Cracking furnace with radiation furnace tubes configured in U-shaped structure

A radiant furnace tube and cracking furnace technology, which is applied in the direction of hydrocarbon cracking, hydrocarbon production, organic chemistry, etc., can solve the problems affecting the circumferential temperature distribution of the furnace tube, etc., and achieve the effects of uniform force, large production capacity, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] Provide an embodiment below in conjunction with accompanying drawing 47. The following descriptions only represent specific embodiments of the present invention, and are only used to further illustrate the present invention, but not to limit the present invention.

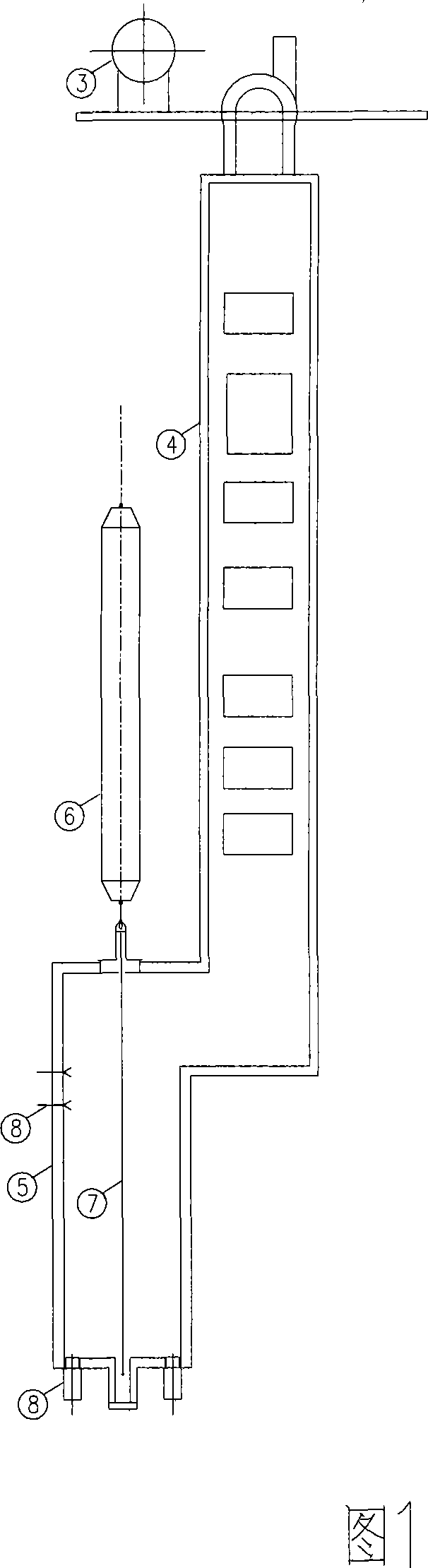

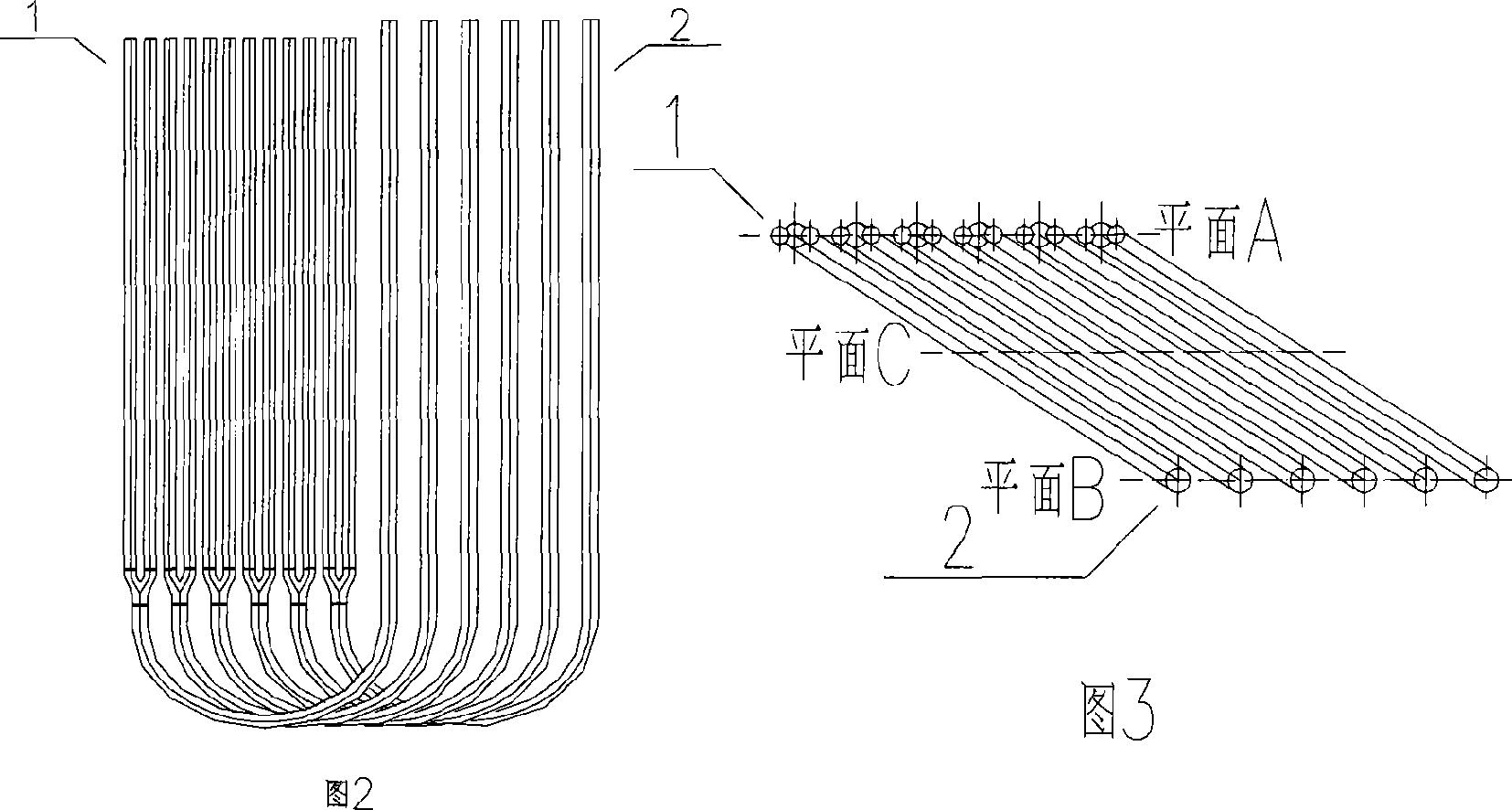

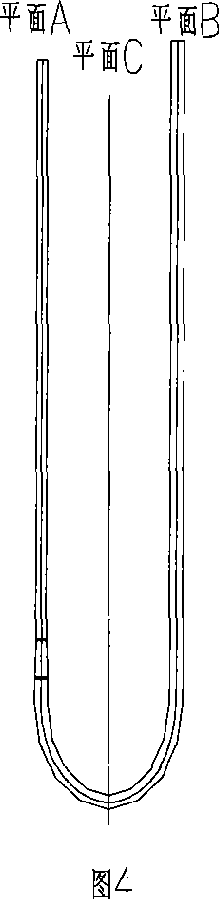

[0074] The cracking furnace of the present invention comprises a high-pressure gas bag 3, a convection section 4, a radiation section 5, a plurality of groups of radiation furnace tubes 7, a burner 8, and a quench boiler 6 vertically arranged in the radiation section; Length 14000mm. Each two-pass vertical radiation furnace tube arranged in a 2-1 pattern is composed of the first-pass tube 1 and the second-pass tube 2, and the first-pass tube and the second-pass tube are connected by a semicircular elbow connector; The pyrolysis material is introduced from the first pass pipe and drawn out from the second pass pipe. The upper part of the first pass pipe is two inlet pipes, which are combined by a three-way ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com