Optical path glue-free miniaturized MUX and DEMUX optical assembly

A technology of optical components and optical paths, which is applied in the fields of optical communication and 5G, can solve the problems affecting the insertion loss of MUX and DEMUX devices, uneven glue layer thickness, and poor parallelism, and achieve low cost and small spectral variation coefficient with temperature , The effect of low insertion loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

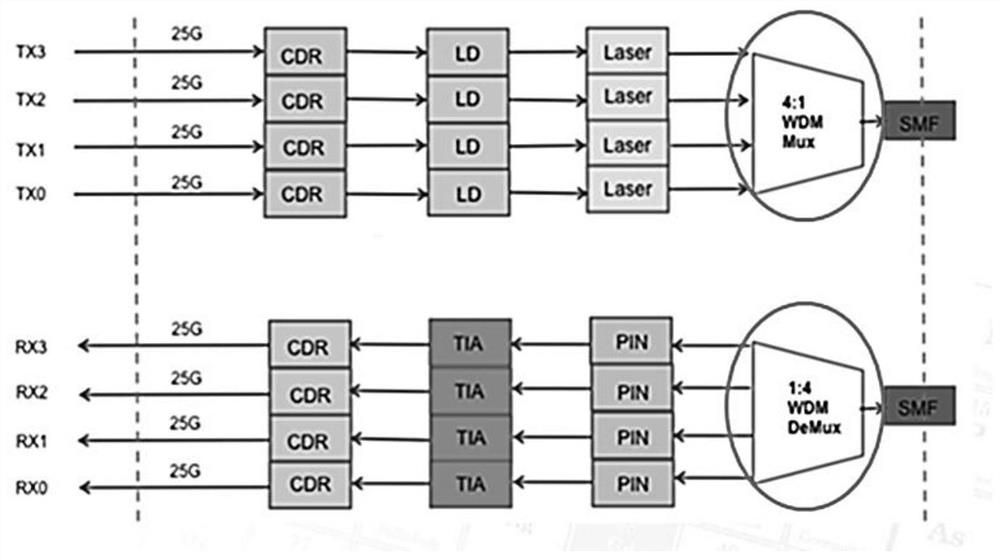

[0044] like Figure 5 to Figure 8 As shown in one, the optical path of this embodiment has no glue, miniaturized MUX and DEMUX optical components, which include:

[0045] Optical plate 1, which has through grooves running through its opposite sides;

[0046] N first WDM filter films 2, which have different working wavelengths and are arranged side by side on the through groove on one side of the optical plate 1;

[0047] M optical films 3, which straddle the through groove on the other side of the optical plate 1 and correspond to N first WDM filter films 2, M optical films 3 are used for partial reflection and partial transmission of N The optical signal reflected back by the first WDM filter film 2 .

[0048] Wherein, as a possible implementation manner, further, the optical flat plate 1 may have a parallelogram or trapezoidal structure, and the material of the optical flat plate 1 is made of optical glass, ceramics, silicon or optical crystal material, and The opening wa...

Embodiment 2

[0058] like Figure 9 to Figure 11 As shown in one, the present embodiment is roughly the same as Embodiment 1, the difference is that the M optical films 3 are M total reflection films, as a better choice, the M total reflection films M total reflection regions on the total reflection film that can be integrally formed.

[0059] Wherein, one end of the through groove on the side corresponding to the N first WDM filter films 2 of the optical plate 1 leaves a gap for optical signal input. On the first WDM film and the optical signal adapted to its operating wavelength is transmitted by the first WDM filter film, and the optical signal different from its operating wavelength is reflected to the optical film at one end of the M optical films 3, and accordingly Regular reciprocating reflection to the rest of the first WDM filter film and optical film.

[0060] That is, a reflective mirror coated with a high-reflection film is pasted on one side of the two parallel planes before ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com