Process of producing stalk recombining material

A manufacturing method and technology of recombined wood, applied in the direction of manufacturing tools, flat products, wood processing appliances, etc., can solve the problems of destroying the longitudinal strength of straw, single structure, and few varieties, and achieve easy control of moisture content, simple production process, and sticky convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

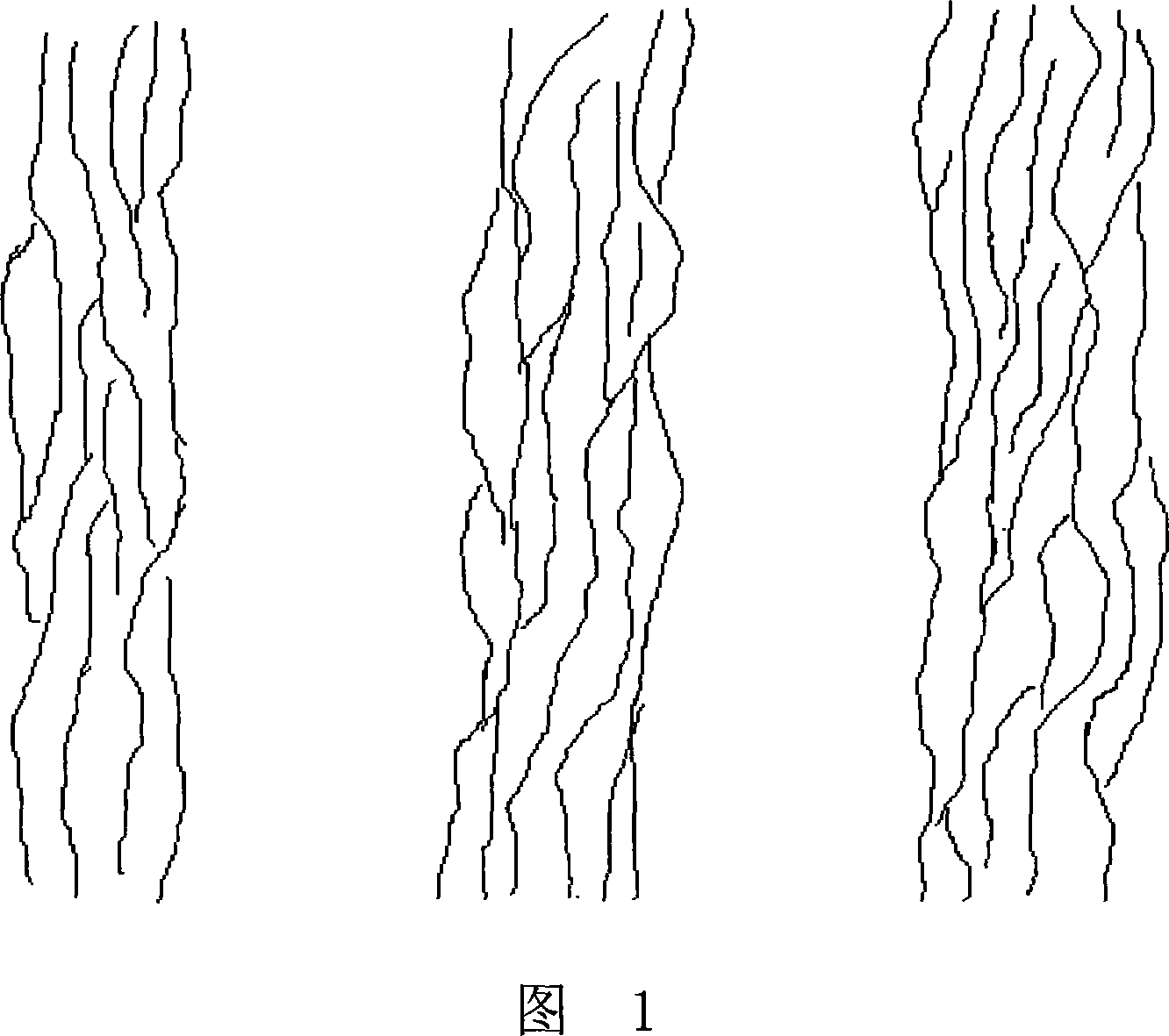

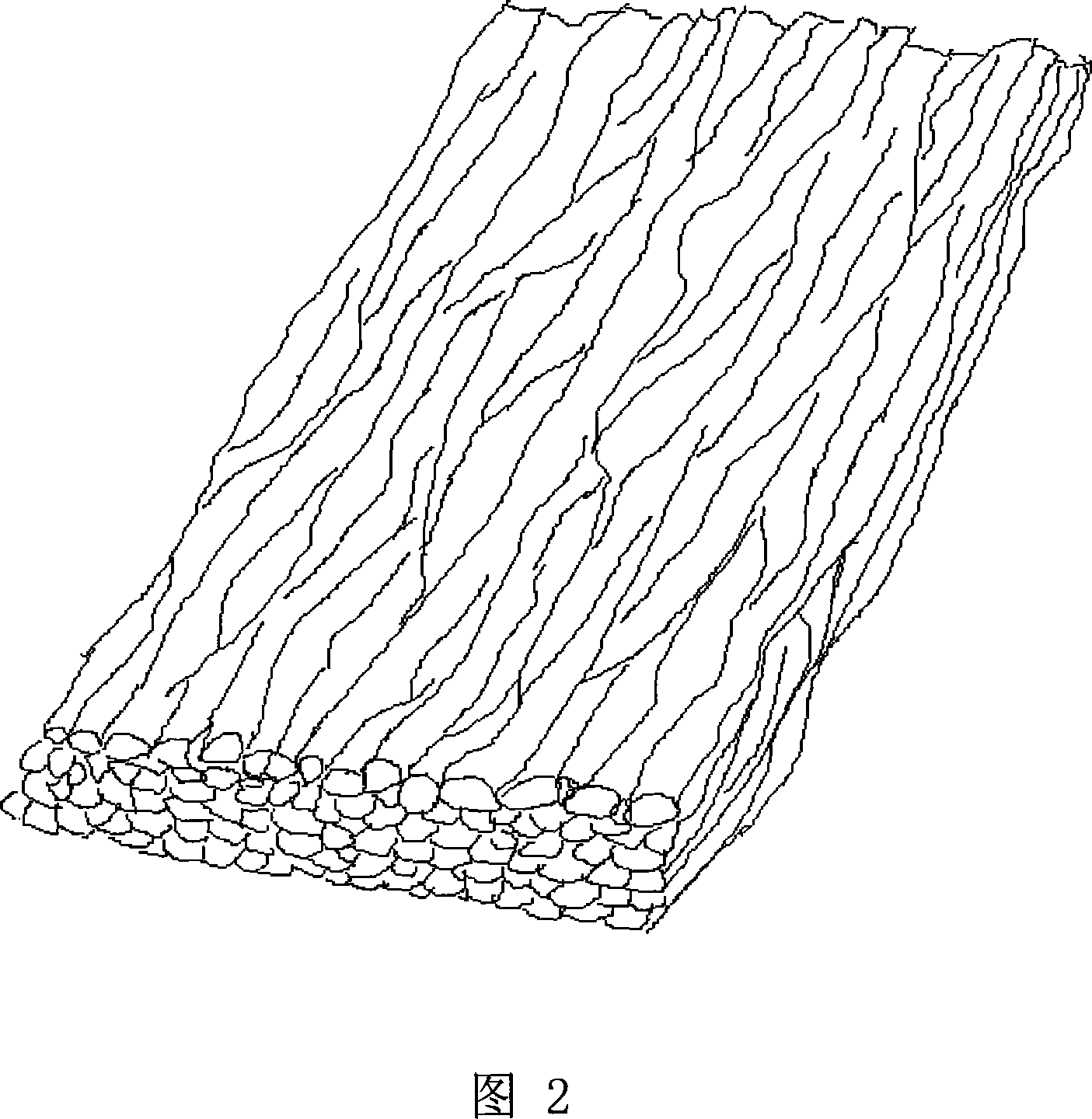

[0019] After the roots and leaves are removed from the cotton stalks, they are steamed and softened, rolled and peeled off, and then processed into cotton stalk fiber bundles that are not broken vertically and interlaced in the horizontal direction, as shown in Figure 1; the cotton stalk fiber bundles are dried to a moisture content of ≤10%. Use urea-formaldehyde resin glue with a solid content of about 50% for glue spraying treatment, and then assemble the billets, and after the glue is applied, the pavement and billets of the straw fiber bundles are arranged in the same direction, as shown in Figure 2; after pre-pressing, hot pressing, and sawing The finished product of cotton stalk recombined wood is obtained. The table below shows the comparison of the physical and mechanical properties of the cotton stalk recombined wood produced by the present invention and related materials in the prior art.

[0020] Material

example 2

[0022] After removing the roots, clips and leaves of the bean stalks, they are cooked and softened, and then rolled and processed into bean stalk fiber bundles. The bean stalk fiber bundles are dried to a water content of ≤10%, sprayed with urea-formaldehyde resin glue with a solid content of about 50%, and then formed into billets, which are pre-pressed, hot-pressed, and sawn to obtain finished bean stalk recombined wood.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com