Method of manufacturing semiconductor device

A manufacturing method and semiconductor technology, applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve the problems of complex bipolar transistor structure, a lot of time, and complex manufacturing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention will be described in detail below with reference to the drawings.

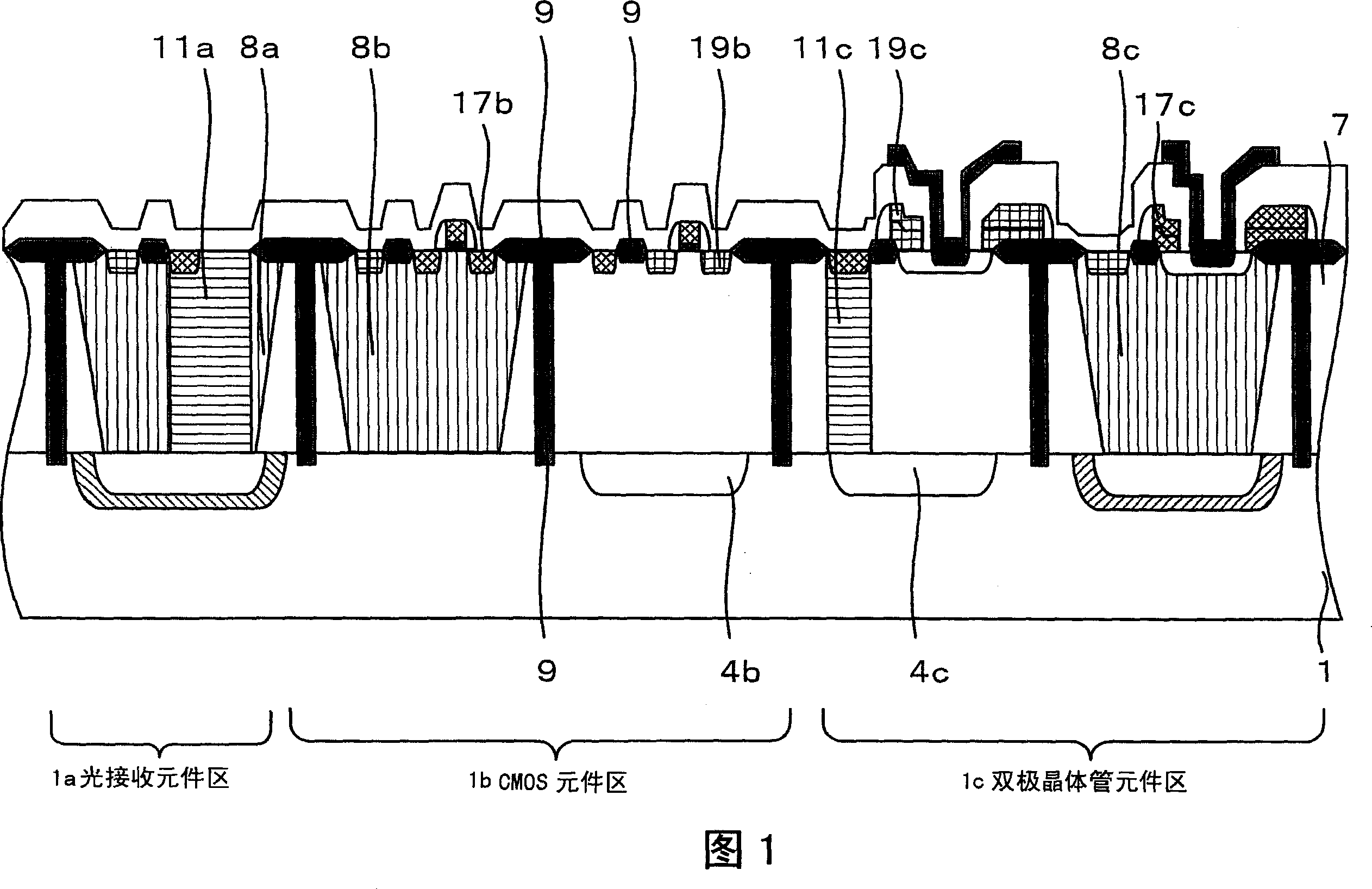

[0016] First, FIG. 1 will be briefly described.

[0017] 1 is a schematic cross-sectional view of a semiconductor device in which a light receiving element part, a CMOS element, and a bipolar transistor element having a double-layer polysilicon structure are formed on one chip.

[0018] The outline of the manufacturing method of the above-mentioned semiconductor device will be described below.

[0019] As shown in FIG. 1, the light receiving element region 1a, the CMOS element region 1b, and the bipolar transistor region 1c are provided on the semiconductor substrate 1.

[0020] First, the same N-type ion implantation is performed to simultaneously form high-concentration N-type diffusion layers 4b and 4c in the CMOS element region 1b and the bipolar transistor element region 1c of the semiconductor substrate 1.

[0021] Next, an epitaxial layer 7 is formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com