Plane carbon commutator and its manufacture method

A commutator and planar carbon technology, which is applied in the field of commutators, can solve the problems of the influence of the base strength of the insulating phenolic plastic, the high requirements for the cooperation between the carbon sheet and the copper skeleton, and the troublesome processing of the carbon sheet. High, simple structure, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to better describe the present invention, the present invention will be illustrated below in conjunction with the accompanying drawings.

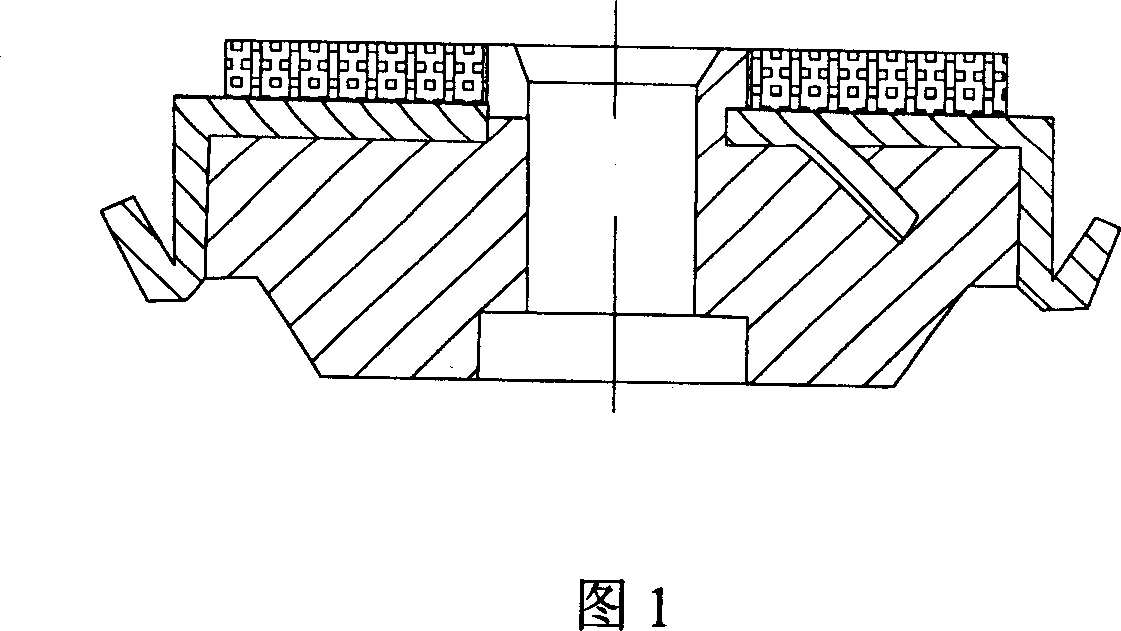

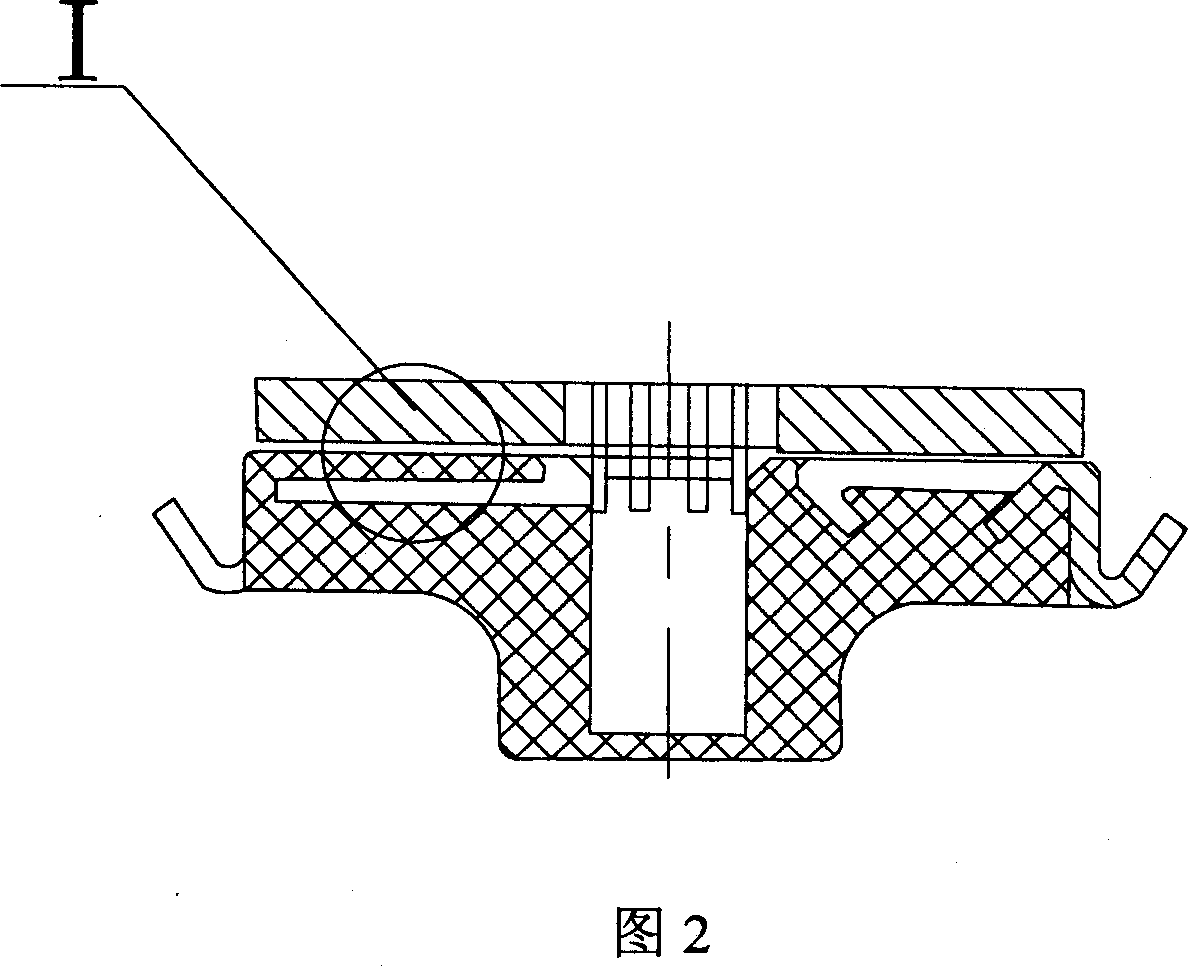

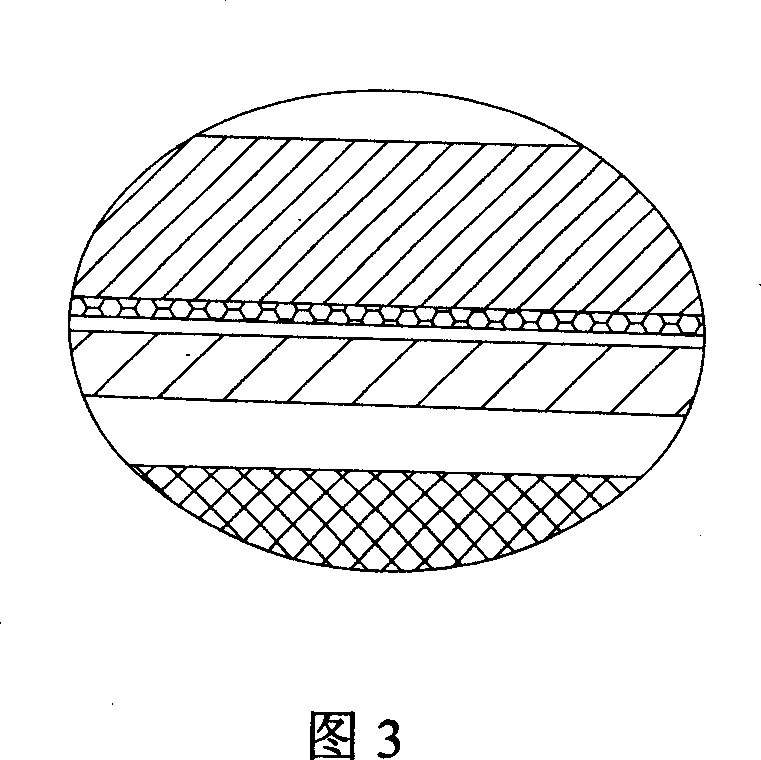

[0054] As shown in Figure 10, the planar carbon commutator comprises an insulating plastic carrier 1, the insulating plastic carrier 1 has a commutation shaft 11, the insulating plastic carrier 1 has an extended end 12 extending at least partly laterally, and eight Recess 13 on the end 12; eight copper conductor parts 2 arranged around the reversing shaft 11 are fixed to the insulating plastic carrier 1 and combined with the extended end 12 of the insulating plastic carrier 1 without gaps, and with the copper conductor parts 2 The same number of carbon parts 3 are riveted and electrically conductively connected to these copper conductor parts 2, and the carbon parts 3 are likewise bonded to the insulating plastic carrier 1 without gaps.

[0055] Each carbon made part 3 has a carbon brush contact surface 31, on the back face ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com