Energy-consumption resetting shape memory alloy damper

A memory alloy and memory alloy wire technology, which is applied to building components, shockproof and other directions, can solve the problems of large residual deformation, weak energy dissipation capacity, narrow and long hysteresis curve, etc., to reduce residual deformation, low maintenance cost and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

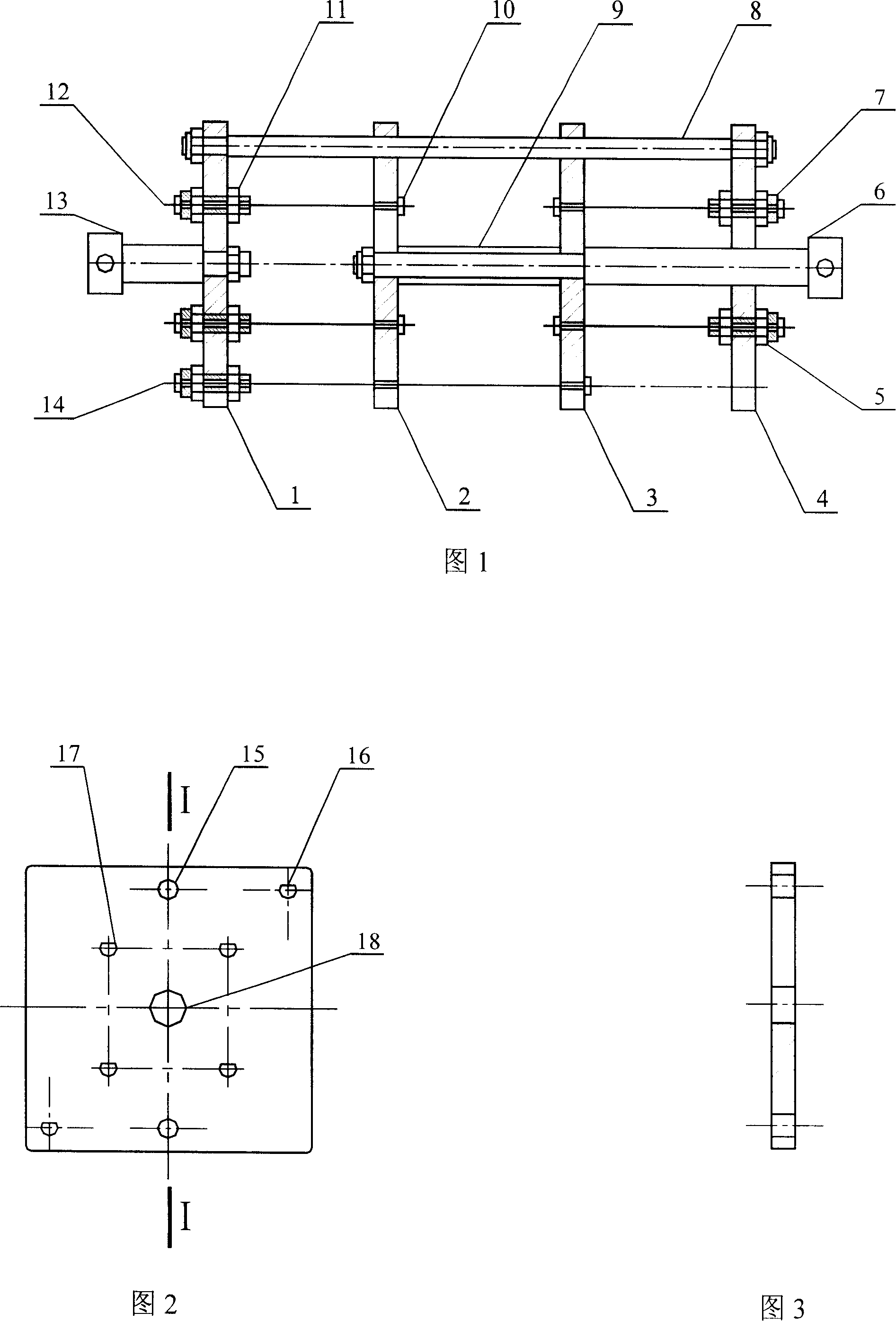

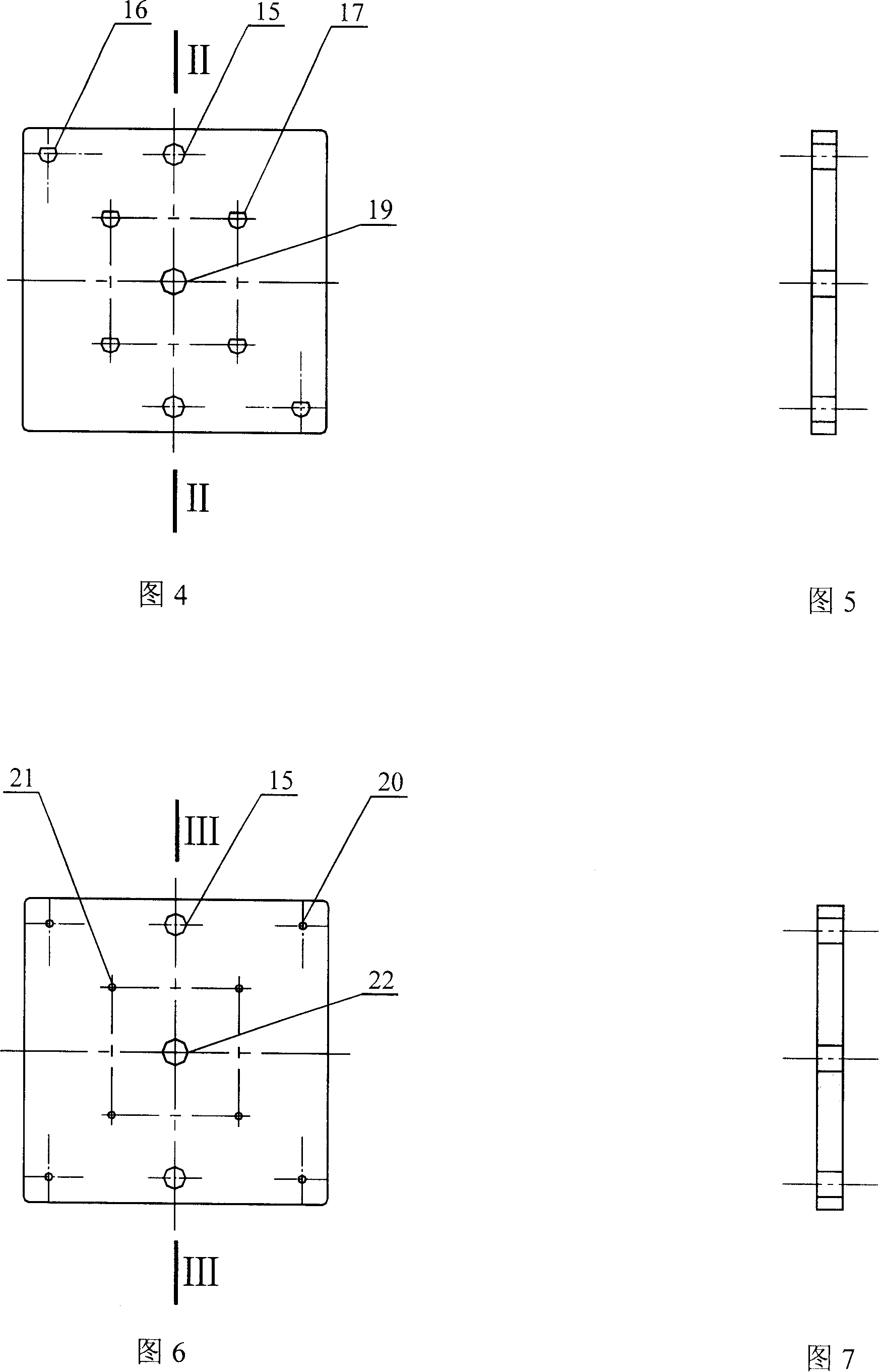

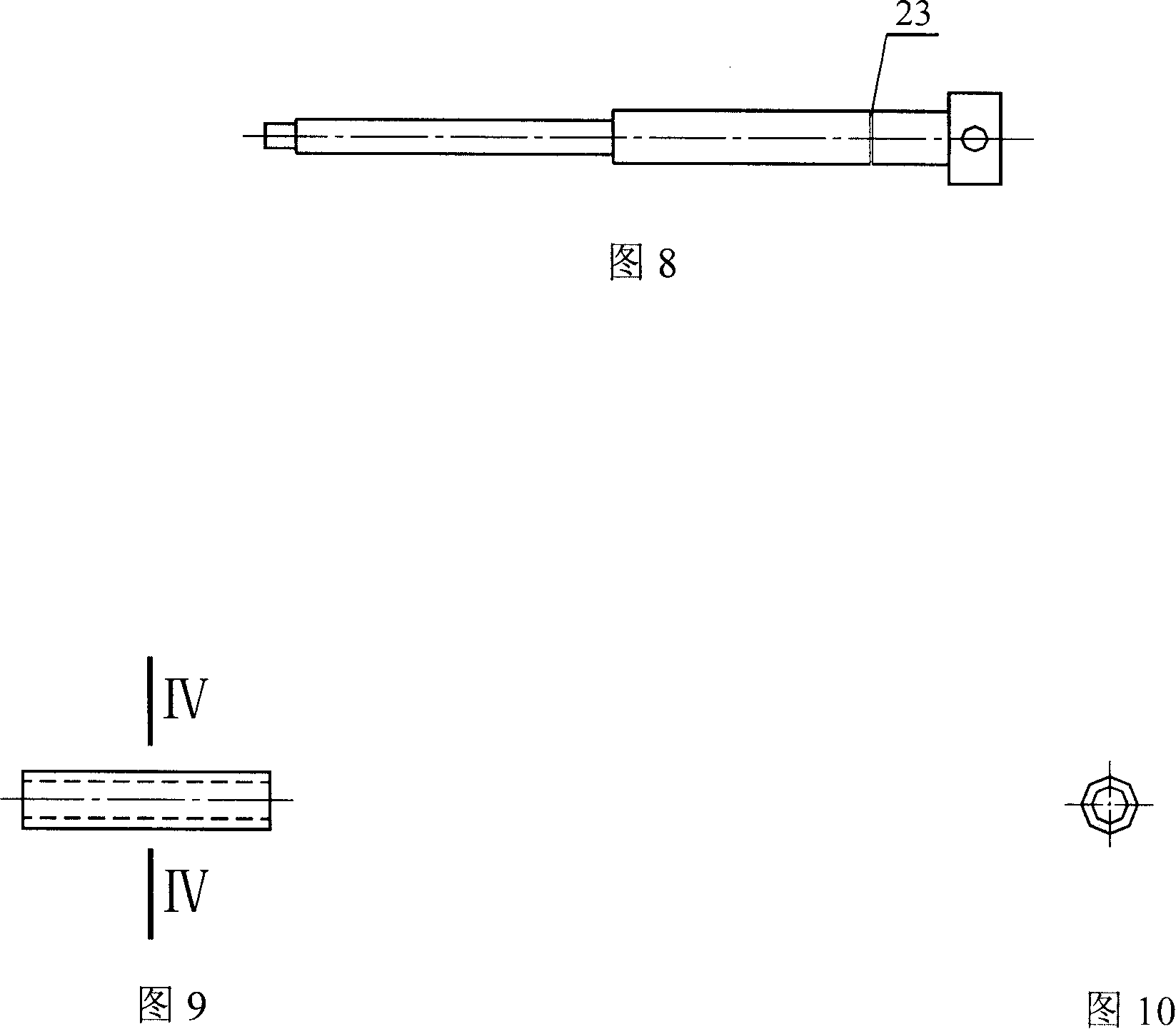

[0019] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

[0020] In Fig. 1, the center line and the bottom respectively show the central axis symmetric structure of the damper, in which the arrangement of the guide rod 8 and the energy-dissipating shape memory alloy wire 14 corresponds to the hole position of the corresponding steel plate. The installation process is carried out from inside to outside, and the specific implementation steps are as follows:

[0021] step 1

[0022] According to the requirements of vibration control, determine the material, size and quantity of each component of the damper.

[0023] step 2

[0024] The left inner steel plate 2 and the right inner steel plate 3 are sheathed on the guide rod 8, and are fixed on the pull rod 6 to form a sliding frame, and a sleeve 9 is arranged therebetween to limit the position. The left outer steel plate 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com