Plastic ball valve

A plastic ball valve and plastic valve technology, applied in the field of plastic ball valves, can solve the problems of increased motion friction, large valve ball holding force, difficult valve core rotation, etc., and achieve the effect of reducing the contact area and reducing the motion friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

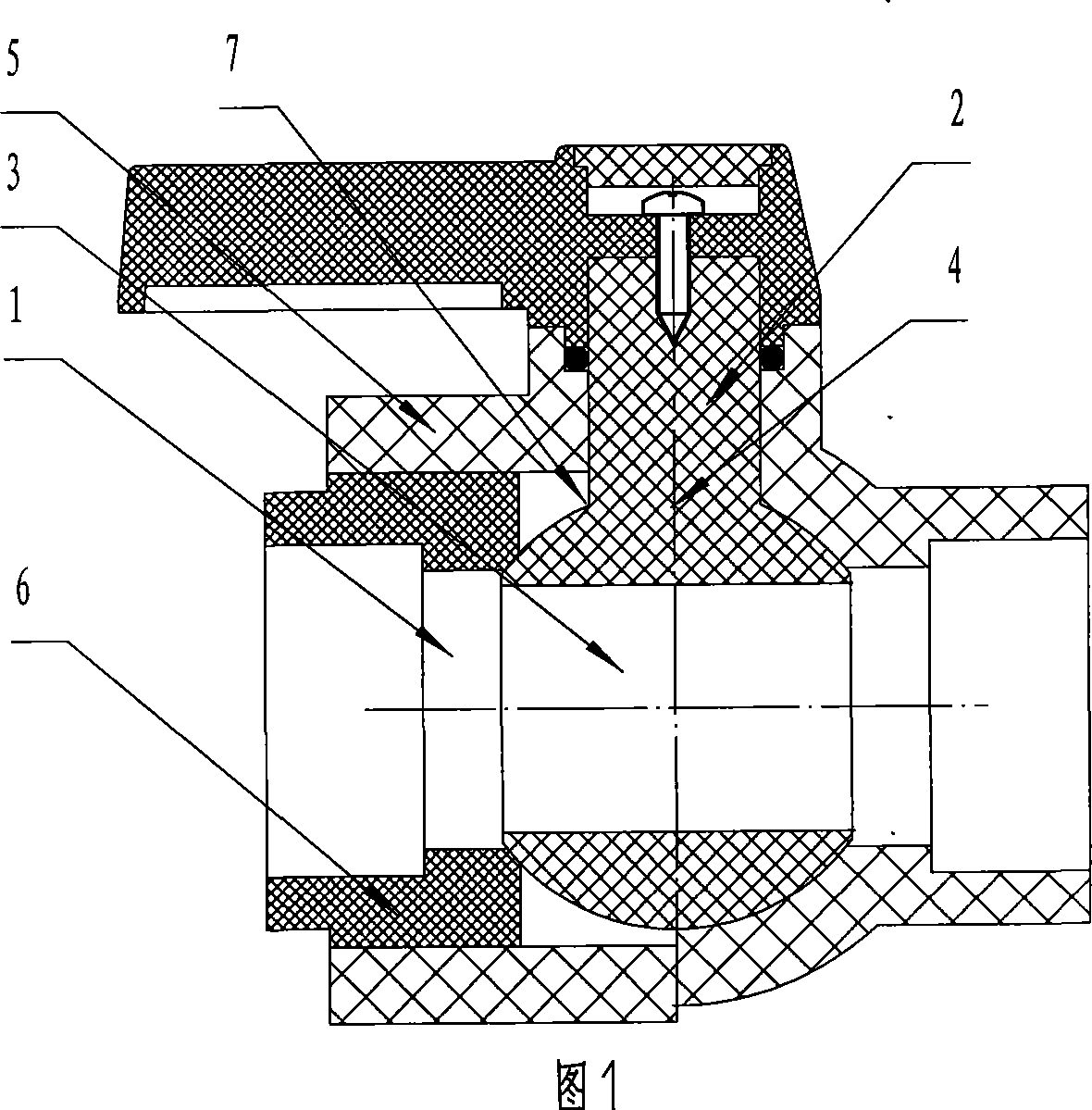

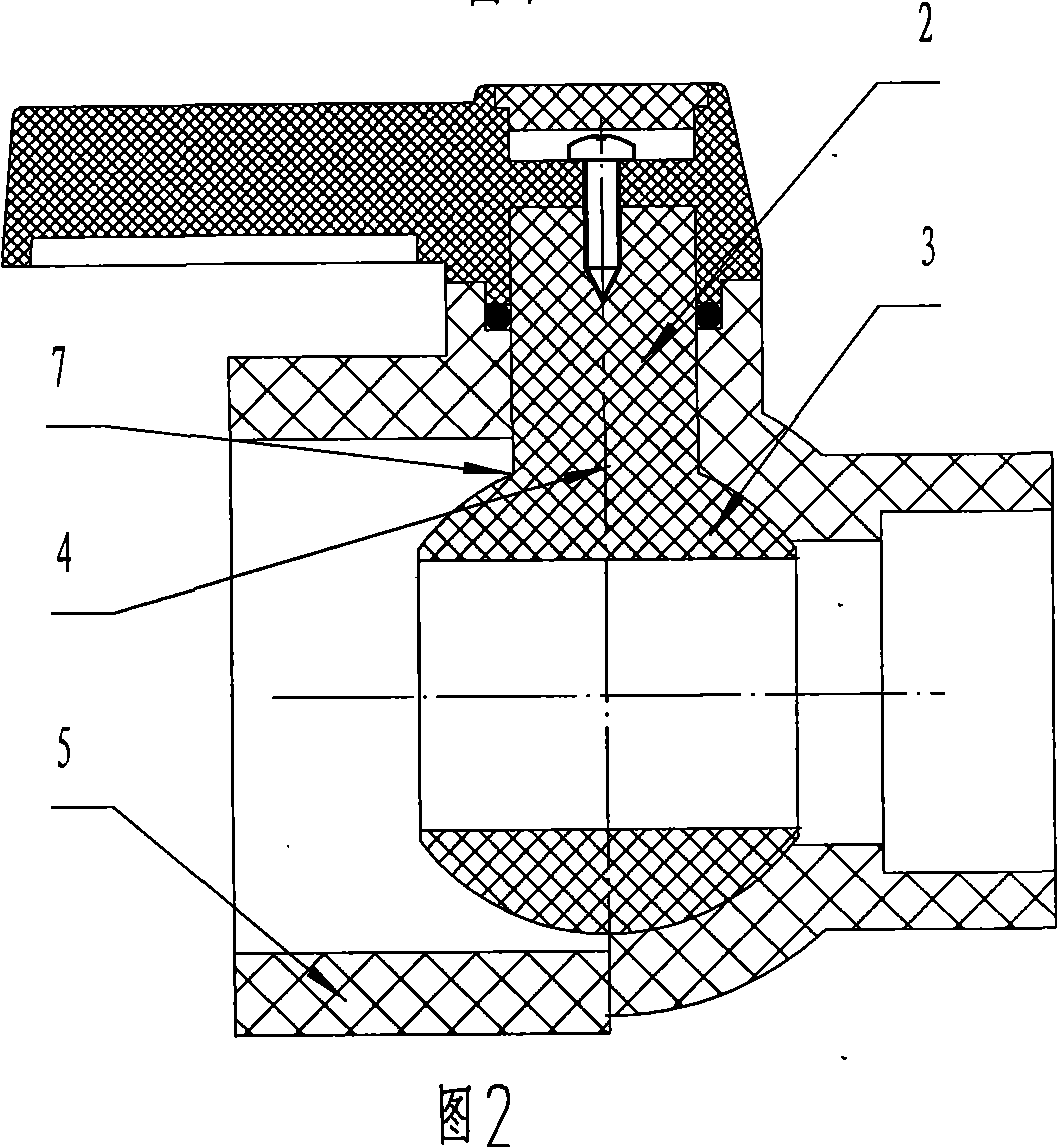

[0062] Embodiment 1: As shown in Figures 1-2, the plastic ball valve of this embodiment includes a valve body with a flow channel inside, a valve ball seat 1, and an integrated valve core 4 in which the valve stem 2 and the valve ball 3 are pre-connected as one. The valve ball 3 of the integrated spool is located in the valve body, the valve stem 2 of the integrated spool passes through the valve body, and the valve ball seat 1 is compatible with the valve ball 3 of the integrated spool, which is characterized in that : the valve body is a plastic valve body 5, and is provided with a plastic valve cover 6 with a through hole, the plastic valve cover 6 is bonded to the plastic valve body 5, and the through hole of the plastic valve cover 6 is bonded to the plastic valve cover 6 The flow passages in the valve body 5 are connected.

[0063] In this embodiment, the bonding between the plastic valve cover 6 and the plastic valve body 5 is hot-melt socket bonding.

[0064] The valv...

Embodiment 2

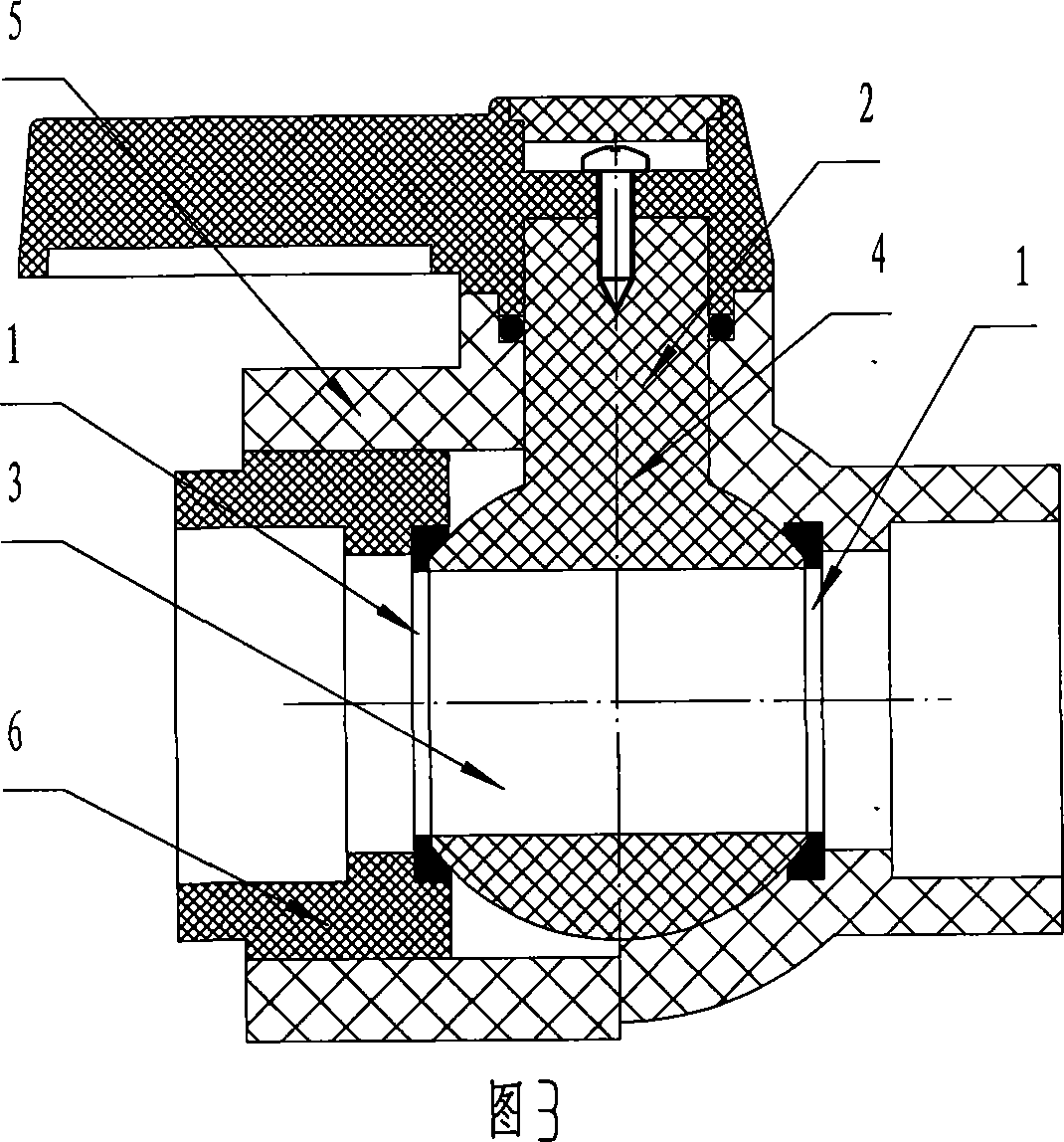

[0065] Embodiment 2: As shown in Figures 3-4, this embodiment is similar to Embodiment 1, the difference is that the plastic valve cover 6 has an annular sealing surface adapted to the spherical surface of the valve ball 3 of the integrated valve core , the annular sealing surface and the spherical surface of the valve ball 3 of the integrated valve core form a sealing pair. The annular sealing surface in this embodiment itself acts as a valve ball seat 1, that is, the annular sealing surface is a valve ball seat 1 provided separately, and there are two valve ball seats 1, and the two valve ball seats 1 are respectively provided On both sides of the valve ball 3 of the integrated valve core, in this embodiment, one of the valve ball seats 1 is located on the plastic valve cover 6 .

[0066] The plastic valve body 5 in this embodiment is a plastic valve body made of polyethylene material.

Embodiment 3

[0067] Embodiment 3: As shown in FIGS. 5-6 , this embodiment is similar to Embodiment 2, except that the valve ball seat 1 is one, and the valve ball seat 1 is located on the plastic valve cover 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com