No-lead glass powder for electrode coating and its prepn process

A lead-free glass powder and coating technology, which is applied in the field of lead-free glass powder and its preparation, can solve problems such as low image quality, and achieve the effects of simple preparation process, convenient operation, and good chemical and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

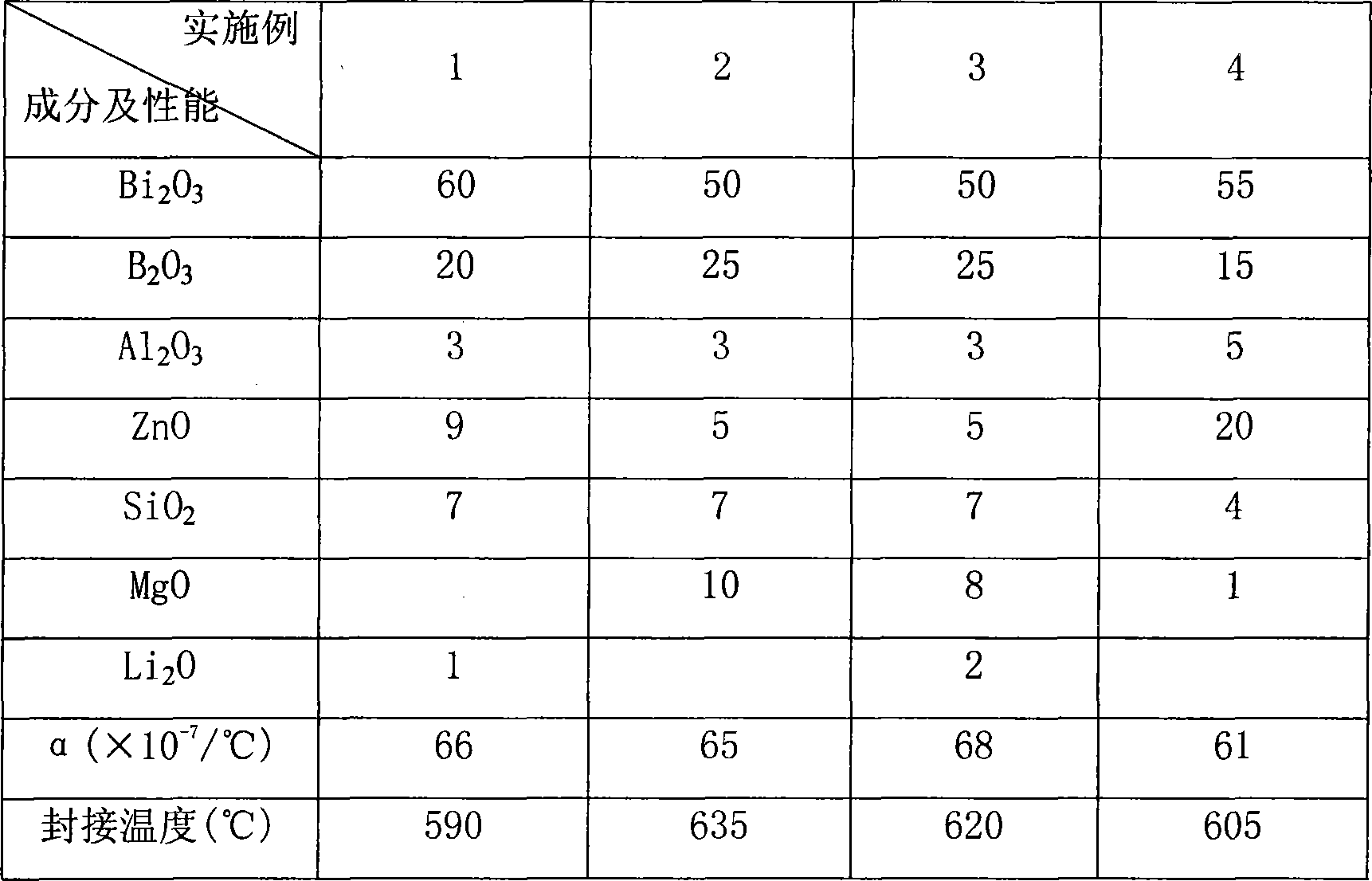

[0027] Table 1 (wt%)

[0028]

[0029] According to the weight percentage of the composition in Table 1, the ingredients were mixed evenly, the glass frit was put into a quartz crucible, and heated and melted in a silicon carbide rod electric furnace at a melting temperature of 1150°C and kept for 14 minutes.

[0030] Bi in Example 1 2 o 3 The content is relatively large, which mainly plays a role in lowering the melting temperature. There is a very small amount of scum on the surface of the glass melted without adding MgO, but it basically has no effect on the essence of the glass.

[0031] The melted glass is put into a preheated mold to be formed, and quickly placed in a muffle furnace for annealing at 450°C, kept for 1 hour and then cooled with the furnace.

[0032] The annealed sample was ground into a cylindrical sample of φ5×25mm for performance analysis. The coefficient of thermal expansion (α) was measured with a WRP-1 microcompute...

Embodiment 2

[0034] According to the weight percentage of the composition in Table 1, the ingredients are mixed evenly, the glass frit is put into a quartz crucible, and heated and melted in a silicon carbide rod electric furnace at a melting temperature of 1250 ° C and kept for 12 minutes.

[0035] The melted glass is put into a preheated mold to be formed, and quickly placed in a muffle furnace for annealing at 450°C, kept for 1 hour and then cooled with the furnace.

[0036] The annealed sample was ground into a cylindrical sample with a size of φ5×25mm for performance analysis. The test results are shown in Table 1.

Embodiment 3

[0038] According to the weight percentage of the composition in Table 1, the ingredients are mixed evenly, the glass frit is put into a quartz crucible, and heated and melted in a silicon carbon rod electric furnace at a melting temperature of 1250 ° C and kept for 12 minutes.

[0039] The melted glass is put into a preheated mold to be formed, and quickly placed in a muffle furnace for annealing at 450°C, kept for 1 hour and then cooled with the furnace.

[0040] The annealed sample was ground into a cylindrical sample with a size of φ5×25mm for performance analysis. The test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com