Hoe and method for forming hoe

A hoe and hoe board technology, which is applied in the field of overall forging and forming technology of hoe, can solve the problems of poor appearance and shape, difficult to guarantee quality, poor mechanical strength, etc., and achieve easy control of process conditions, reduced machining workload, and difficult machining Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

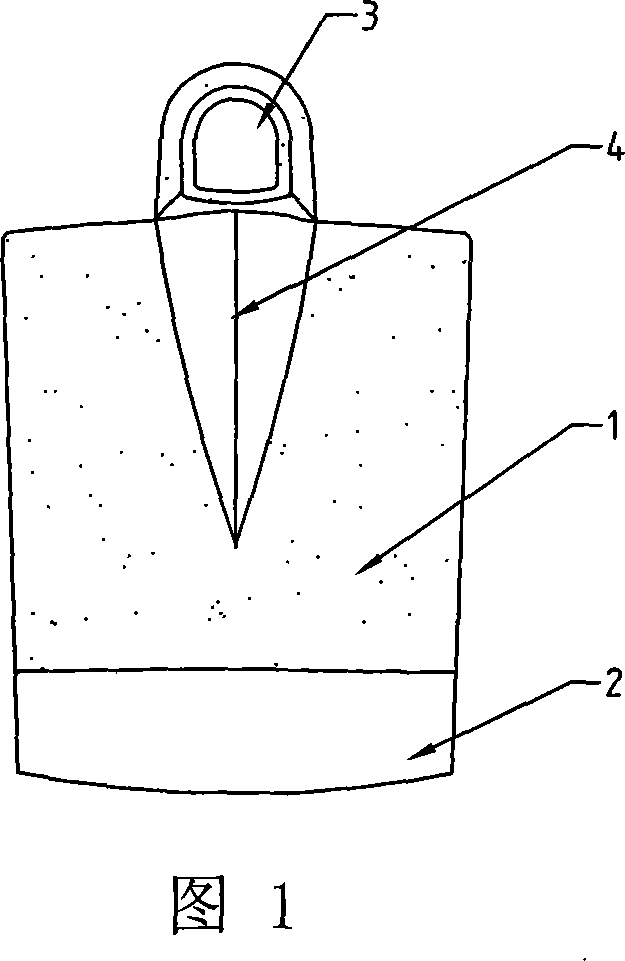

[0025] Accompanying drawing 1 shows a kind of H316 hoe, comprises hoe board 1 and hoe weng 3, hoe board 1 front end has hoe blade 2, hoe board 1 rear end has the hoe weng 3 that contracts and transitions into one, and the hole of hoe weng 3 forms an arch In the lower square, there is a ridge-shaped tendon 4 at the junction of the hoe Weng 3 and the hoe board 1 .

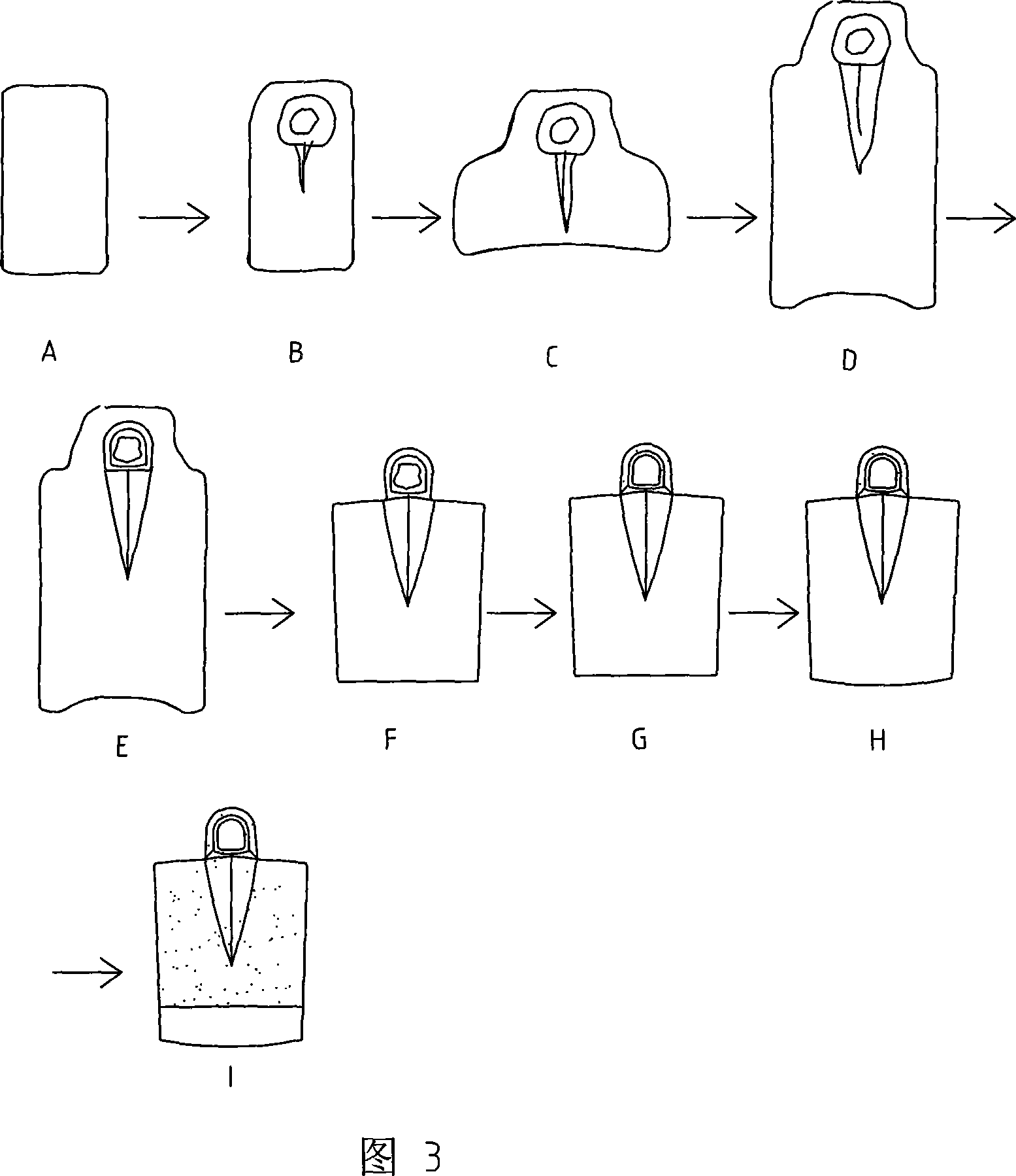

[0026] Accompanying drawing 3 represents the method step of H316 hoe forming:

[0027] Figure 3A is to determine the weight of the steel billet according to the size of the required workpiece size and cut it into a billet, and heat the billet in a furnace to obtain the shape of the high-temperature billet;

[0028] Fig. 3B shows that the positioning of the lath-shaped high-temperature blank is punched down to the concave hole;

[0029] Fig. 3C shows the slab-shaped high-temperature blank that has been punched with the lower concave hole, and the remaining part is stretched wide by mechanical force to form the requir...

Embodiment 2

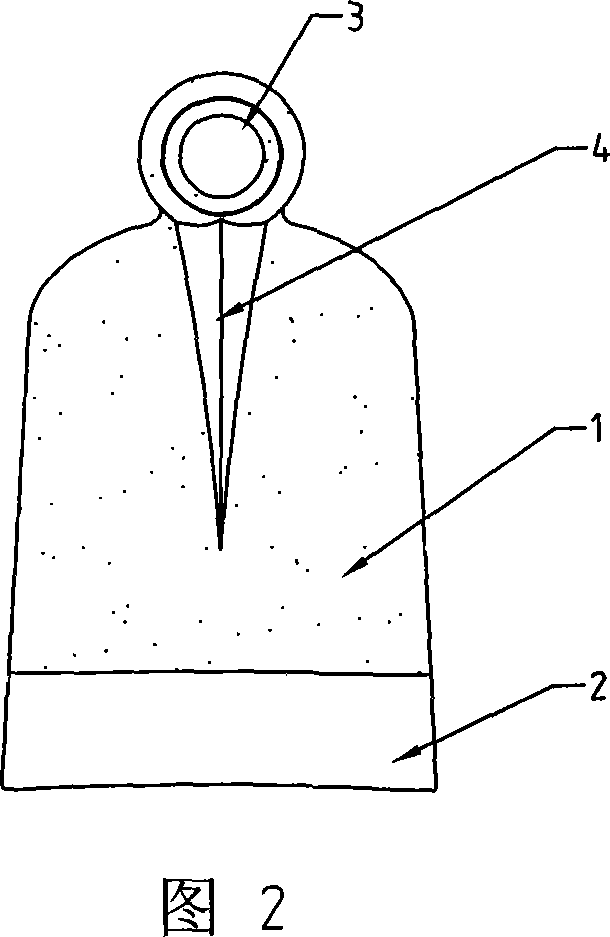

[0037] Accompanying drawing 2 shows is a kind of H304 hoe, comprises hoe plate 1 and hoe weng 3, hoe plate 1 front end has hoe blade 2, hoe plate 1 rear end has the hoe weng 3 that shrinks and transitions into one, and the hole of hoe weng 3 forms It is circular, and there is a ridge-shaped tendon 4 at the junction of the hoe Weng 3 and the hoe board 1 .

[0038] The method step of H304 hoe forming is:

[0039] 1. Determine the weight of the steel billet according to the size of the required workpiece size and cut it into a billet, and heat the billet in the furnace to form a high-temperature billet;

[0040] 2. Depending on the shape of the high-temperature blank, choose to directly position and punch the strip-shaped high-temperature blank into the pit, or choose to press it into a strip shape by mechanical forging and then position and punch down the pit;

[0041] 3. After the slab-shaped high-temperature blank has been punched with the lower concave hole, the remaining pa...

Embodiment 3

[0050] This example is a kind of H316 hoe, and structural shape is with embodiment 1.

[0051] Its forming method is to increase the embossing product mark step on the hoe blank in the step F of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com