Tyre vulcanizing group control system

A technology for tire vulcanization and vulcanization machines, which is applied in the general control system, control/regulation system, program control, etc. It can solve the problems of cumbersome storage and management of historical data paper, complex data collection of multiple machines, and difficult search and retrieval. It is convenient for real-time monitoring, convenient control and fast transmission speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

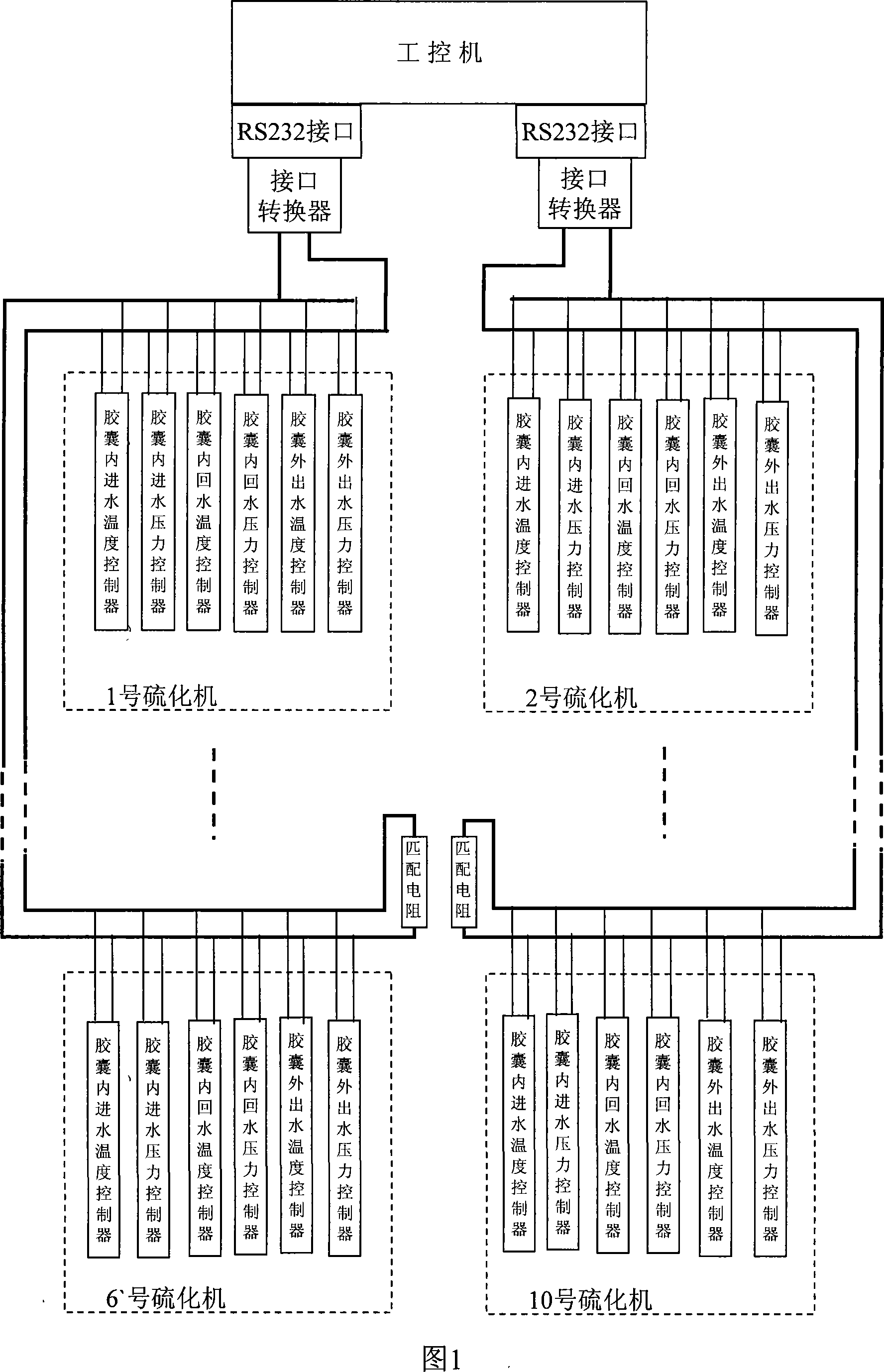

[0013] The structure of this embodiment of the tire vulcanization group control system is shown in Figure 1. The computer is an industrial computer connected with a display and a printing device. Two RS-232 interfaces are respectively connected with an interface converter and connected with an RS-485 bus. The RS-232 / RS-485 interface converter converts the data transmit (TD) and data receive (RD) signals of the RS-232C serial port into two-wire balanced half-duplex RS-485 signals. The 10 vulcanizing machines are divided into two groups, with 5 vulcanizing machines in each group. Each vulcanizer is connected to the inlet and outlet of the high-temperature medium pipeline in the capsule and installed outside the capsule in the vulcanization tank. Temperature sensors and pressure sensors are respectively connected to AI temperature controllers and AI pressure controllers. AI temperature and pressure controllers Connect with the solenoid valves on the relevant pipelines respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com