Shoulder joint cavema side prosthesis

A shoulder joint and prosthesis technology, applied in the field of glenoid prosthesis of the shoulder joint, can solve the problems of unstable fixation, large randomness, and no uniform standard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

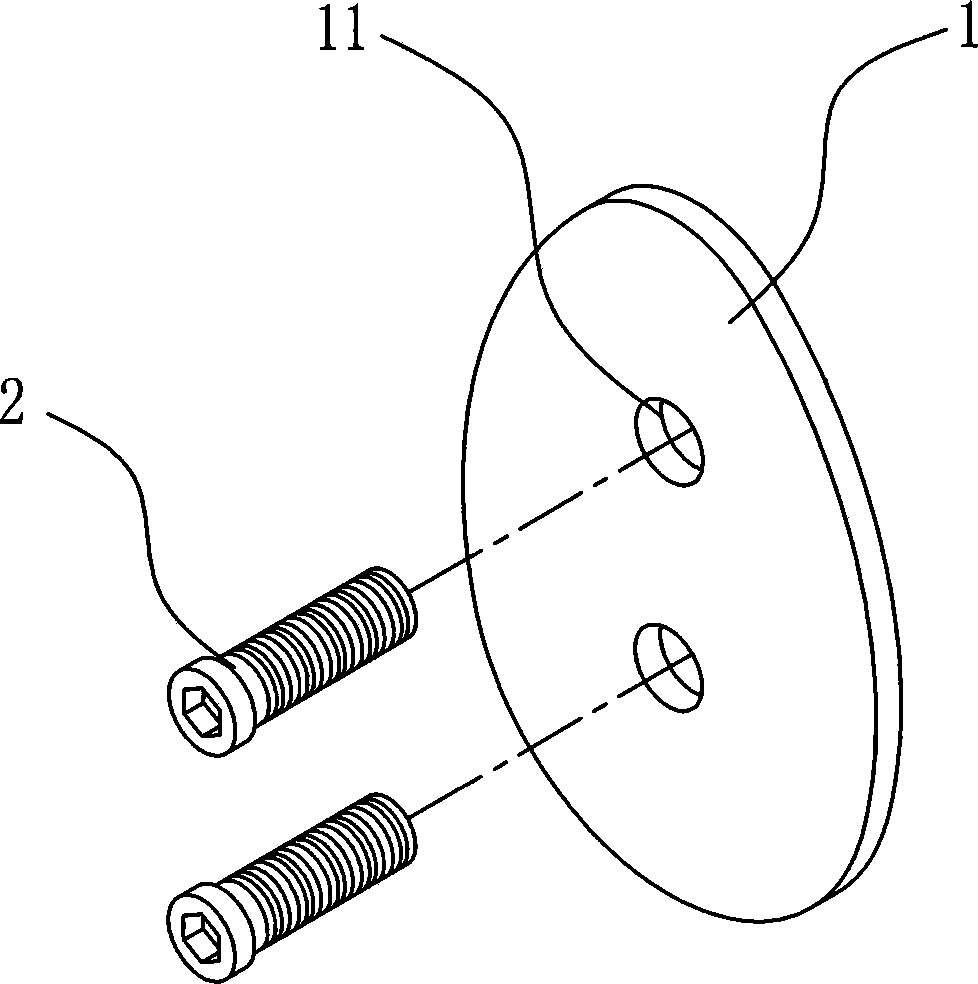

[0016] Please refer to Figures 1 to 3 As shown, a shoulder glenoid prosthesis, the profile of the prosthesis 1 is shaped like a kidney, and the prosthesis 1 is provided with screw holes 11 for fixing the screws 2; the screw holes 11 are respectively arranged in the prosthesis 1 The upper and lower thirds of the surface.

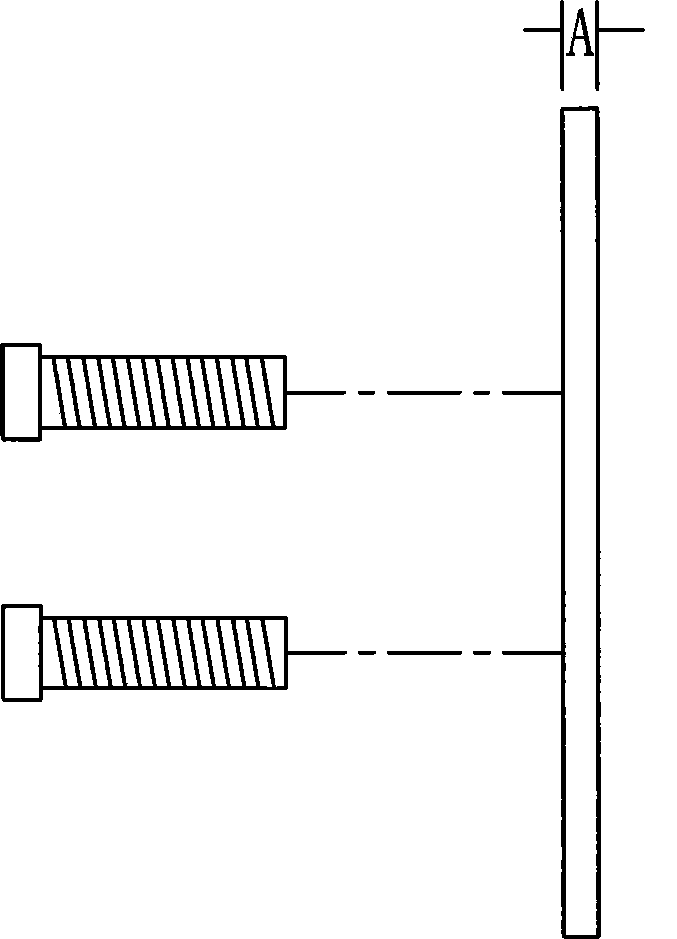

[0017] The thin layer thickness A of the prosthesis 1 is less than 5mm.

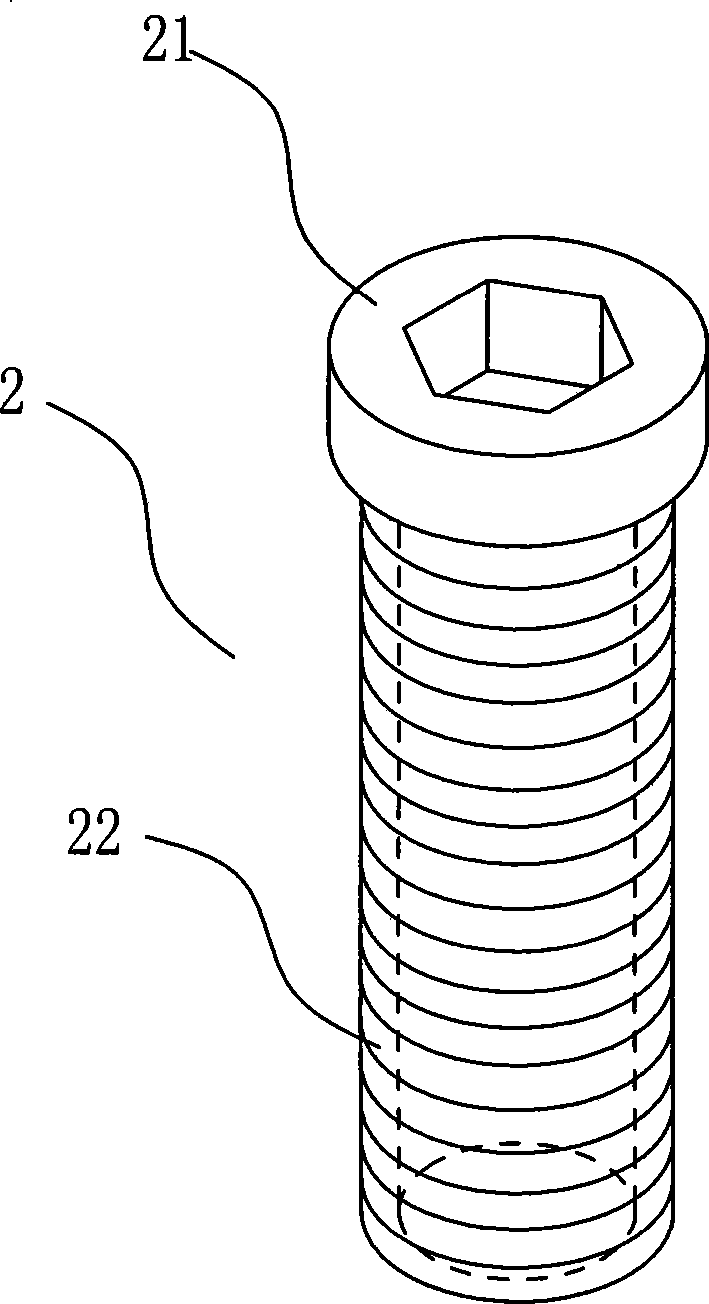

[0018] refer to image 3 As shown, the screw 2 is a double niche screw, the so-called niche screw 2, that is, its screw 2 is a hollow design; the screw 2 is divided into two parts, a nail cap 21 and a nail body 22, and the inner core of the nail cap 21 of the screw 2 is The inner hexagonal shape design provides the focus point for screwing the scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com