Automatic shift current mirror

A technology of automatic shifting and current mirror, applied in the field of current mirror, which can solve the problems of large error, limited output current adjustment range, poor uniformity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The invention provides a current mirror connected in series with more than two stages, by adjusting the magnification of the front and rear two-stage current mirrors, the bias current is changed to reduce the error, just like the shifting of the mechanical gear ratio, so it is called automatic Shift current mirror.

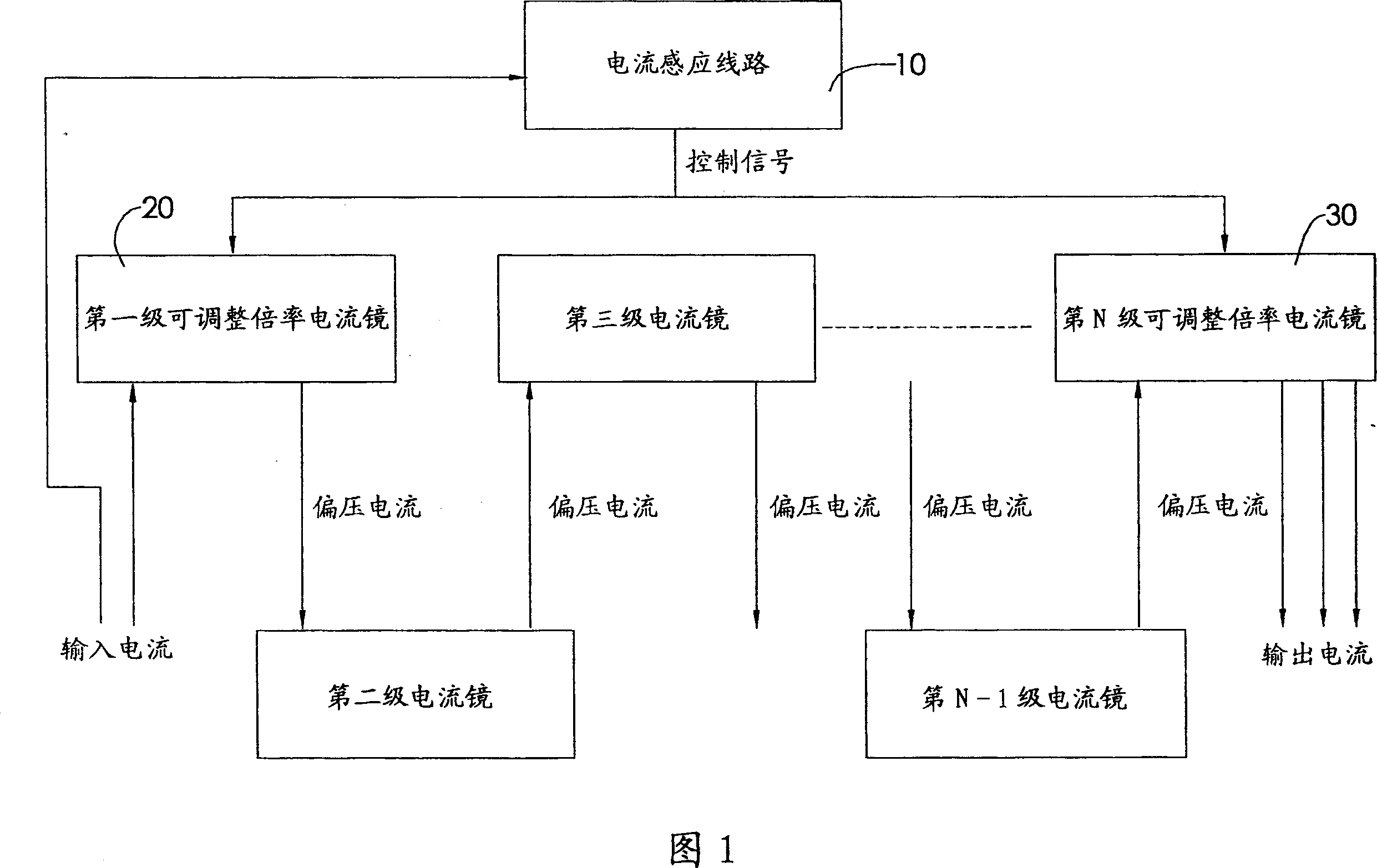

[0038] Please refer to Figure 1, the circuit architecture of the present invention mainly includes:

[0039] A pre-stage adjustable magnification current mirror 20, which establishes a bias current according to an input current;

[0040] A rear-stage adjustable-magnification current mirror 30 can be directly connected in series with the previous-stage adjustable-magnification current mirror 20, or any number of various intermediate-level current mirrors can be connected in series between the two. When there is an intermediate-level current mirror , each intermediate stage current mirror can have a plurality of output currents and a plurality of subsequent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com