and the ground electrode 6 made of metal is close to the reactor box. On the other side, a thin layer of dielectric layer is coated with a thickness of 0.2 mm to 1 mm, and a discharge gap 9 is formed between the discharge electrode and the ground electrode, and the distance is 0.2 to 2 mm.

[0034] Step 2. The frequency of the medium-frequency high-voltage power supply 4 in Figure 1 is 400 Hz to 10 kHz, and the high voltage delivered is applied to the discharge electrode 5 through the insulator 10, and a strong ionization discharge electric field is established with the ground electrode 6, and a high-voltage disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com