Austenitic stainless steel with excellent anti-bacterium capability

A technology of austenitic stainless steel and characteristics, applied in the field of austenitic stainless steel, can solve the problems of increasing cost, reducing stainless steel corrosion resistance, corrosion resistance decline, etc., to meet the requirements of guaranteed corrosion resistance, excellent antibacterial function, excellent antibacterial performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Sample preparation: according to the composition of the austenitic antibacterial stainless steel of the present invention, smelt with a 25kg vacuum induction furnace, then through forging, hot rolling and annealing, repeated cold rolling-annealing-pickling, to make a 0.8mm plate, the plate is in After being kept at 1050° C. for 7 minutes in a vacuum furnace, aging was performed at 700° C. for 6 hours. A sample of 40×40 mm was cut from the above plate, and then tested for antibacterial performance. The cast sample is smelted in a 25kg vacuum induction furnace, and an 8mm thick test piece is cut in the direction perpendicular to the ingot axis. The above heat treatment process is adopted, and then processed into a 40×40×5mm antibacterial test sample.

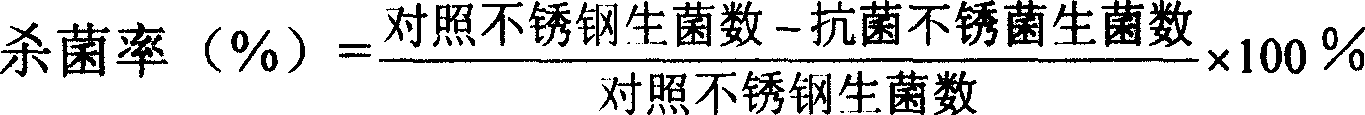

[0017] Antibacterial performance test: The antibacterial test adopts the antibacterial test method of the Japan Antibacterial Association "Japanese Industrial Standard: Antibacterial Test Method and Antibacterial Effect of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com