Paint booth

A painting room and painting technology, which is applied in the field of painting rooms, can solve problems such as constraints, low efficiency of painting operations, and increase of painting costs, so as to shorten the time of painting operations, improve the efficiency of painting operations, and reduce the The effect of the paint booth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] Next, a painting booth according to an embodiment of the present invention will be described with reference to the drawings.

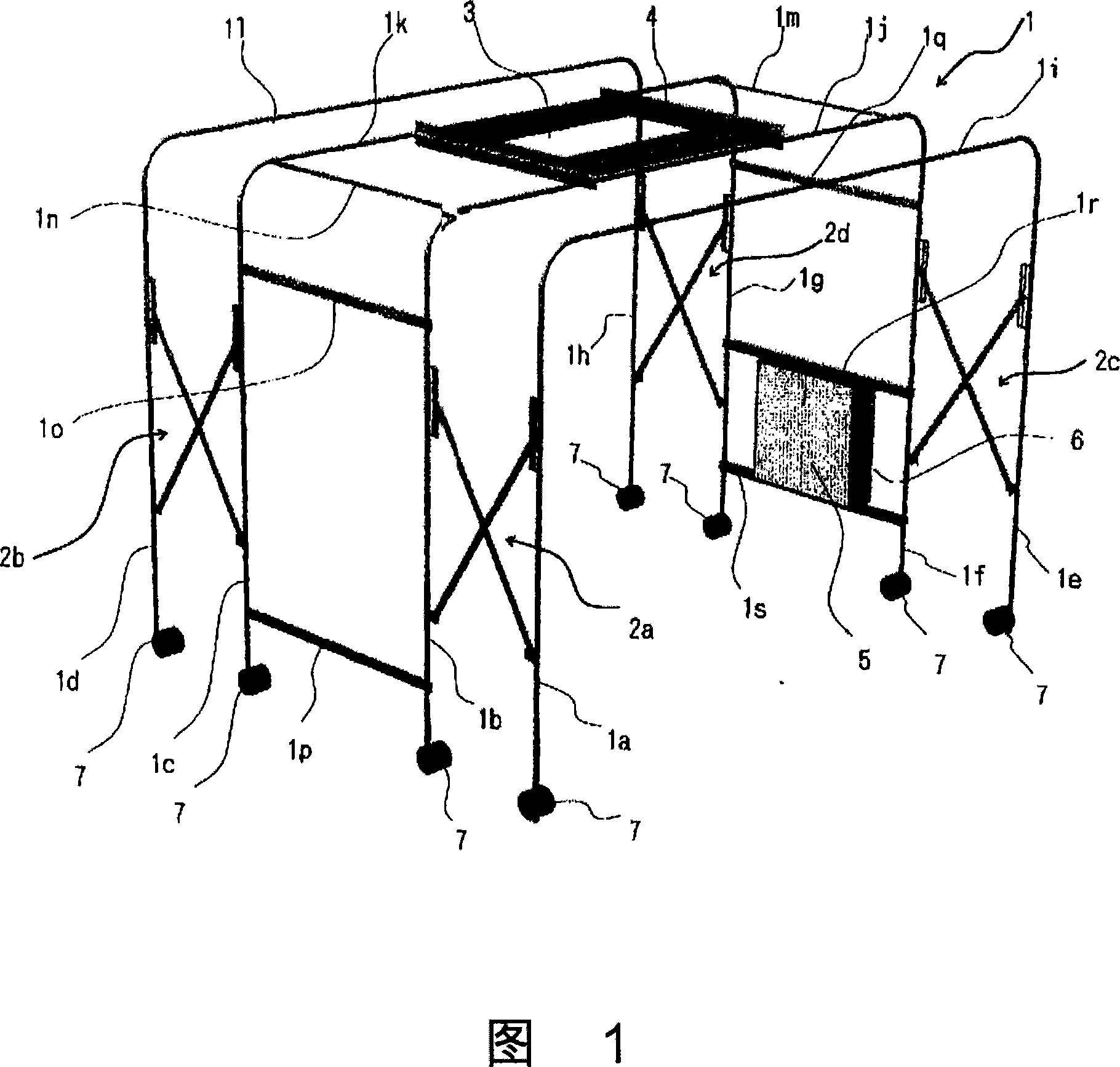

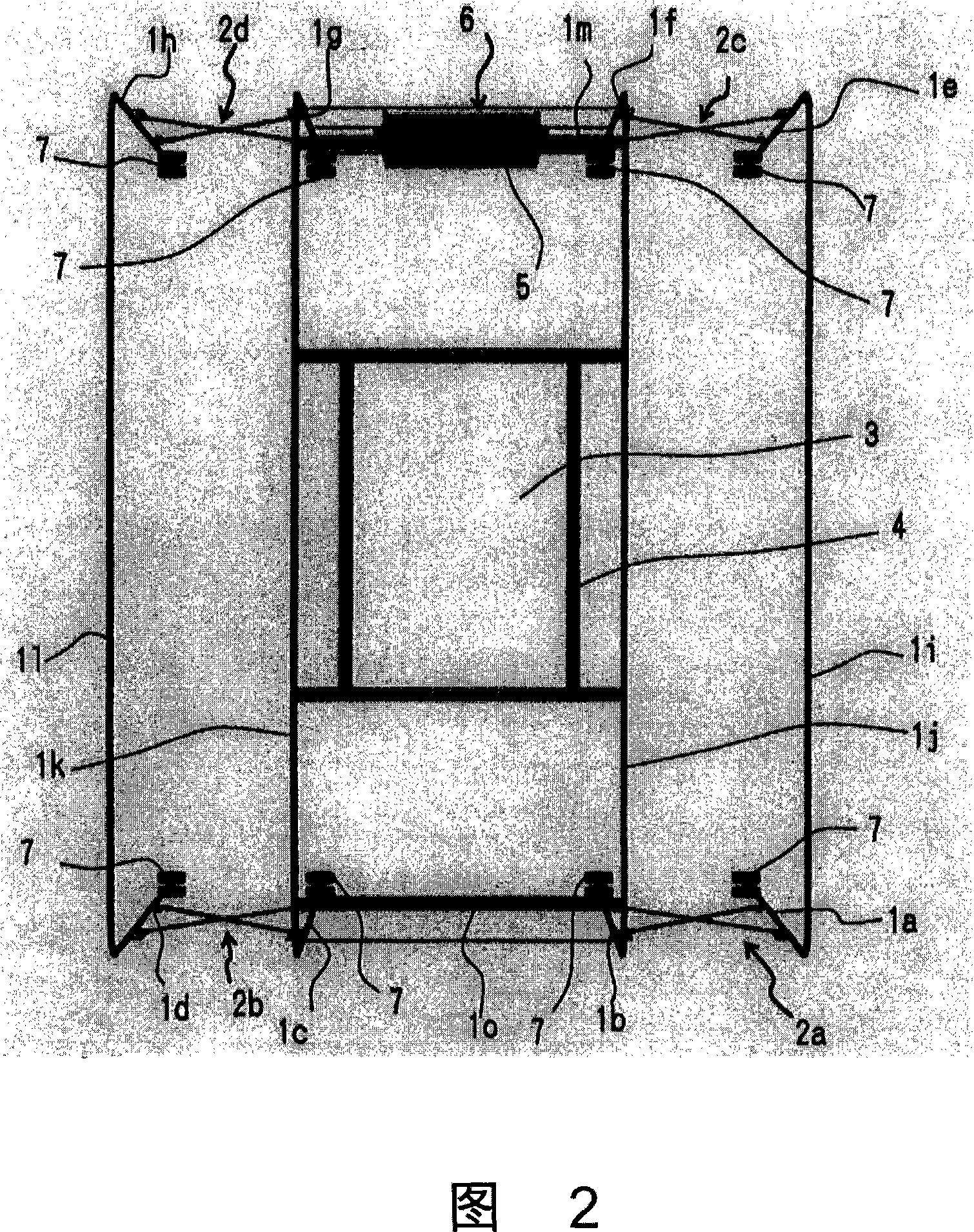

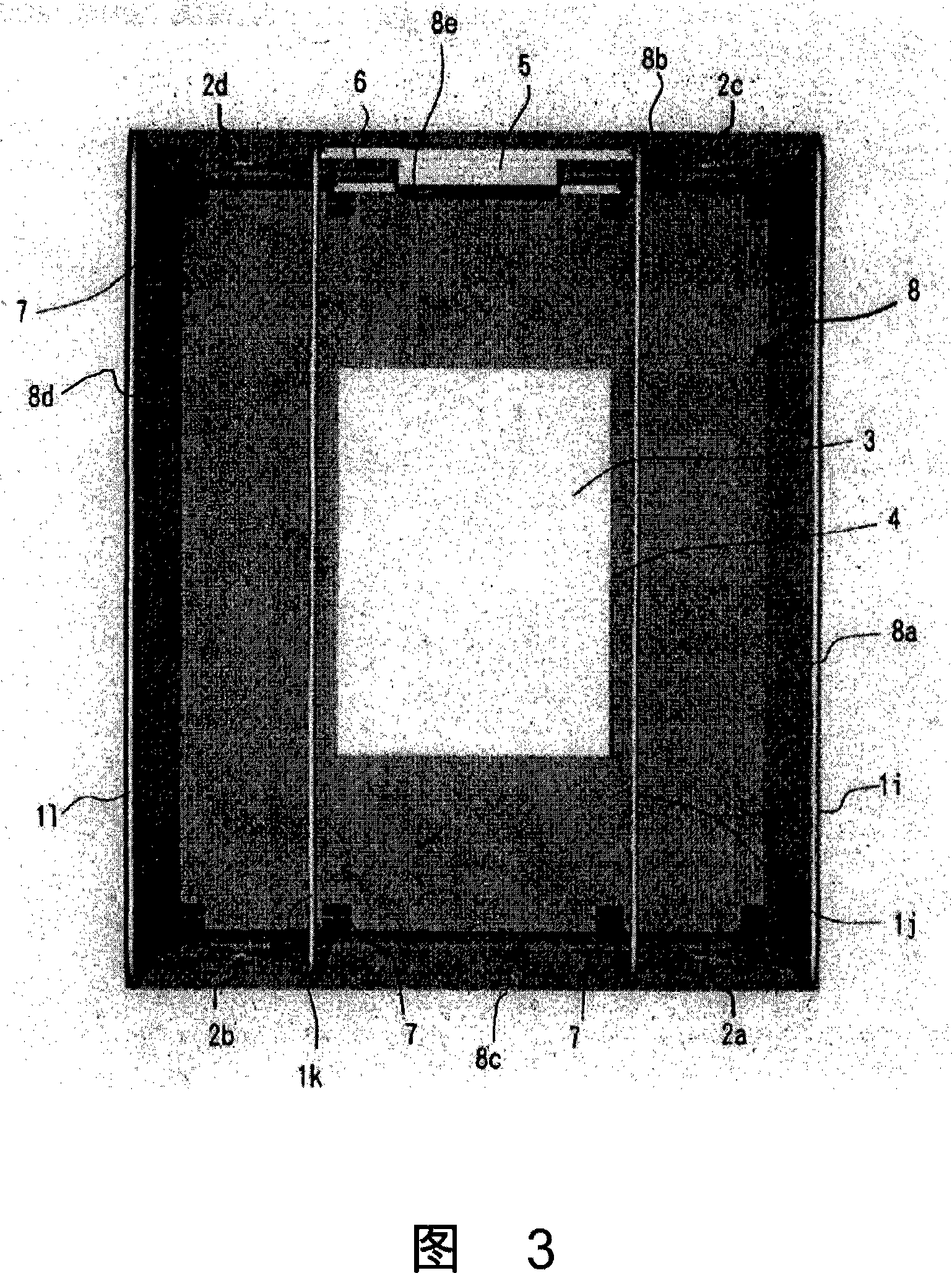

[0064] Fig. 1 is a schematic structural perspective view of the frame group member of the first embodiment of the painting booth according to the present invention seen obliquely from above, and Fig. 2 is a frame group of the painting booth shown in Fig. 1 seen from directly above A three-dimensional view of a model structure of a component, etc.

[0065] In Fig. 1 and Fig. 2, the skeleton group member 1 forms a roughly cuboid painting space as a whole, including: left and right four vertical frames 1a, 1b, 1c, 1d and 1e, 1f, 1g, 1h; top frames 1i, ij, 1k, 1l, 1m, 1n; horizontal frame 1o, 1p, 1q, 1r, 1s; zoom mechanism 2a, 2b and 2c, 2d.

[0066] In Fig. 1 and Fig. 2, the vertical frames 1a-1d, the top frames 1i-1l and the vertical frames 1e-1g are respectively integrally formed, but they can also be made into separate components and combined b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com