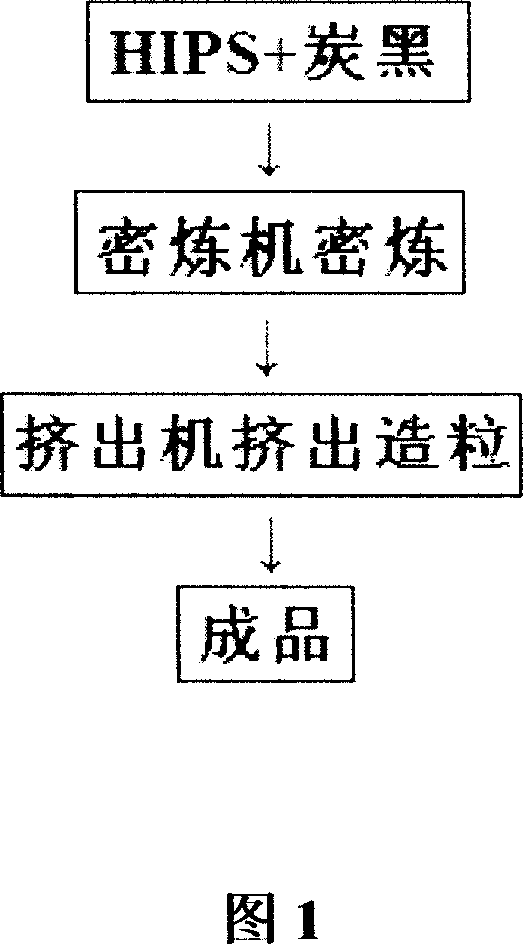

Prepn process of nanometer carbon black modified conductive plastic

A technology of conductive plastic and nano-carbon black, which is applied in the direction of conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problems of material performance being greatly affected, and achieve the effects of avoiding a large number of agglomerations, reducing stress concentration points, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment one: the preparation of the conductive plastic modified by nano-carbon black of the present invention

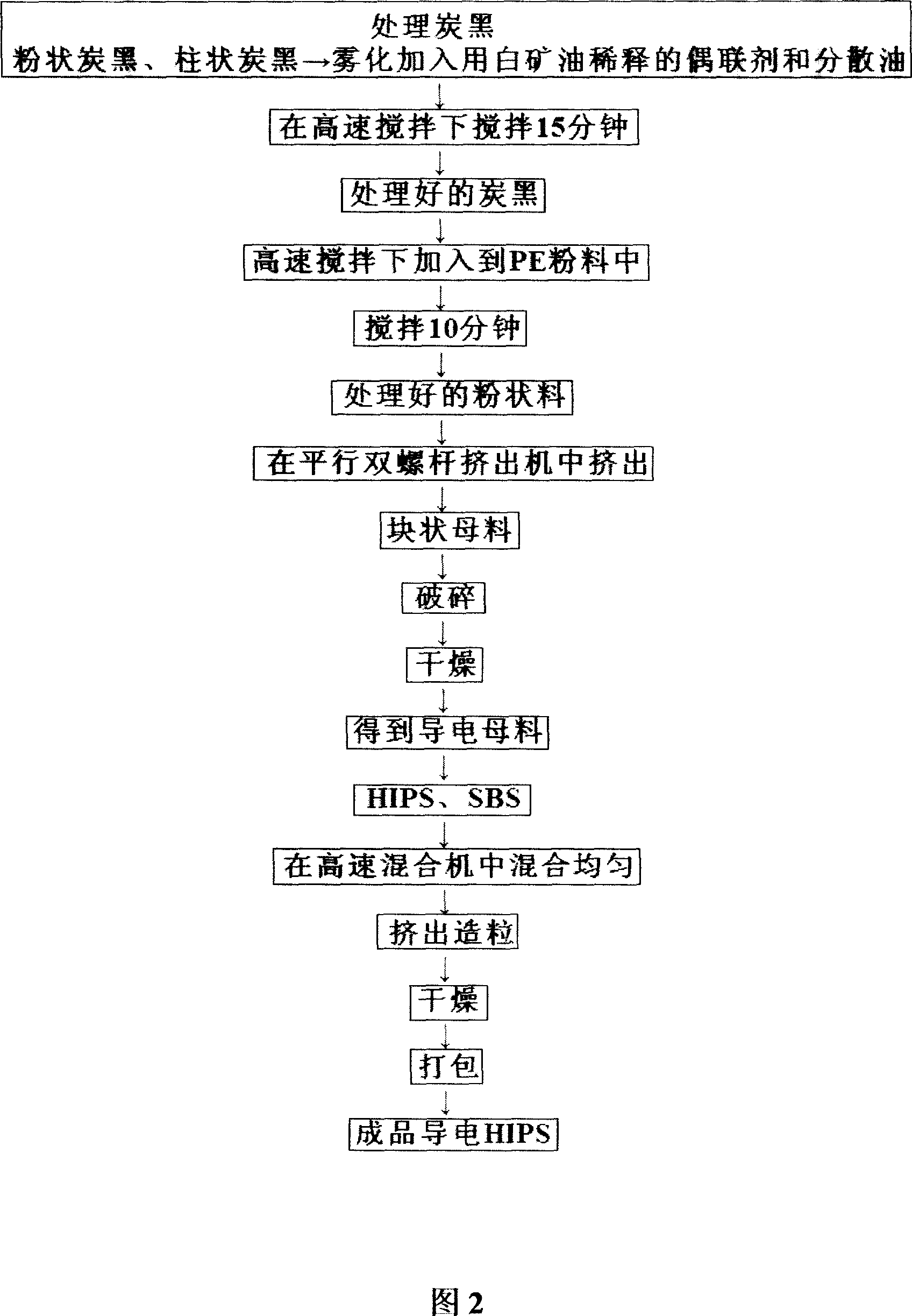

[0025] The preparation method of a kind of nano carbon black modified conductive plastic of the present invention, as shown in Figure 2, comprises the following steps:

[0026] A, select 30nm nano-scale carbon black as the conductive carrier, the treatment method is as follows: get 7.5% by weight of powdery carbon black and 7.5% by weight of columnar carbon black in a high-speed mixer, atomize with an atomizer Add the coupling agent of 0.5% by weight and the dispersing oil of 0.5% by weight, the coupling agent and the dispersing oil are all diluted with white mineral oil of 9% by weight, mixed for 15 minutes to obtain the processed carbon black ;

[0027] B. In a high-speed mixer, add 25% PE powder by weight, add the processed carbon black obtained in step A under high-speed stirring, and mix the two for 10 minutes; mix the powdery material in the extruder...

Embodiment 2

[0032] Embodiment two, the improved method of adjusting material softness and hardness

[0033] According to the requirements of different products, in the step C described in Example 1, GPPS, that is, general-purpose polystyrene, can also be added when mixing. The amount added is generally about 20%, which is used to adjust the softness and hardness of the material. If the material is soft, it can be adjusted to the required level with GPPS.

[0034] Test items

[0035] It can be seen that the conductive plastic obtained according to the preparation method of the present invention is comparable to similar products of Capote Corporation in the United States in terms of melt index, density, elongation, bending strength, heat distortion temperature, softening point, Rockwell hardness, etc. Ratio, the above properties are all close, and better than the products of domestic manufacturers; but the conductivity is better than (that is, the surface resistance is less than)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com