Method for preparing nano tea polypherals rare earth complexes by liquid phase method

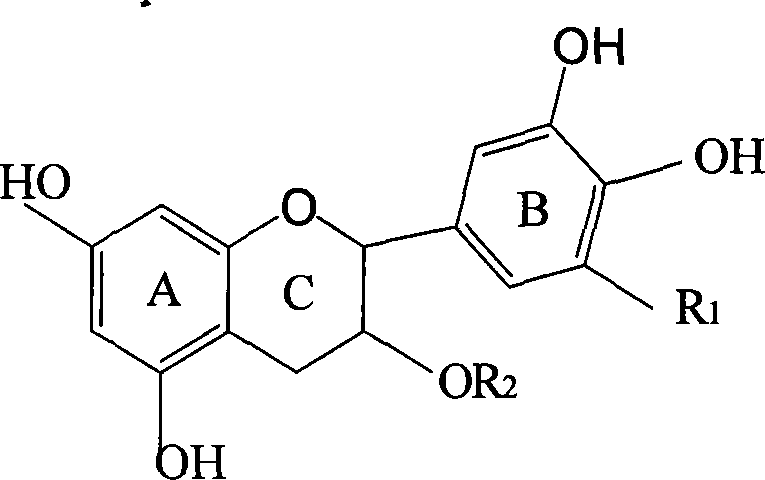

A technology of rare earth complexes and tea polyphenols is applied in the field of preparation of rare earth complexes of tea polyphenols, which can solve the problems of rare earth synthesis and application of nano-tea polyphenols, etc., which have not seen relevant reports, and achieve the effect of good anti-aging performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0026] In 100ml 0.1M tea polyphenol solution, add 100ml 20% concentration of lanthanum chloride aqueous solution, after magnetic stirring, at room temperature, add 1M NaOH drop by drop to pH 6.0, continue to stir for 24h after the dropwise addition, the resulting product The centrifugation is carried out at 4000r / min, the precipitate is washed with distilled water for 3 times, centrifuged and dehydrated, and the nano-tea polyphenol lanthanum complex is separated into a solid. The solid matter was concentrated in a drying oven at 340K for 24 hours under vacuum to obtain a solid powder of the complex.

example 2

[0028] In 100ml 0.1M tea polyphenol solution, add 100ml 40% concentration of cerium chloride aqueous solution, stir magnetically, at room temperature, add 1M NaOH drop by drop to pH 7, stir for 24h after the dropwise addition, and the resulting product is dissolved at 4000rr / min for centrifugation, the precipitate was washed 5 times with distilled water, and centrifugally dehydrated to obtain a solid nano-tea polyphenol cerium complex. The solid matter was concentrated in a drying oven at 340K for 24 hours under vacuum to obtain a solid powder of the complex. .

example 3

[0030] In 100ml 0.1M tea polyphenol solution, add 100ml 50% chlorinated symbiotic rare earth aqueous solution, stir magnetically, and add 1M NaOH dropwise at room temperature until the pH is 4.5, stir for 24 hours after the dropwise addition, the product is Centrifugal separation at 4000r / min, the sediment was washed 8 times with distilled water, and centrifugal dehydration to obtain the solid nano-tea polyphenol symbiotic rare earth complex. The solid matter was concentrated in a drying oven at 340K for 24 hours under vacuum to obtain a solid powder of the complex.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com