Kitchen oil smoke pressurization and separation purifier

A purifier and oil fume technology, which is applied in the fields of oil fume removal, household heating, lighting and heating equipment, etc., can solve the problems of high operating costs, popularization, complicated operation and management, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

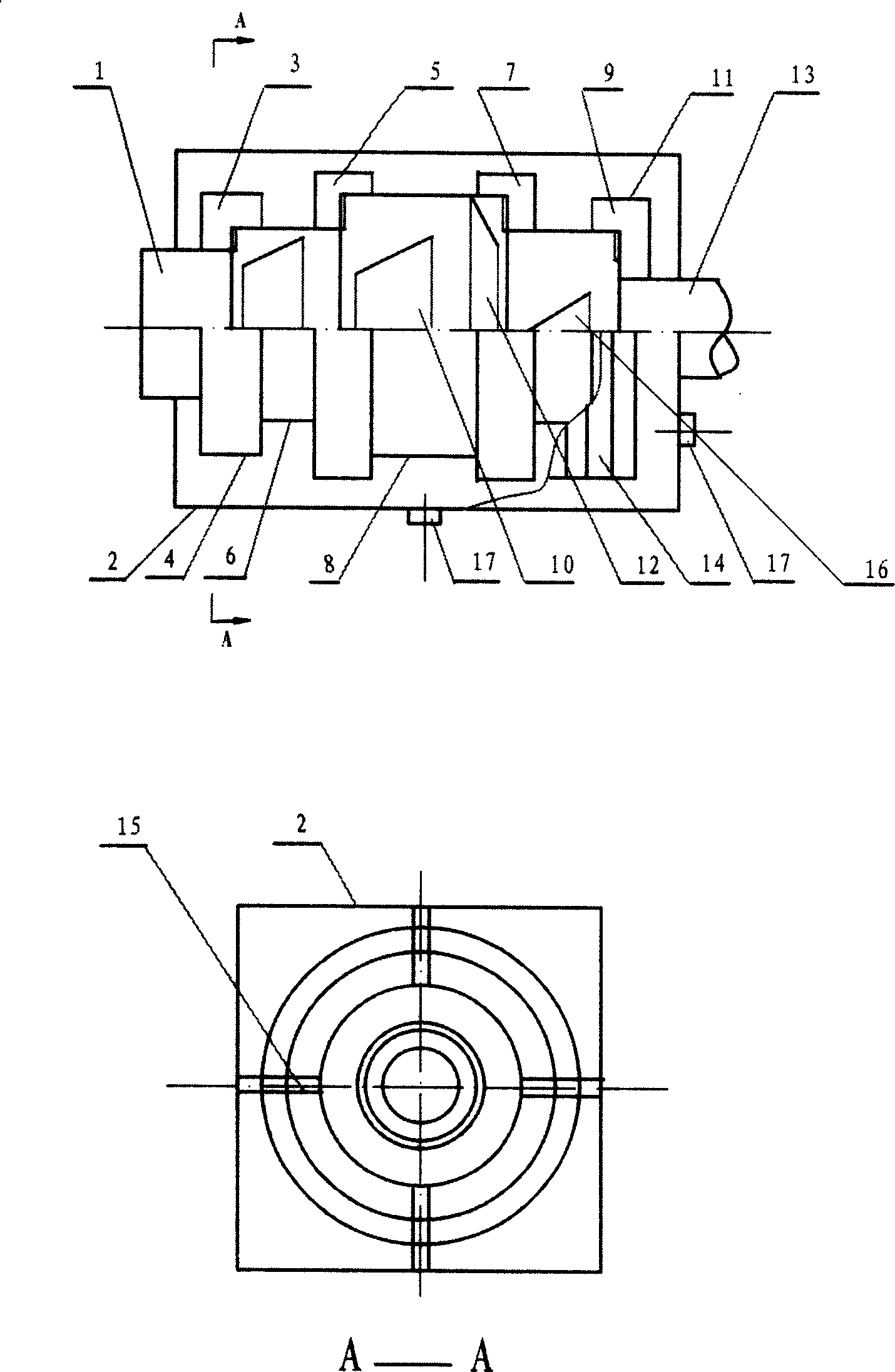

[0008] The cooking oil fume purifier designed by the present invention is composed of the air inlet 1 closely connected with the dining air outlet, and the shell 2 is to protect the purifier from weather interference, and at the same time it has the function of storing residual oil. Valve 17 is used to discharge residual oil. Clean room 3, clean room 5, clean room 7, and clean room 9 are the fume mixed gas discharged from catering after being separated by the separation sheet to be purified in the clean room respectively. The annular cover 4, annular The cylinder 6 and the middle annular cylinder 8 are fixed separation pieces. Several separation pieces 10 separate the cooking oil fume mixture into the purifier in layers. The annular cover 11 forms a clean room with the annular cylinder 6. The wind deflector 12 will The mixed gas of catering fume entering the tail of the purifier is redistributed and separated. The air outlet 13 is the exhaust port of the purified gas. The end s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com