Device and method for realtime controlling self-adaptive temperature injection-mould machine and its temperature-adjusting circuit

A real-time control and self-adaptive technology, which is applied in the field of self-adaptive temperature real-time control injection molding machine controllers, can solve problems such as easy to generate large oscillations and large changes in response curves, and achieve good reliability, strong adaptability, quality and stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

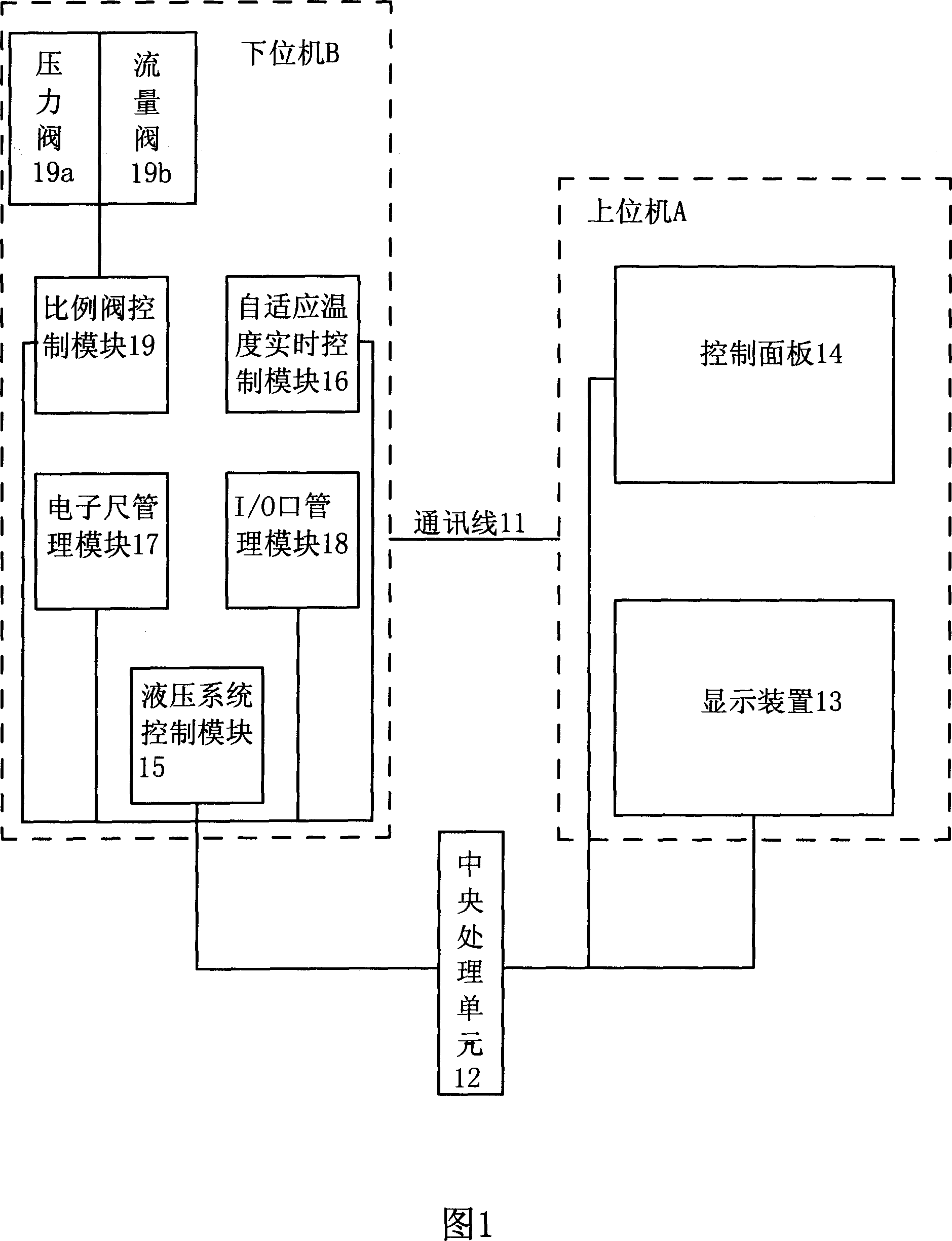

[0038] As shown in Figure 1, the adaptive temperature real-time control injection molding machine controller includes an upper computer A for monitoring and a lower computer B for execution. The upper computer A and the lower computer B are connected through a communication line 11, and the central The processing unit 12 performs data information processing. The upper computer A includes a display device 13 connected to the central processing unit 12 for displaying working status, and a control panel 14 for controlling operation and parameter setting management. The lower computer B includes a hydraulic system control module 15 connected to the central processing unit 12 for controlling the work of the hydraulic system, an adaptive temperature real-time control module 16 for barrel temperature measurement and adaptive temperature control, and a real-time control module 16 for An electronic ruler management module 17 for controlling the electronic ruler, an I / O port management ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com