Multi-stage inner-circulation nitration-denitrification biological denitrogenation reactor

A biological denitrification, fluidized bed reactor technology, applied in the field of high-concentration ammonia nitrogen-containing industrial sewage treatment, can solve the problems of large facility footprint, poor operation stability, large engineering investment, etc., and achieves low operating costs and impact resistance. The effect of strong capacity and low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] An embodiment of the present invention will be given below in conjunction with the accompanying drawings, and the structure and working principle of the present invention will be further described through the embodiment. It is necessary to specify here that the specific implementation of the present invention is not limited to the forms in the examples. According to the disclosed content of the present invention, those skilled in the art can also implement in other specific ways. Therefore, the examples It cannot be understood as the only specific embodiment of the present invention.

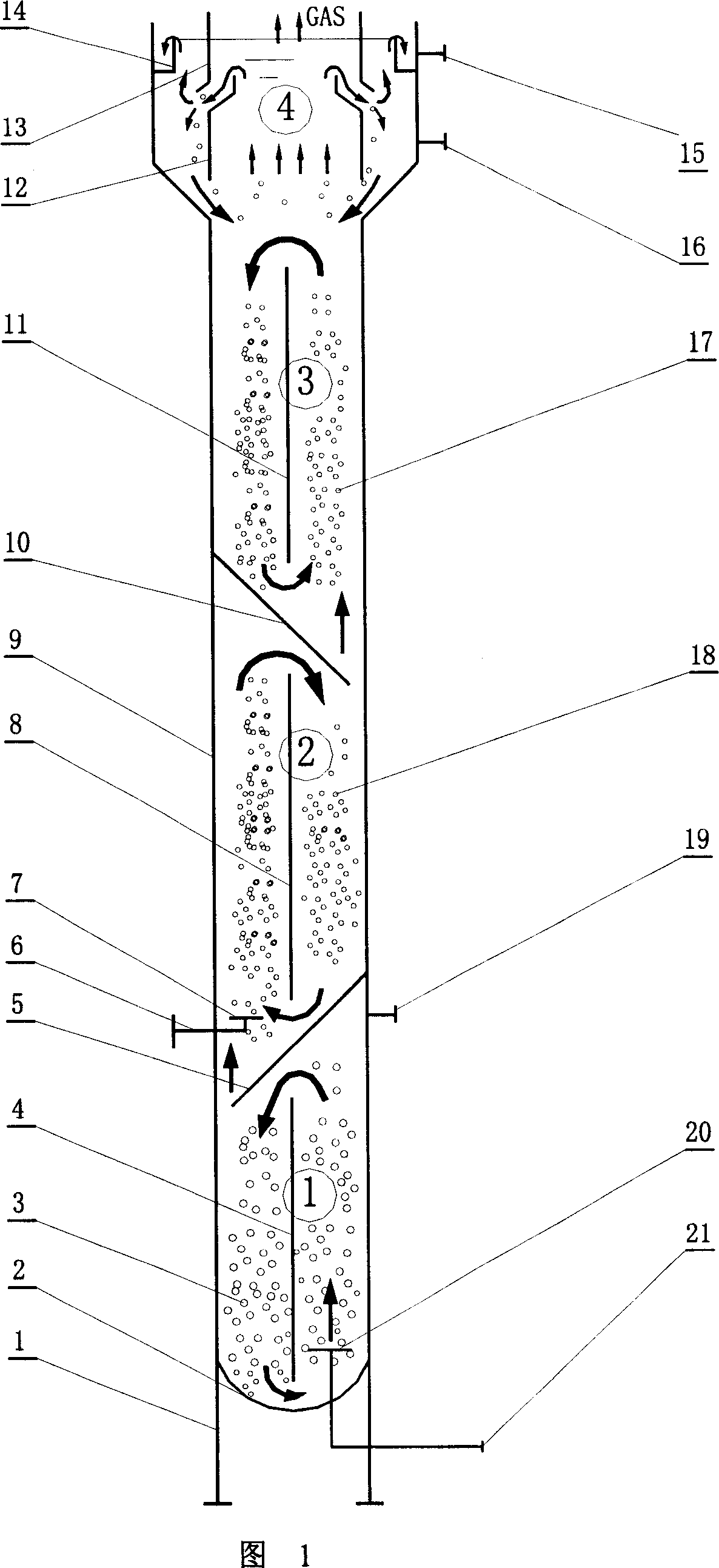

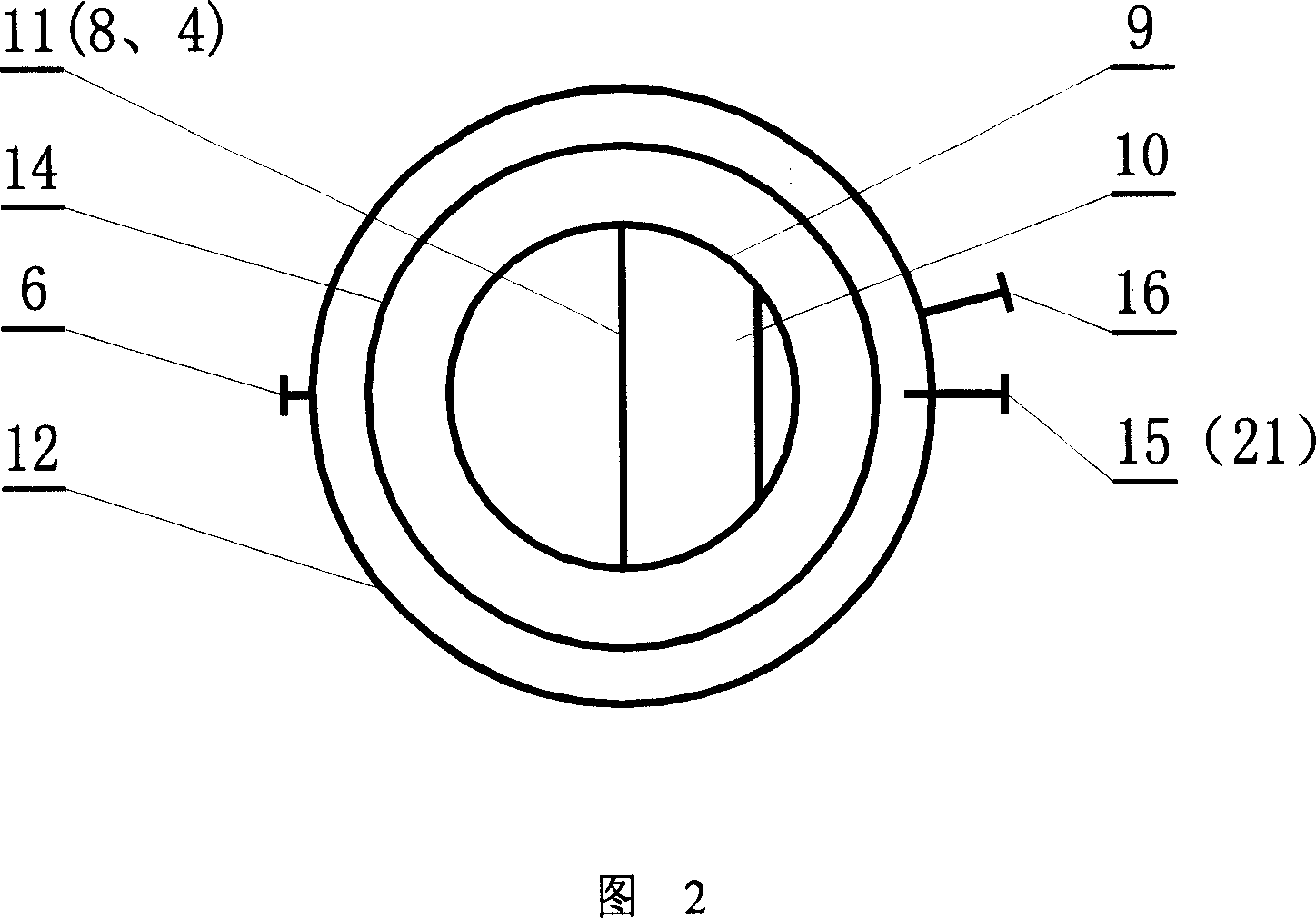

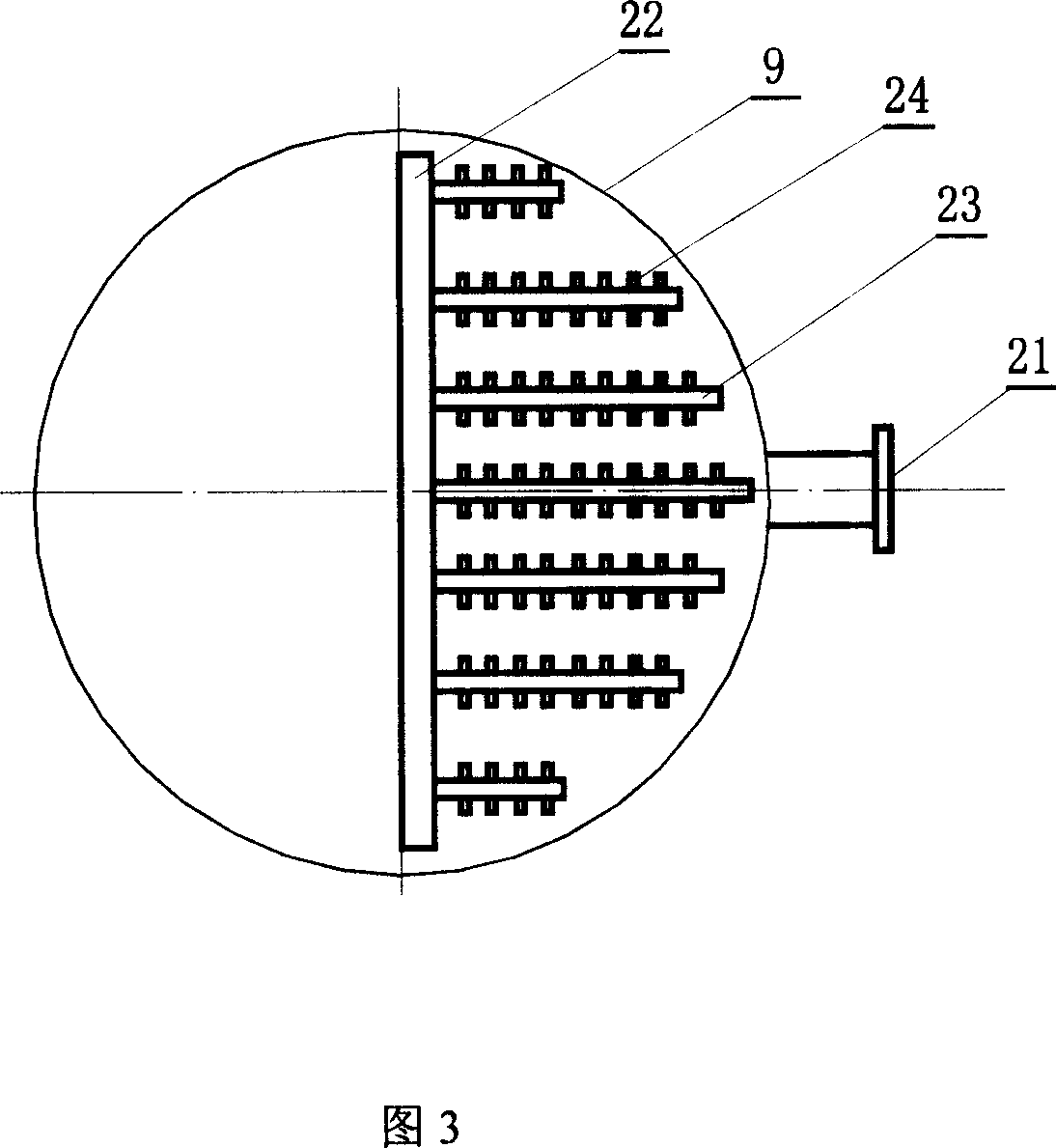

[0025]The structure of the integrated multi-stage internal circulation nitrification-denitrification biological denitrification fluidized bed reactor of this embodiment is shown in Figure 1 , Figure 2 , Figure 3 and Figure 4 . The multi-stage internal circulation nitrification-denitrification biological denitrification fluidized bed reactor in this embodiment has an integrated structure, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com