Air spring superlow frequency vibration isolating method and apparatus based on differential electromagnetic actuator

An electromagnetic actuator and air spring technology, applied in the direction of non-rotational vibration suppression, etc., can solve the problems of difficulty in implementation, difficult to use, affecting control accuracy, etc., achieving good low-frequency vibration isolation effect, reducing natural frequency, and strong bearing capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The system structure and working principle of an air spring ultra-low frequency vibration isolation method and device based on a differential electromagnetic actuator of the present invention are described in detail in conjunction with the embodiment and accompanying drawings as follows:

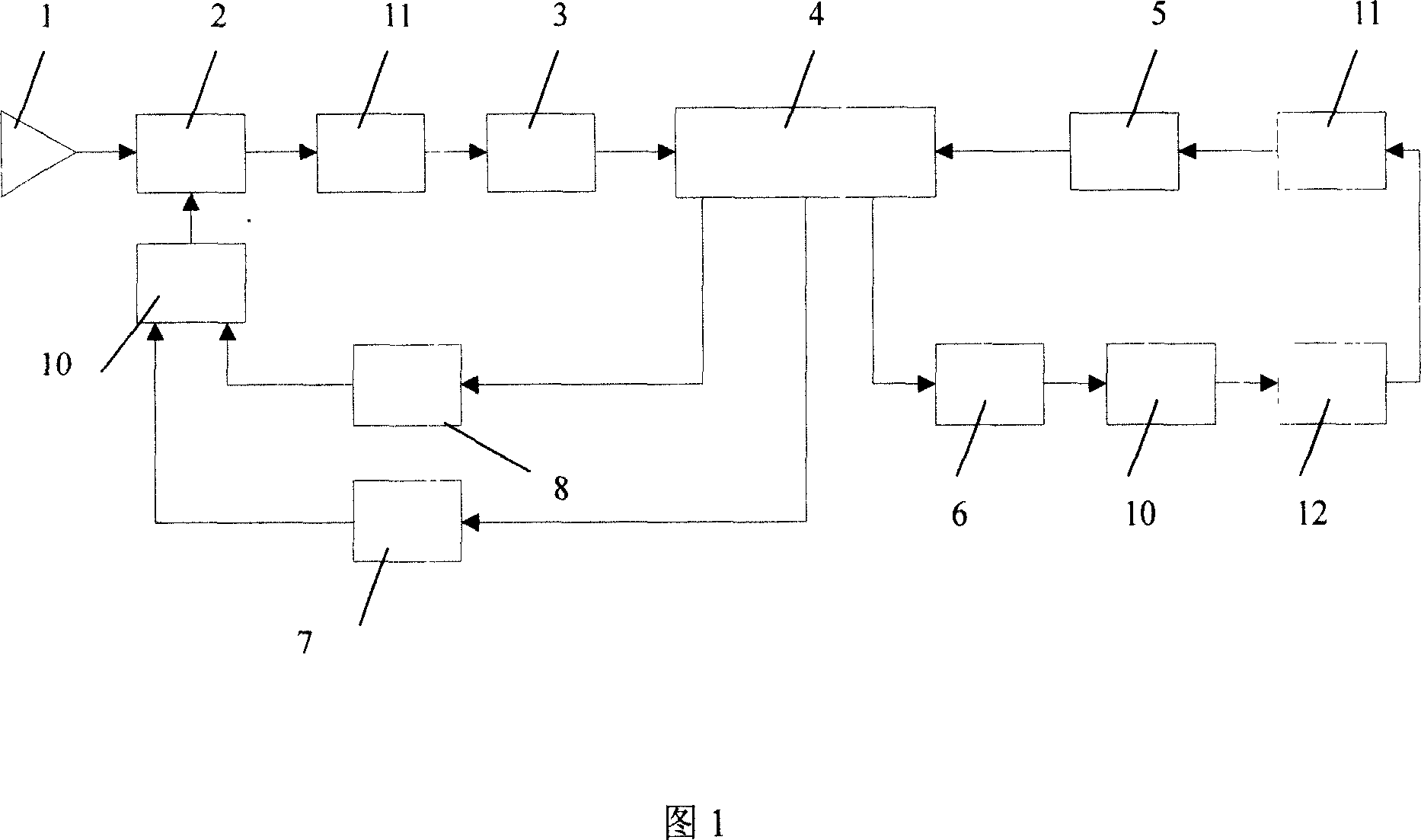

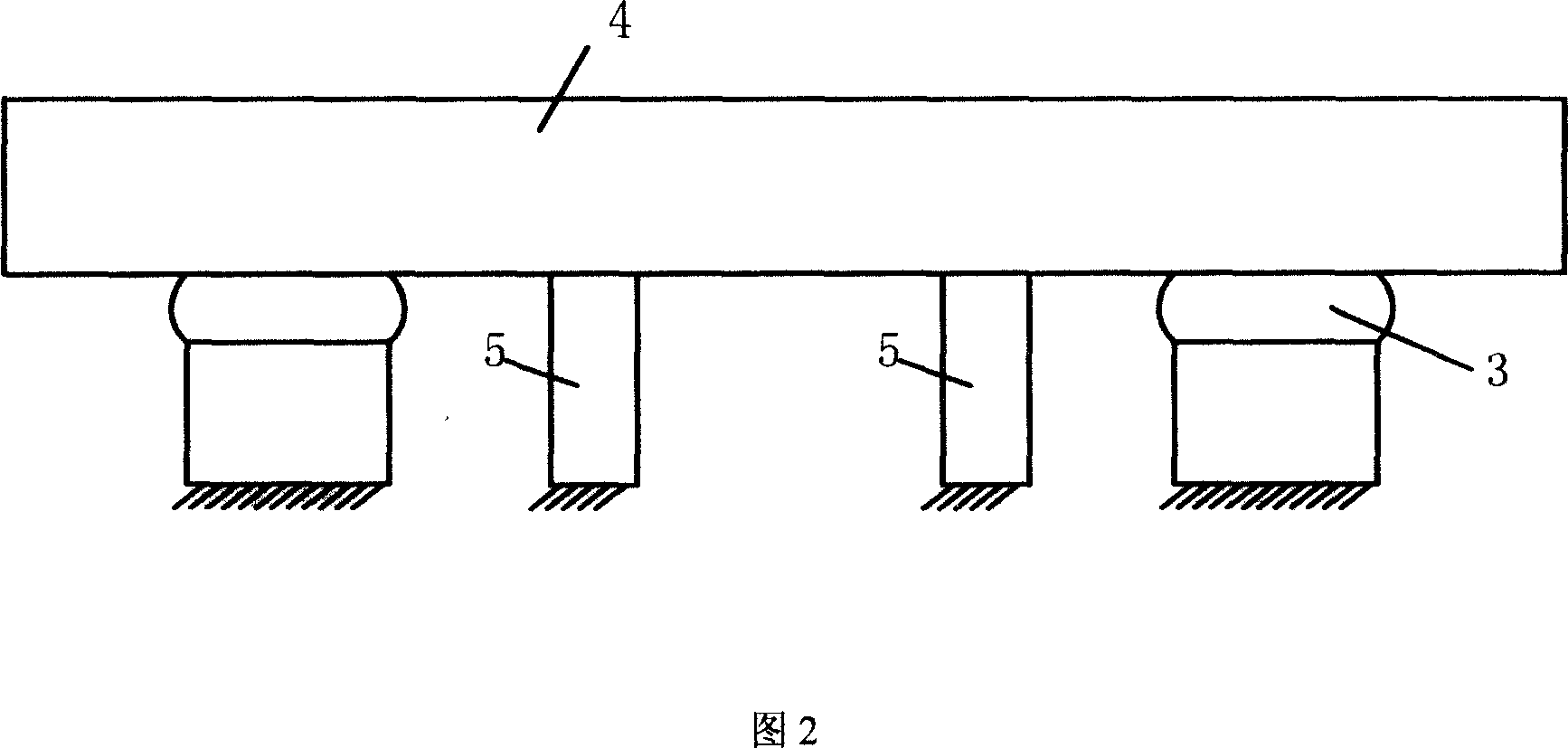

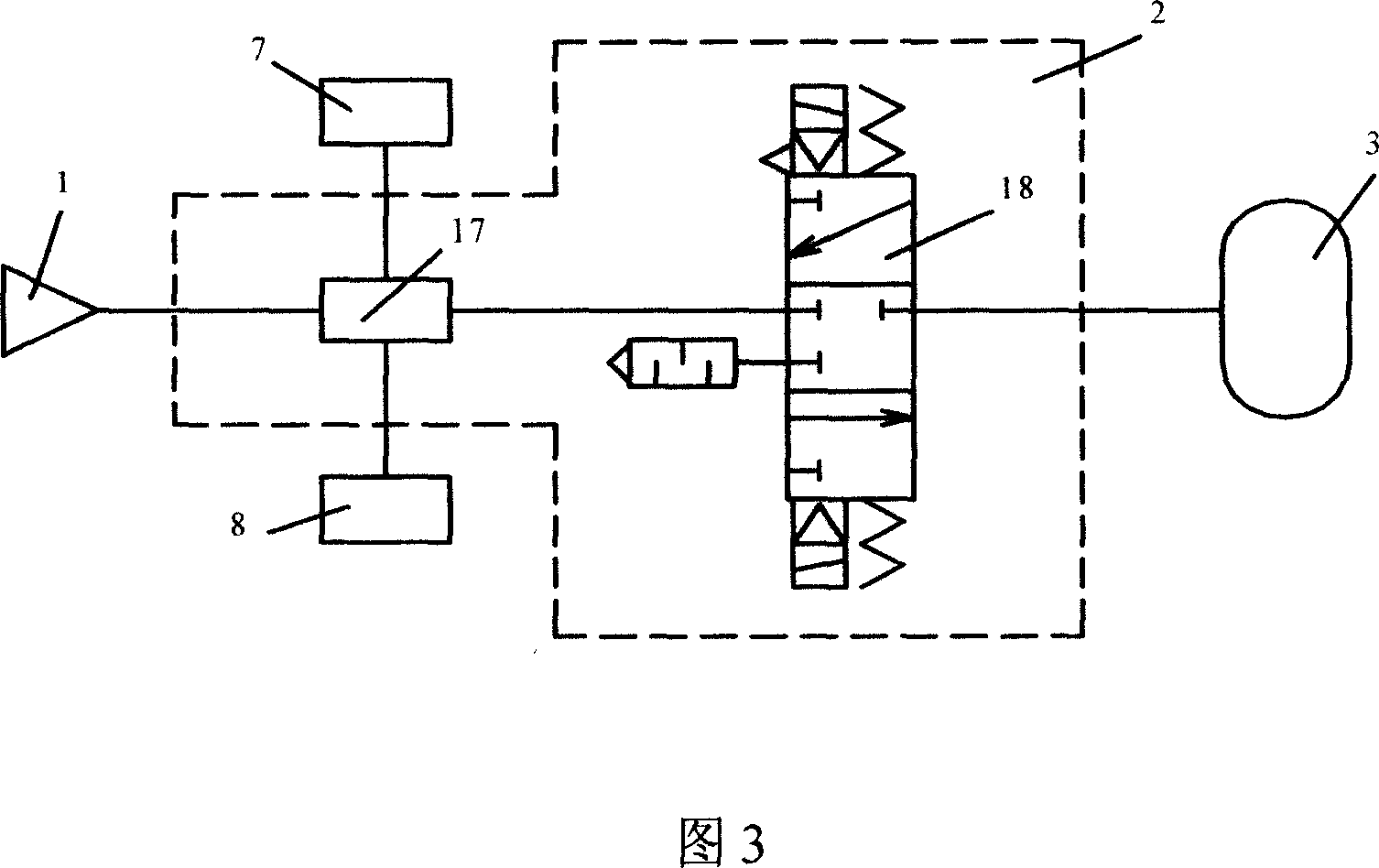

[0038] An embodiment of the air spring vibration isolation device based on the differential electromagnetic actuator of the present invention, the schematic diagram of the system principle is shown in Figure 1, including: 1 air supply system, 2 height control unit, 3 air spring system, 4 base body, 5 Differential electromagnetic actuator, 6 speed sensors, 7 force sensors, 8 displacement sensors, 9 power amplifiers, 10 analog / digital converters (A / D), 11 digital / analog converters (D / A), 12 controllers . The air supply end of the air supply system 1 is connected to the input end of the height control system 2, the output end of the height control system 2 is connected to the air intake ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com