Automobile quarter simulated suspension system and shock absorber characteristic integral test platform

A technology of comprehensive test bench and suspension system, which is applied in the field of automobile quarter simulation suspension system and shock absorber characteristic comprehensive test bench field, which can solve the problem of not meeting the needs of test modeling, simple test conditions, and mechanical friction. Large and other problems, to achieve the effect of convenient suspension test, simple bench structure and small mechanical friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

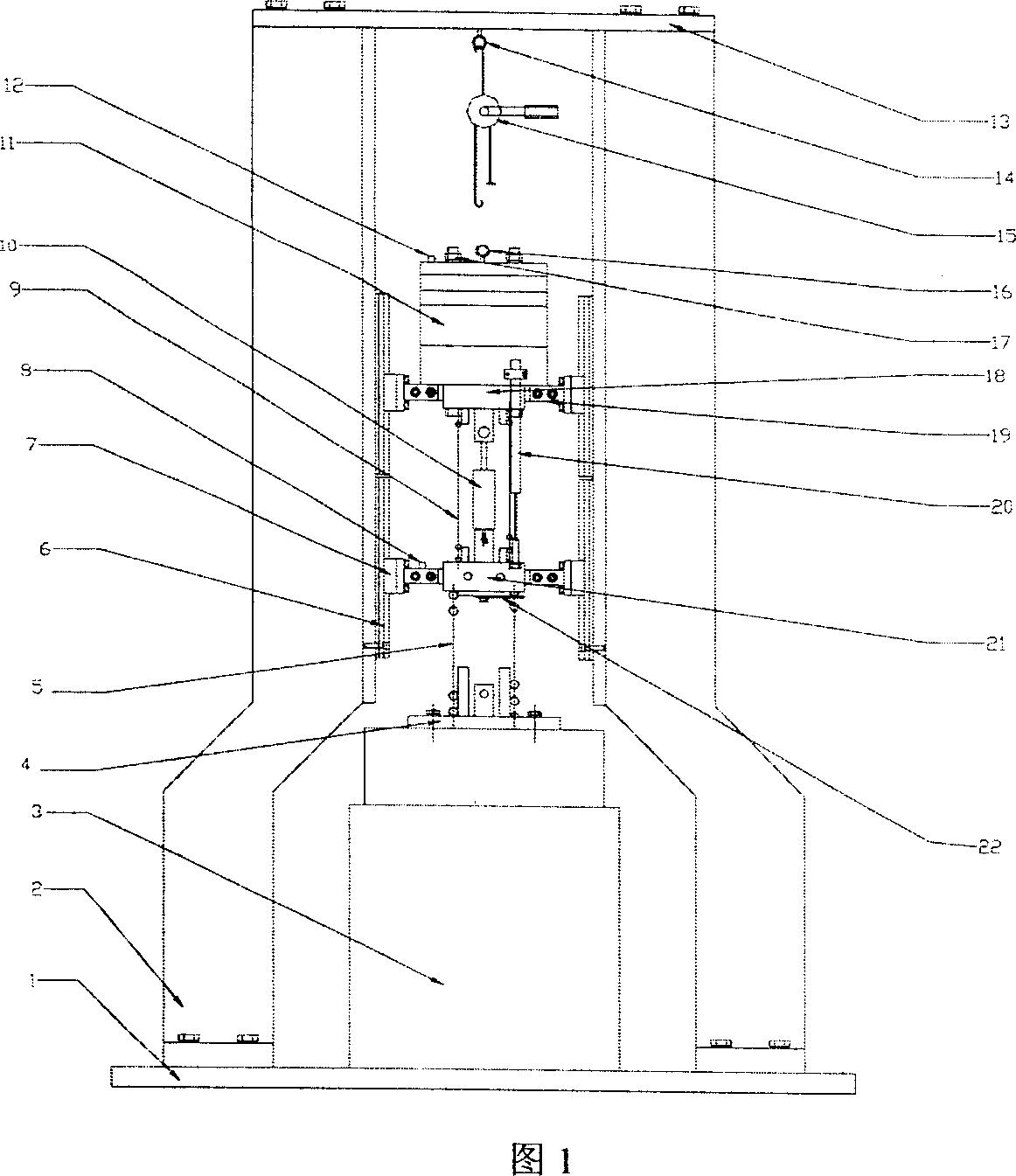

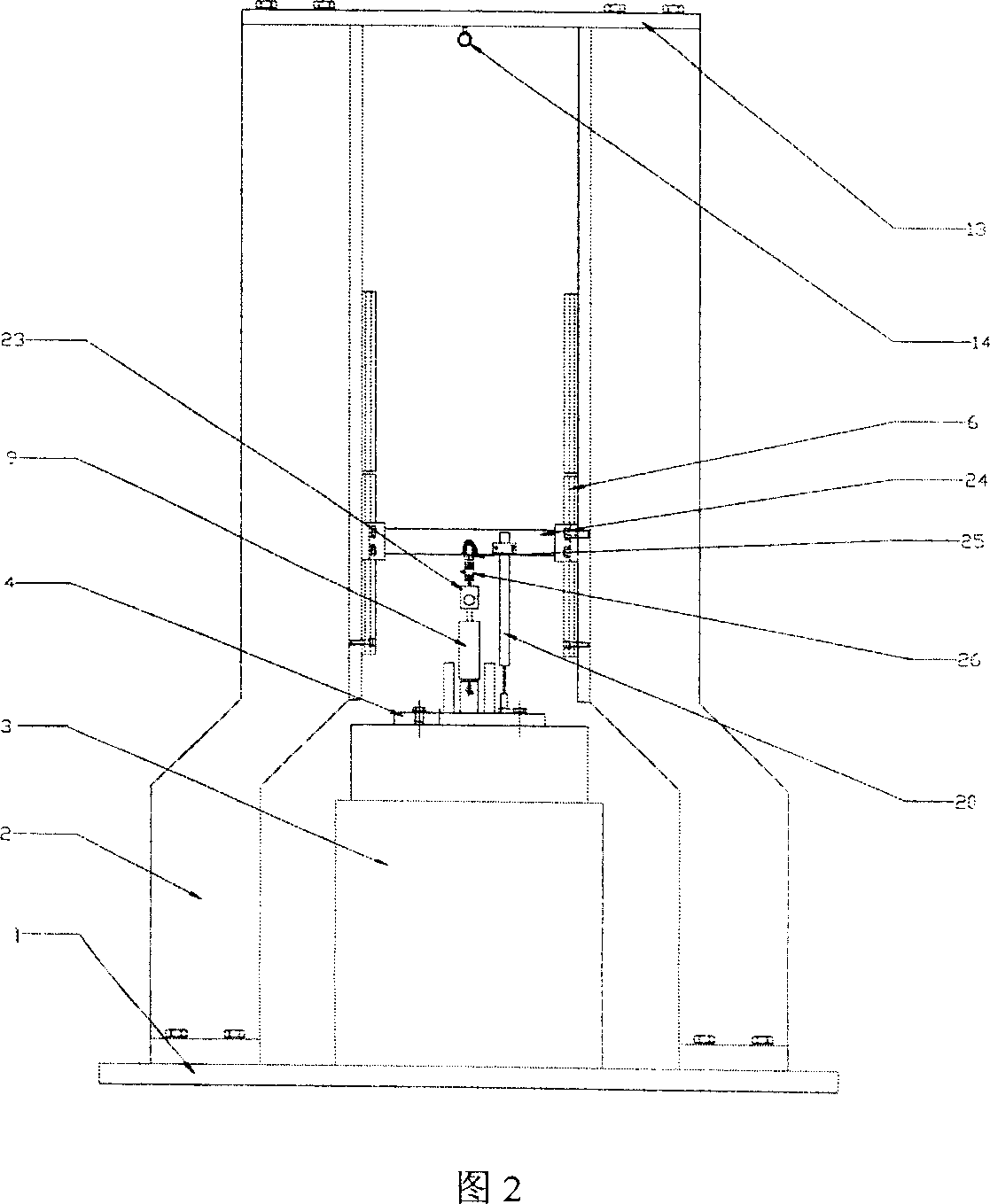

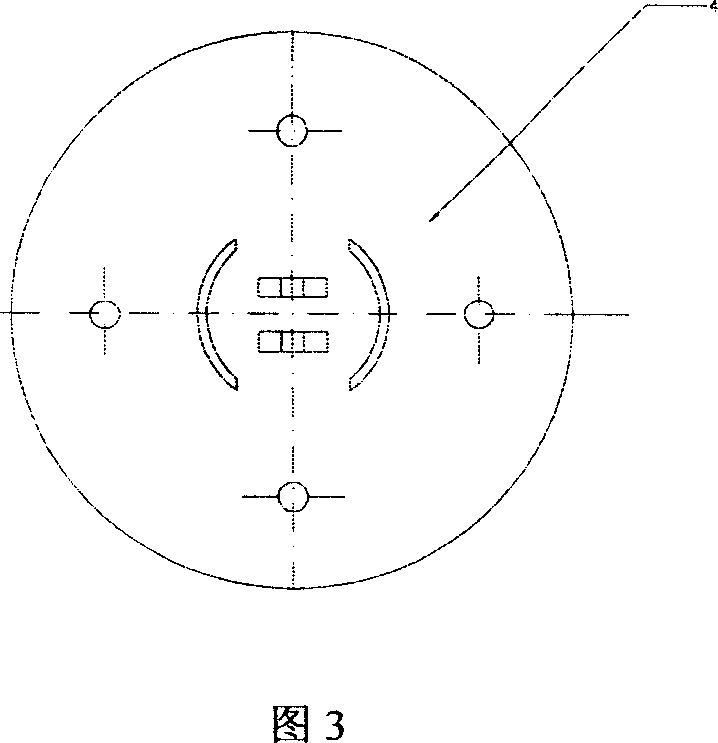

[0018] The automobile quarter simulated suspension test bench in Fig. 1 includes a base plate 1, a column 2, an electric vibrating table 3, a tray 4, a lower spring 5, a vertical linear ball guide rail 6, a slider 7, an acceleration sensor 8, an upper spring 9, Shock absorber 10, counterweight 11, acceleration sensor 12, top plate 13, lifting ring 14, lever block 15, lifting ring 16, fastening bolt 17, upper bracket 18, connecting fork 19, differential pressure transformer displacement sensor 20 , the lower bracket 21, the spring pressure plate 22, the base plate 1, the left and right columns 2 and the top plate 13 form a frame structure. There are two sections in parallel, one section is provided in parallel at the left and right of the lower part, a tray 4 is fixed on the electric vibrating table 3, and a lower spring 5 is arranged on the tray 4. The lower spring 5 is equivalent to a tire of equal stiffness, and the lower spring 5 is provided with a Lower support 21, lower s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com