Blanks for gray tone mask, gray tone mask using said blanks, and process for producing said blanks

A grayscale mask and a manufacturing method technology, which are applied in the photoengraving process of the pattern surface, the original for optical mechanical processing, optics, etc. and other problems, to achieve the effects of reduced manufacturing cost, good processability, and good pattern shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

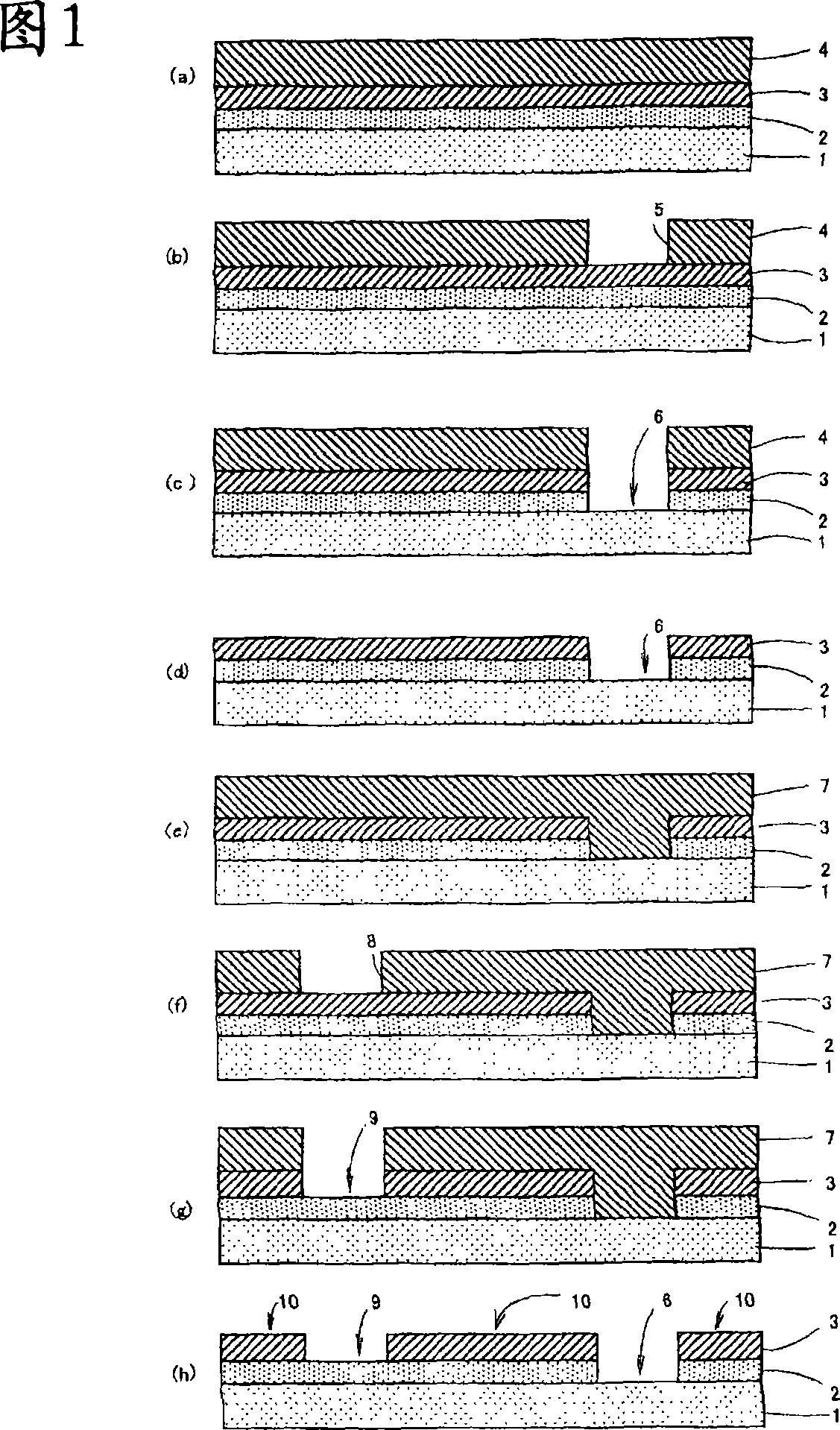

Method used

Image

Examples

Embodiment 1

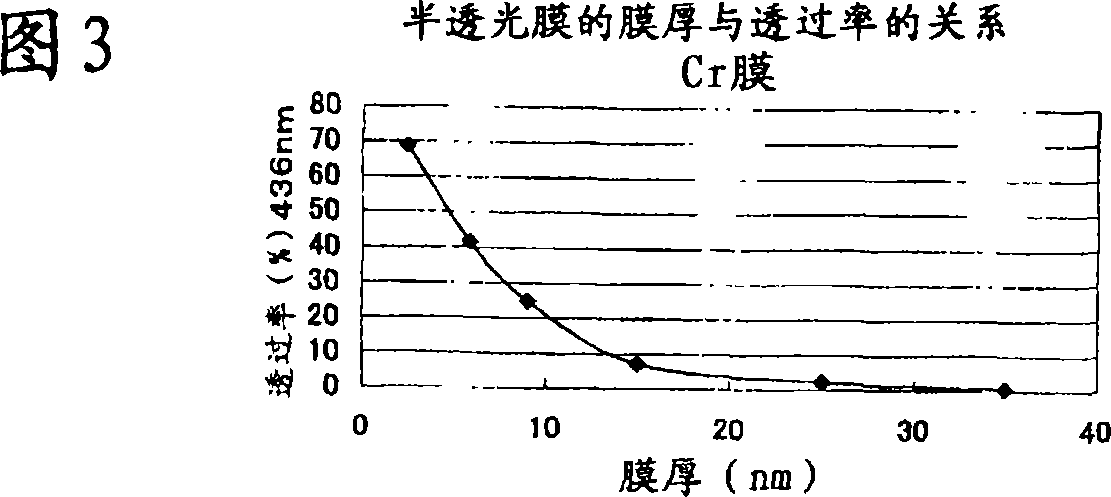

[0112] Use on transparent substrates containing NiMo18 atomic % and Ti27 atomic %, NiMo21 atomic % and Ti17 atomic %, NiMo22 atomic % and Ti15 atomic %, NiMo22 atomic % and Ti12 atomic %, NiMo18 atomic % and Ti12 atomic %, NiMo23 atomic % And Ti10 atomic %, NiMo23 atomic % and Ti9 atomic %, NiMo15 atomic % and Al20 atomic %, NiMo25 atomic %, NiMo7 atomic % sintered body target, and pure Cr target, in a vacuum chamber with a specified atmosphere gas, through direct current A light-shielding film and a light-transmitting film are formed by sputtering.

[0113] The transparent substrate uses a quartz plate with a thickness of 5.0mm or a blue plate glass with a thickness of 4.8mm. During film formation, the transparent substrate is heated by a quartz heater installed in a vacuum chamber to reach a temperature of 120-200°C. In the vacuum chamber, as the atmosphere gas, only Ar gas is used to fabricate metal NiMoTi film, metal NiMoAl film, metal NiMo film, and metal Cr film. In addi...

Embodiment 2

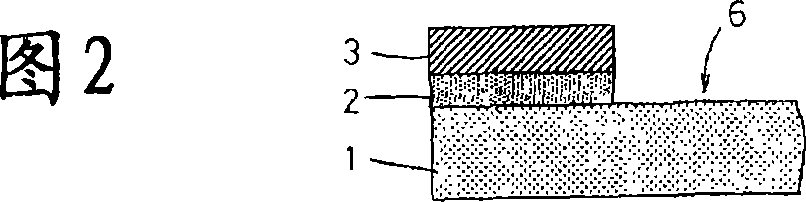

[0122] Based on the results obtained in Example 1, a grayscale mask was actually fabricated. As the film composition, as shown in Table 2, under the same film-forming conditions as in Example 1, a two-layer film of the following composition was produced: the light-shielding film was a NiMo22Ti15 film, and the semi-transparent film was a Cr film (NO.18). The film composition of the grayscale mask blank, the light-shielding film is NiMo22Ti15 film, the semi-transparent film is CrOx film (NO.19) The film composition of the gray-scale mask blank, the light-shielding film is NiMo15Al20 film, the semi-transparent film is CrOx film (NO.21) gray-scale mask blank film composition, the light-shielding film is a NiMo25 film, the semi-transparent film is a film composition of a gray-scale mask blank CrOx film (NO.22); further as a Cr element-free The film composition of the gray scale mask blank, the light-shielding film is NiMo22Ti15 film, the semi-transparent film is NiMo15Al20 film (NO...

Embodiment 3

[0127] An anti-reflection film was formed on the light-shielding film of grayscale mask blank No. 19 in Example 2 to prepare grayscale mask blank No. 20. The film formation conditions and the etching process for the grayscale mask were performed under the same conditions as in Example 2. Anti-reflective coating using Ar gas and CO 2 The gas is formed by the reactive sputtering method, and the film formation on the light-shielding film and the anti-reflection film is performed by the same film forming machine at one time. Table 2 shows the results of measuring the reflectance on the film surface side of the obtained gray scale mask blank. In addition, the transmittance after film formation of the semi-transparent film was measured, the measurement of the optical density OD of the two-layer film after film formation, the cross-sectional shape of the opening after patterning using the first etchant, and the use of The measurement of the transmittance of the semi-transparent por...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com