Powder-spraying chamber for electrostatic powder spray coated

A spraying equipment, electrostatic powder technology, applied in electrostatic spraying device, spraying device and other directions, can solve the problems of intolerance to wear, drop of powder on workpiece, damage of spraying room, etc., to achieve simple and convenient operation, solve connection problems, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

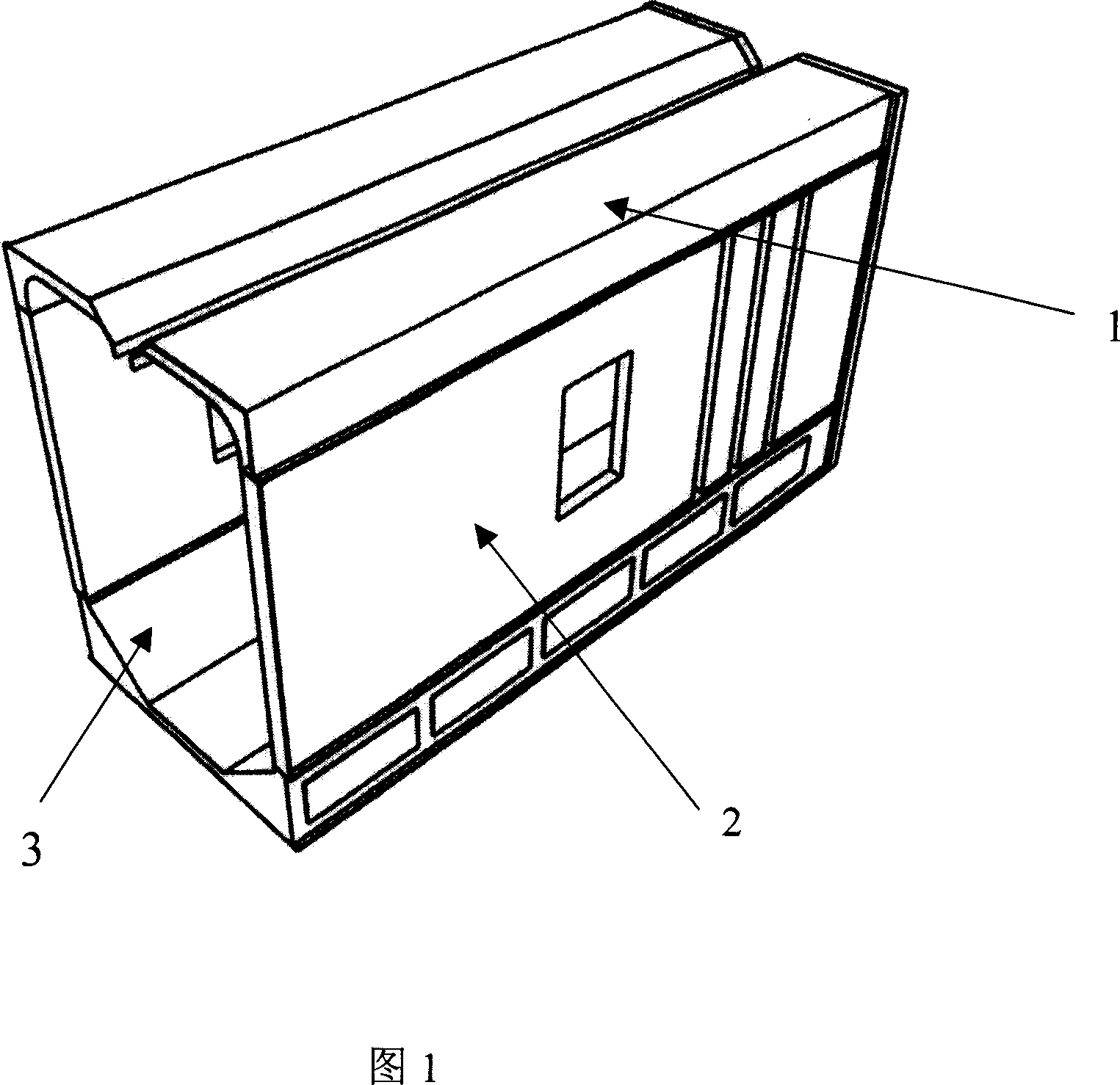

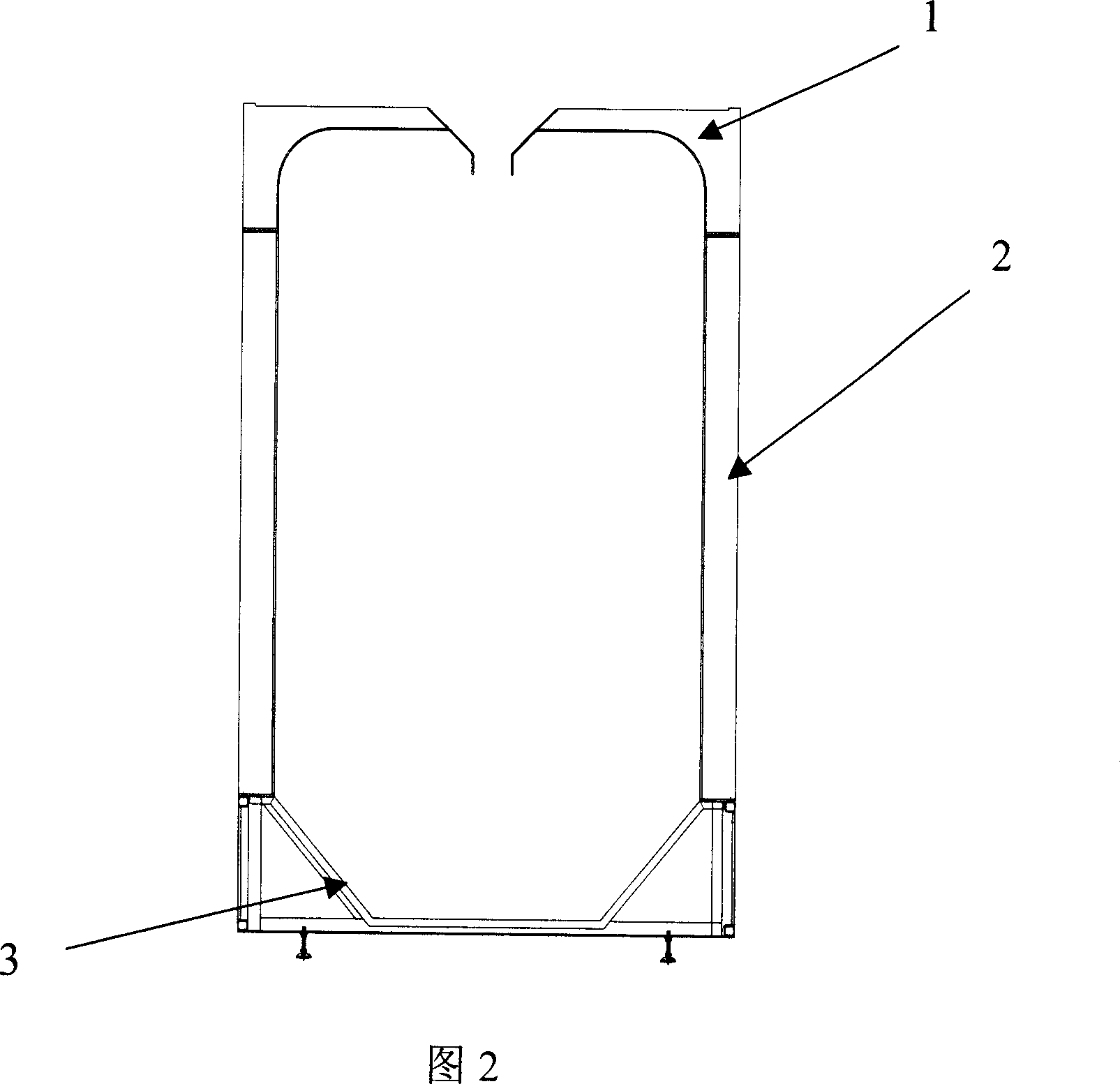

[0017] As shown in Fig. 1 and Fig. 2, the powder spraying chamber of a kind of electrostatic powder spraying equipment of the present invention is composed of the upper top wall 1 and the side wall 2 and the bottom wall 3 of the lower part. The wall 2 is made of insulating engineering plastics, and the bottom wall 3 is made of metal material. The bottom wall 3 bottom wall is " "type or form" "Type. The transition between the top wall 1 and the side wall 2 is rounded. The radius of the rounded corner between the top wall 1 and the side wall 2 is 50-400 mm, and electrostatic spraying powder is not easy to deposit at the corner. The side wall 2 and the bottom wall 3 are fastened by bolts. The top wall 1 and the side wall 2 are made of hollow sandwich engineering plastics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com