Hollow photon crystal optical fiber based Fabry-perot interferometer sensor and its production method

The technology of a hollow-core photonic crystal and a manufacturing method is applied in the direction of using an optical device to transmit a sensing member, a cladding fiber, an optical waveguide light guide, etc. Extraction and other problems to achieve the effect of small temperature change coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

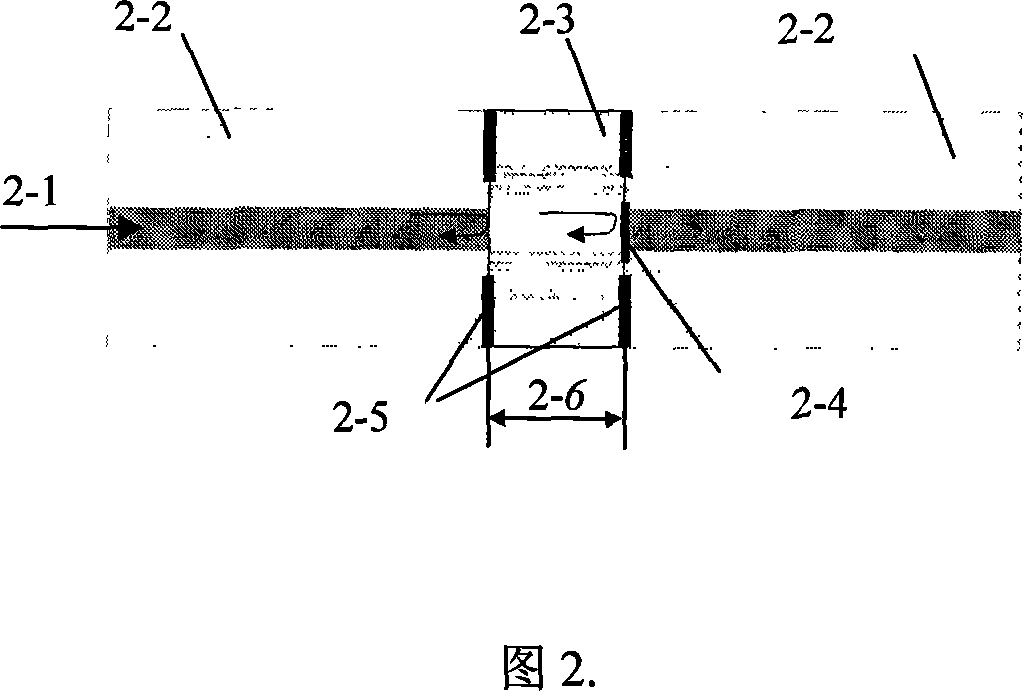

[0015] Referring to Fig. 2, the new EFPI interference sensor is composed of two ordinary communication single-mode optical fibers 2-2 and a hollow-core PCF optical fiber 2-3, and the two ends of the hollow-core PCF optical fiber 2-3 are respectively connected to two ordinary communication One end of the single-mode optical fiber 2-2 is fusion-spliced. The hollow-core PCF fiber 2-3 forms the F-P interference cavity of the sensor, and the end faces of the ordinary communication single-mode fiber 2-2 fused with the hollow-core PCF fiber 2-3 respectively form two reflection surfaces of the F-P cavity.

[0016] In order to further improve the signal strength of the EFPI sensor, the end face of the common communication single-mode optical fiber 2-2 at the right end is plated with Ti 2 o 3 film or other reflective film. In order to ensure the mechanical strength of the welding point after coating, Ti 2 o 3 The film or other reflective films can only be coated on the core of the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com