Process for concentrating, assimilating and treating flat plate film sludge synchronously

A technology of digestion treatment and flat membrane, applied in water/sludge/sewage treatment, biological water/sewage treatment, sustainable biological treatment, etc., can solve the problems of reducing the organic matter content of sludge, low treatment cost and poor effect, etc. Achieve the effect of reducing the content of organic matter, reducing the treatment cost, and slowing down the fouling of the membrane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

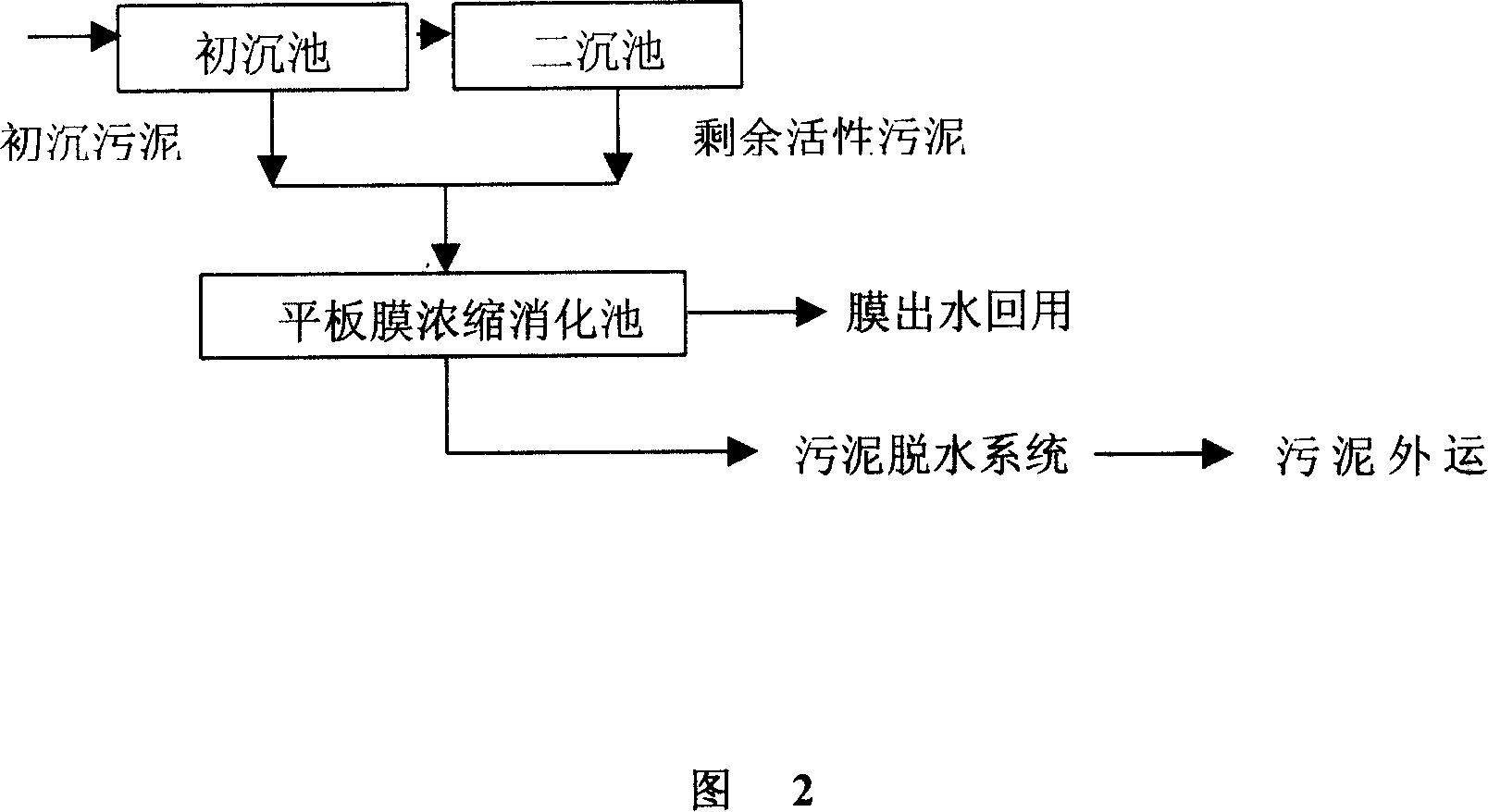

[0012] The mixed sludge of the primary sludge and the residual activated sludge of the secondary sedimentation tank is treated, and the continuous operation mode of continuous sludge feeding and continuous water outlet and intermittent operation is adopted in the whole operation process. At the initial stage of start-up, after inoculating part of the digested sludge into the tank, pump the sludge to be treated directly into the tank to a certain liquid level, the initial sludge concentration is 5g / L; the hydraulic retention time is 1.1d ; Sludge residence time 30d; Air-water ratio 50:1; Membrane effluent flux 10L / m 2 .h; Membrane effluent water quality COD<100mg / L, while using the effluent pump to continuously discharge the water, continuously pump the same flow of sludge to be treated to maintain the liquid level in the pool. After a certain period of operation, the sludge concentration in the pool reaches 30g / L, and the VSS digestion rate is greater than 40%. At this time, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com